一、产品概述

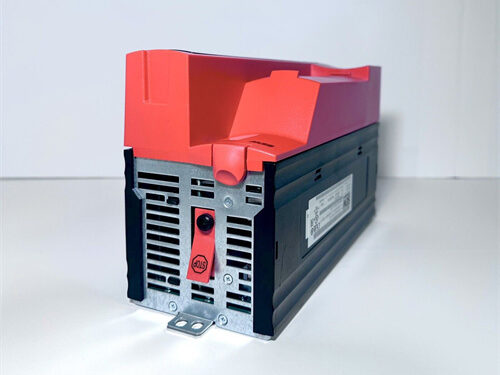

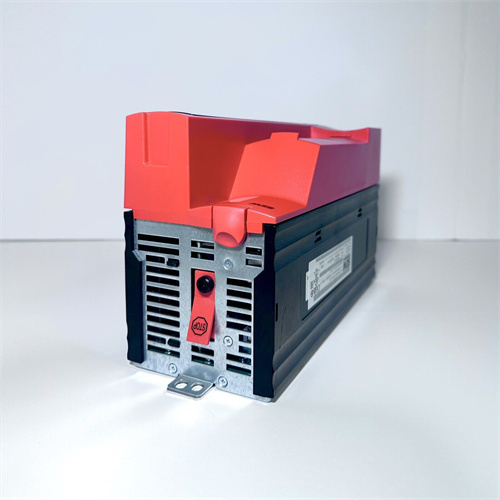

SEW MDX61B0370-503-4-0T是德国SEW公司推出的高性能工业变频器,专为中大型电机驱动设计,支持宽电压输入与高功率输出。其核心功能包括高精度调速、多模式控制、智能通信及四象限运行能力,适用于物流仓储、建材生产、冶金化工等重载工业场景。

二、核心参数

电气规格

输入电压:三相AC 380-500V(50Hz/60Hz自适应),支持宽电压输入。

输出功率:适配37-45kW电机,过载能力达150%(持续60秒),175%短时运行。

输出频率:0-400Hz连续可调,支持低速大转矩输出。

控制特性

控制方式:支持矢量控制(VFC/FC)、V/F控制及手动操控,可实现转速/转矩双闭环控制。

动态响应:转矩响应时间≤50ms,速度控制精度≤0.5%。

编码器支持:兼容Sin/Cos、TTL、Hiperface等编码器类型,支持位置反馈精度±0.1°。

接口与通信

输入输出接口:8路数字输入、5路数字输出、1路模拟输入;可扩展至8路数字输入/8路数字输出、2路模拟输入。

通信协议:集成RS485/Modbus-RTU,支持PROFIBUS、EtherNet/IP、EtherCat等工业总线扩展。

三、功能特点

1.高精度与稳定性

矢量控制技术:通过磁场定向控制优化电机性能,实现高动态响应与低速稳定性,适用于重载启停场景(如水泥回转窑风机)。

闭环控制:支持编码器反馈,提升定位精度(如物流堆垛机货叉定位误差≤2mm)。

2.模块化设计

扩展性:可选配PLC卡、同步控制器、制动斩波器等模块,适配复杂应用场景(如四象限运行需求)。

接口兼容性:支持多种总线协议,无缝集成至PLC或SCADA系统。

3.保护与安全

多重保护:过流、过压、欠压、过热、短路等保护,故障响应时间<10ms。

安全功能:符合EN 954-1安全标准,支持“安全停止”功能。

4.环境适应性

防护等级:IP20(标准柜体安装),可选配IP54防护套件适应恶劣环境。

工作温度:-10°C~50°C(部分工业级型号支持扩展温度范围)。

抗干扰设计:内置EMC滤波器,适应强电磁干扰环境。

1.Product Overview

SEW MDX61B0370-503-4-0T is a high-performance industrial frequency converter launched by SEW,Germany.It is designed for medium and large motor drives and supports wide voltage input and high power output.Its core functions include high-precision speed regulation,multi-mode control,intelligent communication and four-quadrant operation capabilities,and are suitable for heavy-duty industrial scenarios such as logistics and warehousing,building materials production,metallurgy and chemical industry.

2.Core parameters

Electrical specifications

Input voltage:three-phase AC 380-500V(50Hz/60Hz adaptive),supports wide voltage input.

Output power:adapted to 37-45kW motor,overload capacity up to 150%(lasting 60 seconds),175%short-term operation.

Output frequency:0-400Hz continuously adjustable,supporting low-speed and high-torque output.

Control Features

Control method:supports vector control(VFC/FC),V/F control and manual control,and can realize dual closed-loop control of speed/torque.

Dynamic response:Torque response time≤50ms,speed control accuracy≤0.5%.

Encoder support:compatible with encoder types such as Sin/Cos,TTL,Hiperface,etc.,and supports position feedback accuracy±0.1°.

Interface and communication

Input and output interfaces:8 digital inputs,5 digital outputs,1 analog input;can be expanded to 8 digital inputs/8 digital outputs,2 analog inputs.

Communication protocol:Integrate RS485/Modbus-RTU,supports industrial bus expansion such as PROFIBUS,EtherNet/IP,EtherCat,etc.

3.Functional characteristics

1.High precision and stability

Vector control technology:optimizes motor performance through magnetic field directional control,achieves high dynamic response and low speed stability,and is suitable for heavy-load start-stop scenarios(such as cement rotary kiln fans).

Closed-loop control:supports encoder feedback to improve positioning accuracy(such as the positioning error of logistics stacker forks≤2mm).

2.Modular design

Extensibility:It can be equipped with PLC card,synchronization controller,brake chopper and other modules to adapt to complex application scenarios(such as four-quadrant operation requirements).

Interface compatibility:Supports multiple bus protocols,seamless integration into PLC or SCADA systems.

3.Protection and safety

Multiple protection:overcurrent,overvoltage,undervoltage,overheating,short circuit and other protection,fault response time is less than 10ms.

Safety function:Comply with EN 954-1 safety standard and supports the”safe stop”function.

4.Environmental adaptability

Protection level:IP20(standard cabinet installation),optional IP54 protection kit can be used to adapt to harsh environments.

Operating temperature:-10°C~50°C(some industrial-grade models support extended temperature range).

Anti-interference design:built-in EMC filter to adapt to strong electromagnetic interference environment.