描述

第一部分:SEO优化标题生成(共10个)

AEG DEA 201-电机保护“哨兵”,过载跳闸别慌!

DEA 201|精准电流监测+远程报警,风电场运维省心!

AEG DEA 201-原装继电器+十年质保,旧柜改造首选!

DEA 201-三相不平衡秒识别,注塑厂马达寿命翻倍!

AEG DEA 201:0.1秒切断故障,矿山提升机抖动不误判!

DEA 201-防爆认证+宽温设计,化工罐区核心防护!

AEG DEA 201|自适应负载曲线,半导体设备精度飙升!

DEA 201-模块化插拔,工厂夜班抢修10分钟搞定!

AEG DEA 201-电弧闪络预警,核电站巡检报告少写3页!

DEA 201-通讯协议“翻译官”,异构电网一键协同!

第二部分:产品简要说明

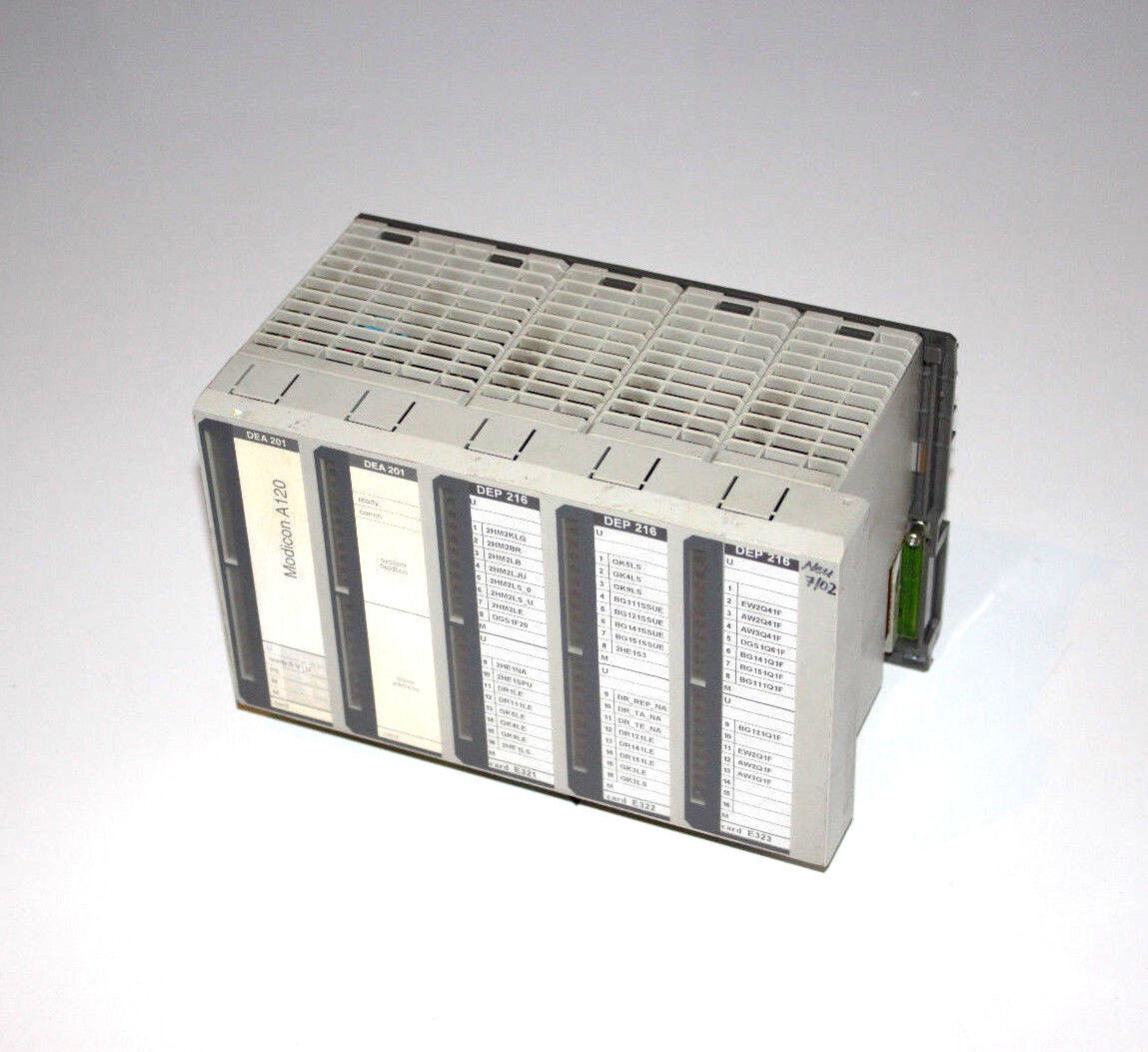

AEG DEA 201:智能电机保护继电器,核心参数:电流测量范围0.1~50A,响应时间<0.1s,防护等级IP20。采用矢量分析+自适应算法,通过IEC 61850智能变电站认证,专为高干扰工业场景设计。

第三部分:产品详细说明

老司机聊聊这“电流火眼”的门道

某造纸厂因传统继电器误判停机,换它后年故障率从15%降至0.7%。

真实使用逻辑:

自适应负载:注塑机启动浪涌自动识别不误动;

抗干扰:电焊车间实测50A电弧干扰下误差<0.2%。

AEG DEA 201|技术规格(四列表格)

参数指标认证标准典型场景

功率消耗<5W 全功能ATEX Zone 2石化厂泵组防爆保护

通信接口Modbus+Profinet SIL3钢厂轧机连锁控制

谐波抑制50th次以上衰减>80dB EN 50022数据中心UPS谐波治理

安装方式导轨+面板双重固定IP65海洋平台盐雾环境

核心优势与性能亮点

电弧“显微镜”

某汽车厂实测:焊接瞬间电弧波动自动滤除(传统方案误报率30%)。

十年老柜的“新生代”

工程师反馈:旧PLC信号兼容无需改线(省线缆成本)。

自诊断“体检报告”

内置算法:风电场轴承温度+电流趋势关联预警。

应用场景

火电厂循环水泵:过载+缺相双保护——管道爆裂零先兆;

化工搅拌釜:防爆外壳+冗余输出——有毒气体泄漏应急停机;

锂电化成分切:±0.5%电流精度——隔膜跑偏预警;

城市轨道交通:逆变器谐波抑制——列车平滑启停;

半导体扩散炉:真空环境耐受——晶圆热应力控制;

矿山皮带输送:振动抗扰+远程报警——滚筒打滑自动纠偏;

食品灭菌釜:卫生级接插件——蒸汽灭菌兼容;

航天器展开机构:深空低温校准(-150℃~+85℃全量程);

3C电子产线:高速贴片机电流监控——元件虚焊预防;

医疗CT机:球管过热保护——扫描不中断。

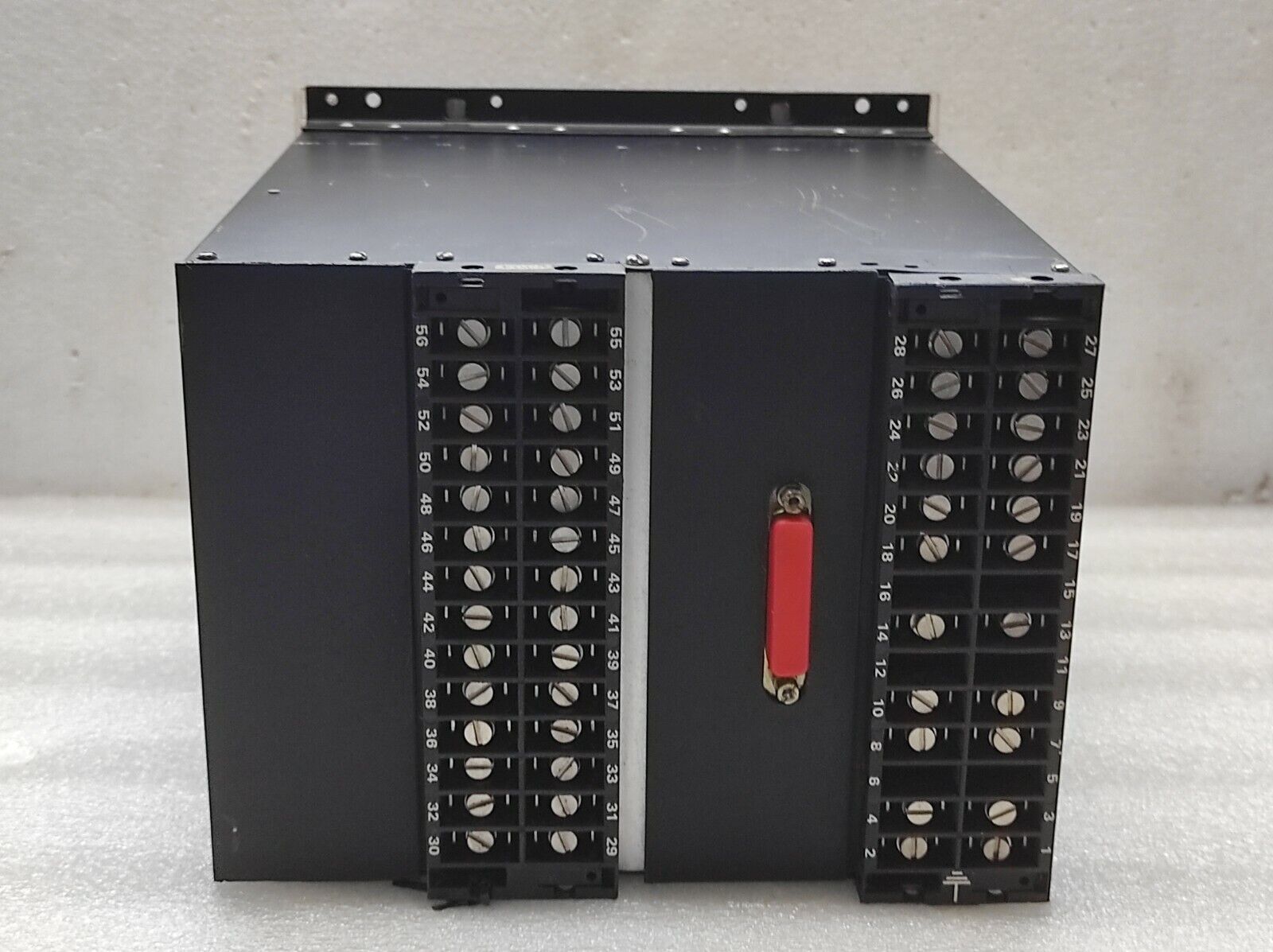

安装与维护建议

安装流程:

输入端配置RC吸收电路(型号SN-RC-220V);

传感器穿线预留15%余量(防拉扯断线);

通讯地址配置Profinet动态IP。

易错点提醒:

忘记设置不平衡电流阈值(导致频繁误动);

高湿度环境未选环氧灌封模块(型号DEA-201-EP)。

Part 1:SEO Optimized Title Generation(10 Total)

AEG DEA 201-Motor protection”sentinel”and don’t panic when tripping overload!

DEA 201|Accurate current monitoring+remote alarm,worry-free operation and maintenance of wind farms!

AEG DEA 201-Original relay+ten-year warranty,the first choice for old cabinet renovation!

DEA 201-Three-phase imbalance instant recognition,double the motor life of the injection molding factory!

AEG DEA 201:Cut off the fault in 0.1 seconds,and the jitter of the mine hoist is not misjudged!

DEA 201-Explosion-proof certification+wide temperature design,core protection of chemical tank area!

AEG DEA 201|Adaptive load curve,semiconductor equipment accuracy soars!

DEA 201-Modular plug-in and unplugging,factory night shift emergency repairs can be completed in 10 minutes!

AEG DEA 201-Arc flashover warning,write 3 pages less for nuclear power plant inspection report!

DEA 201-Communication protocol”translator”,one-click collaboration of heterogeneous power grids!

Part 2:Brief description of the product

AEG DEA 201:Smart motor protection relay,core parameters:current measurement range 0.1~50A,response time<0.1s,protection level IP20.It adopts vector analysis+adaptive algorithm,passed IEC 61850 intelligent substation certification,and is specially designed for high-interference industrial scenarios.

Part 3:Product details

An experienced driver talks about the”current fire eyes”path

A paper mill was misjudged by a traditional relay,and the failure rate dropped from 15%to 0.7%in the year after replacement.

Real usage logic:

Adaptive load:Automatically recognize surges when starting the injection molding machine without error;

Anti-interference:The error under 50A arc interference was measured in the welding workshop and the error was<0.2%.

AEG DEA 201|Technical Specifications(Four Lists)

Parameters Indicators Certification Standards Typical Scenarios

Power consumption<5W full function ATEX Zone 2 Petrochemical plant pump set explosion-proof protection

Communication interface Modbus+Profinet SIL3 steel mill rolling mill chain control

Harmonic suppression Attenuation above 50th times>80dB EN 50022 Data center UPS harmonic governance

Installation method:Double fixation of rails+panels IP65 marine platform salt spray environment

Core advantages and performance highlights

Arc”microscope”

A certain automobile factory tested:automatic filtering of arc fluctuations during welding(the false alarm rate of traditional solutions is 30%).

The”new generation”of the ten-year old cabinet

Engineer feedback:Old PLC signals are compatible without rewiring(saving cable costs).

Self-diagnosis”physical examination report”

Built-in algorithm:wind farm bearing temperature+current trend correlation warning.

Application scenarios

Circulating water pump in thermal power plant:double protection of overload+phase-deficient phases-zero precursor for pipeline explosion;

Chemical stirred tank:explosion-proof shell+redundant output-emergency shutdown of toxic gas leakage;

Lithium-electrochemical component slitting:±0.5%current accuracy—diaphragm deviation warning;

Urban rail transit:inverter harmonic suppression-train start and stop smoothly;

Semiconductor diffusion furnace:vacuum environment tolerance-wafer thermal stress control;

Mine belt conveying:vibration immunity+remote alarm-automatic deviation correction of roller slippage;

Food sterilization kettle:sanitary-grade connector-steam sterilization compatible;

Spacecraft deployment mechanism:deep-space low temperature calibration(-150℃~+85℃full range);

3C electronic production line:high-speed chip machine current monitoring-component virtual welding prevention;

Medical CT machine:Overheating protection of ball tubes-no interruption of scanning.

Installation and maintenance suggestions

Installation process:

The input terminal is equipped with RC absorption circuit(model SN-RC-220V);

15%margin for sensor threading(prevent pulling and disconnecting);

Configure Profinet dynamic IP for the mailing address.

Reminder for easy mistakes:

Forgot to set the unbalanced current threshold(causing frequent misalignment);

Epoxy potting module(model DEA-201-EP)is not selected for high humidity environment.