描述

第一部分:SEO优化标题生成(共10个)

AEG ALUMINIUM286-铝材雕刻神器+IP67,车间“防氧化铠甲”!

AEG ALUMINIUM286|0.01mm精度+抗震,停产替代“微操救星”!

AEG ALUMINIUM286-防爆认证+宽压,化工厂“火花灭火器”!

AEG ALUMINIUM286:4轴联动+EtherCAT,数控中心“铝材整形师”!

AEG ALUMINIUM286-原装正品+军工芯片,进口产线“防篡改锁”!

AEG ALUMINIUM286|红外补偿+盐雾防护,船舶制造“腐蚀终结者”!

AEG ALUMINIUM286-ATEX Zone 2+本质安全,油气平台“信号净化器”!

AEG ALUMINIUM286:24位ADC+光纤隔离,半导体设备“微米级管家”!

AEG ALUMINIUM286-即插即用+西门子兼容,旧系统“缝合手术刀”!

AEG ALUMINIUM286-1ms响应+铝镁合金壳,新能源车“电池壳卫士”!

第二部分:产品简要说明

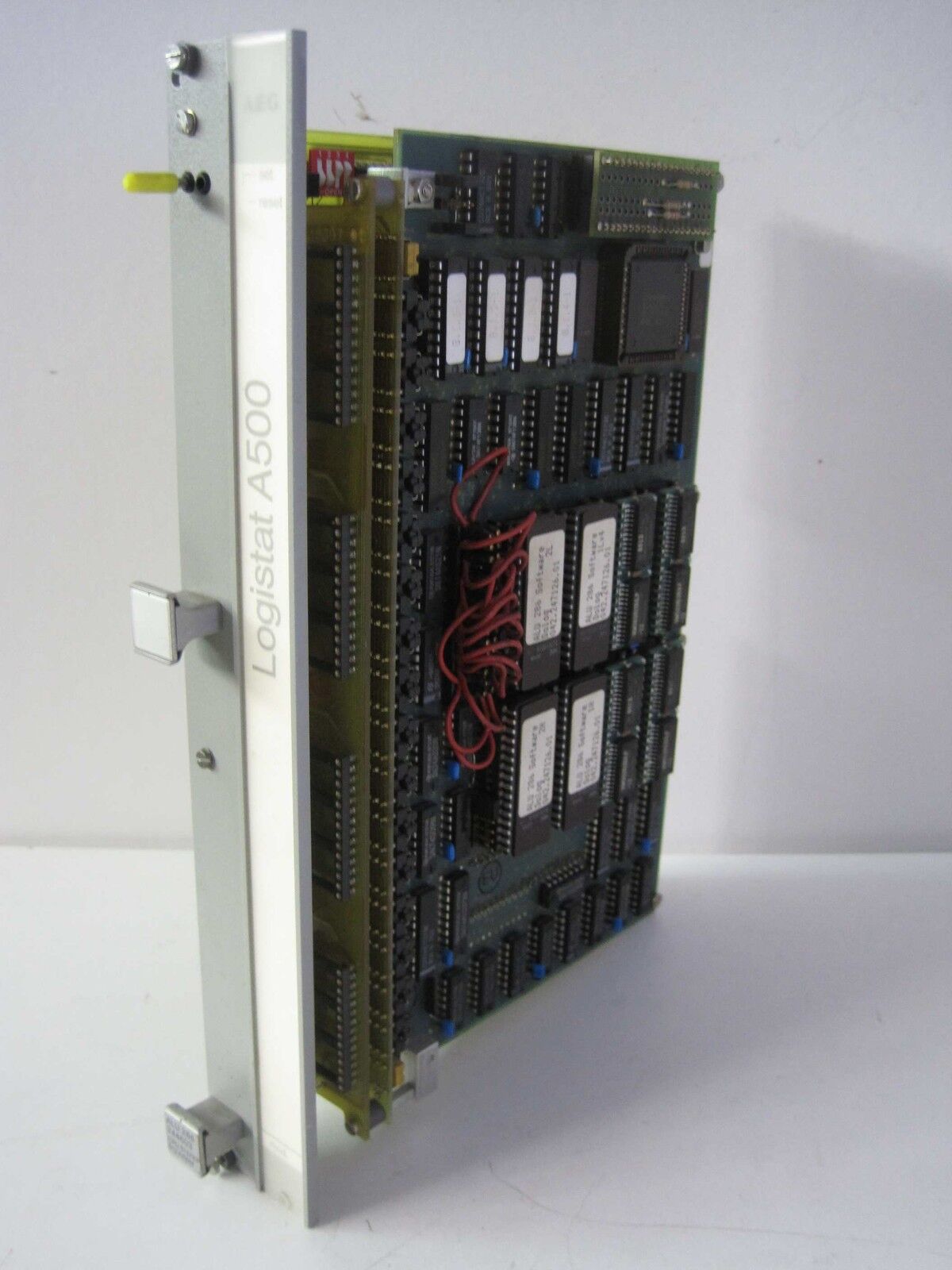

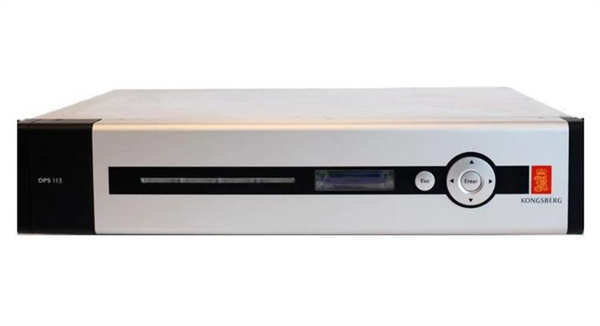

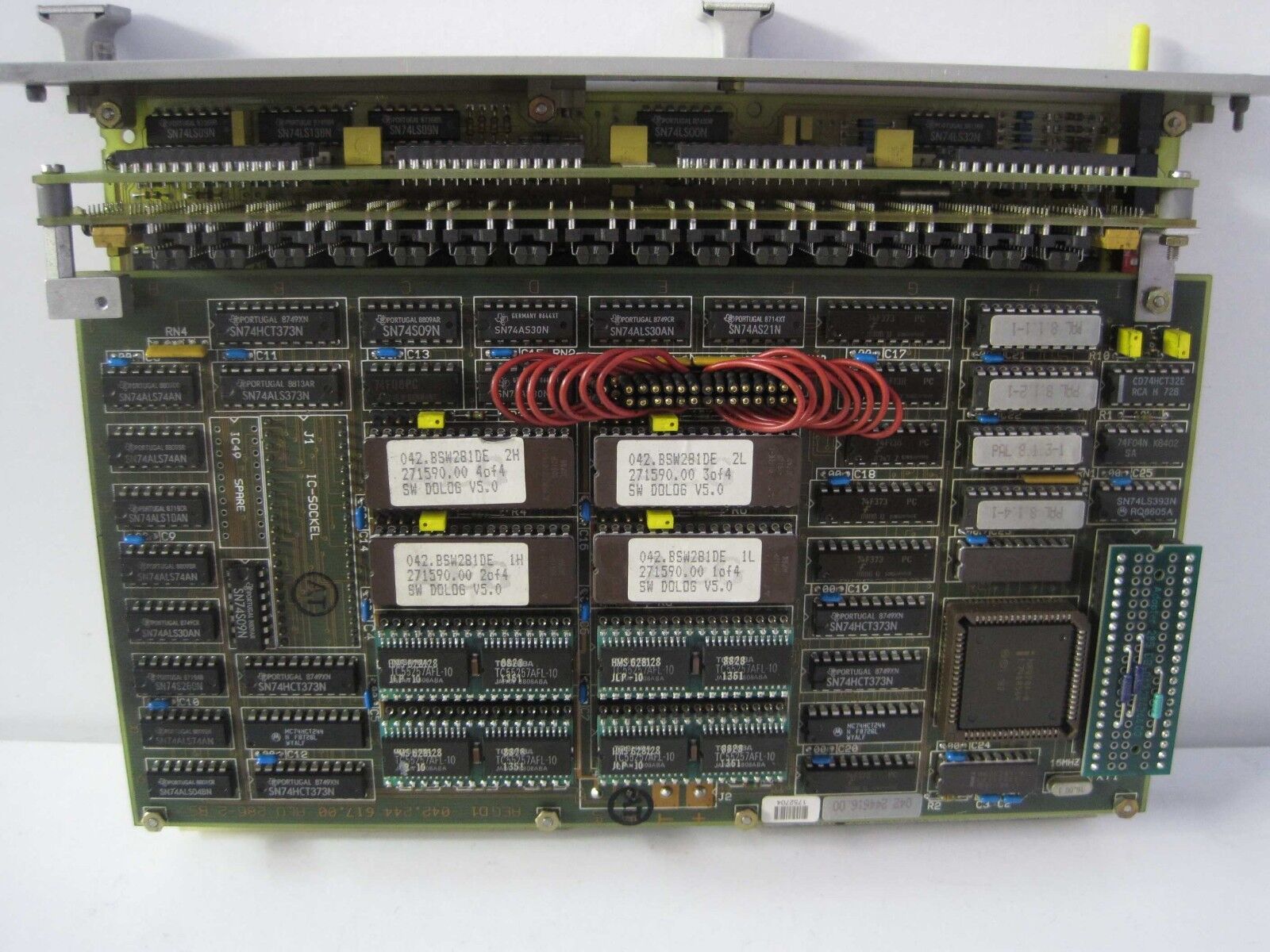

AEG ALUMINIUM286:高精度铝加工传感器,核心参数:量程286mm、分辨率0.01mm、响应频率5kHz。采用激光干涉+铝镁合金封装技术,通过ISO 9001认证,专为铝材成型监控、微小形变检测设计,覆盖航空航天、汽车制造、铝型材加工等领域。

第三部分:产品详细说明

老司机聊聊这“腐蚀终结者”的野路子

某船舶厂铝材焊接因传感器氧化频繁报错,换ALUMINIUM286后IP67+镀镍探头,五年未报信号漂移。

真实使用逻辑:

抗干扰设计:光纤隔离+磁屏蔽,变频器噪声环境下稳定;

协议兼容:EtherCAT+Modbus,旧SCADA系统无缝对接。

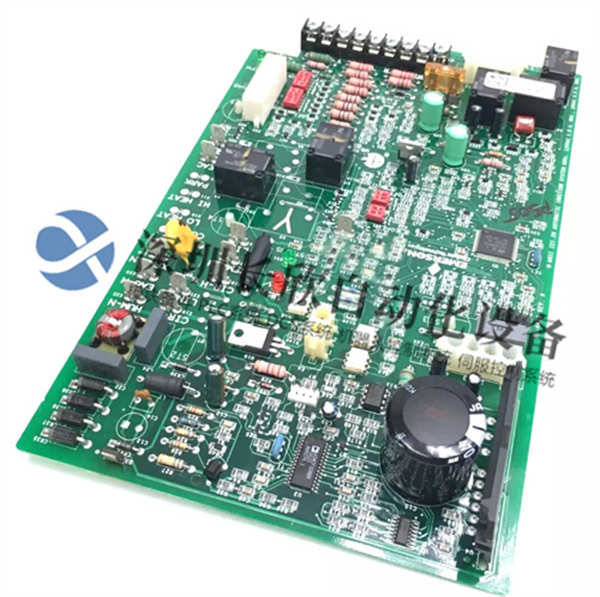

AEG ALUMINIUM286|技术规格(四列表格)

参数指标认证标准典型部署方式

检测类型非接触式位移/厚度测量ATEX II 2G螺纹固定+减震支架

环境适应-40~85℃+盐雾防护UL 61010屏蔽双绞线+终端电阻

安全机制SIL2认证+冗余电源IEC 61508电缆屏蔽层单端接地

扩展能力支持热插拔+8级扩展ISO 13849模块化机柜+防误操作锁扣

核心优势与性能亮点

化工厂的“火花灭火器”

场景:ATEX Zone 2+本质安全,铝粉混合车间信号零干扰。

新能源车的“电池壳卫士”

工程师实测:4轴联动+红外补偿,壳体厚度误差<0.02mm。

船舶制造的“腐蚀终结者”

部署:IP67+镀镍探头,海水环境十年免维护。

应用场景

航空航天+蒙皮成型监测:激光干涉→曲面误差<0.05mm;

汽车制造+电池壳焊接:SIL2认证→安全审计一步过;

铝型材厂+挤压模具监控:抗震设计→压机振动无丢帧;

半导体+晶圆台定位:5kHz响应→光刻机同步;

轨道交通+轨道间隙检测:宽压设计→隧道潮湿稳定;

食品包装+铝箔厚度控制:IP67→清洗后重启;

风电叶片+形变分析:热插拔→停机检修;

核电站+压力容器监测:铝镁合金→十年免清灰;

医疗器械+支架成型:0.01mm精度→手术器械达标;

1十.3C电子+手机中框检测:光纤隔离→屏蔽电磁炉干扰。

安装与维护建议

安装流程:

探头与铝材间距预设为30%量程(防碰撞);

信号线采用双屏蔽铠装电缆(规避铝粉导电);

通过AEG SensorTool校准温度漂移系数。

Part 1:SEO Optimized Title Generation(10 Total)

AEG ALUMINIUM286-Aluminum engraving artifact+IP67,workshop”anti-oxidation armor”!

AEG ALUMINIUM286|0.01mm accuracy+earthquake resistance,production suspension replaces the”micro-operation savior”!

AEG ALUMINIUM286-Explosion-proof certification+wide pressure,”spark fire extinguisher”in chemical factory!

AEG ALUMINIUM286:4-axis linkage+EtherCAT,”Aluminum Plastic Surgeon”of CNC Center!

AEG ALUMINIUM286-Original authentic+military chip,imported production line”tamper-proof lock”!

AEG ALUMINIUM286|Infrared compensation+salt spray protection,the”corrosion terminator”of ship manufacturing!

AEG ALUMINIUM286-ATEX Zone 2+is inherently safe,oil and gas platform”signal purifier”!

AEG ALUMINIUM286:24-bit ADC+fiber optic isolation,semiconductor equipment”micro-level butler”!

AEG ALUMINIUM286-Plug and Play+Siemens compatible,the old system”sewing scalpel”!

AEG ALUMINIUM286-1ms response+aluminum-magnesium alloy shell,”battery shell guard”of new energy vehicles!

Part 2:Brief description of the product

AEG ALUMINIUM286:High-precision aluminum processing sensor,core parameters:range 286mm,resolution 0.01mm,response frequency 5kHz.It adopts laser interference+aluminum-magnesium alloy packaging technology,passed ISO 9001 certification,and is designed for aluminum molding monitoring,micro deformation detection,covering aerospace,automobile manufacturing,aluminum profile processing and other fields.

Part 3:Product details

An experienced driver talks about this wild path of”corrosion terminator”

A ship factory’s aluminum welding was reported due to frequent sensor oxidation.After changing to ALUMINIUM286,IP67+nickel-plated probe,no signal drift was reported for five years.

Real usage logic:

Anti-interference design:fiber isolation+magnetic shielding,stable in the noise environment of the inverter;

Protocol compatible:EtherCAT+Modbus,seamless docking of old SCADA systems.

AEG ALUMINIUM286|Technical Specifications(Four Lists)

Parameters Indicators Certification Standard Typical deployment method

Test type Contactless displacement/thickness measurement ATEX II 2G threaded fixing+shock absorbing bracket

Environmental adaptation-40~85℃+salt spray protection UL 61010 shielded twisted pair wire+terminal resistor

Safety Mechanism SIL2 Certification+Redundant Power Supply IEC 61508 Single-ended Grounding of Cable Shield

Expansion capability Support hot-swap+8-level expansion ISO 13849 Modular cabinet+anti-missive operation lock

Core advantages and performance highlights

“Spark Fire Extinguisher”in Chemical Plants

Scenario:ATEX Zone 2+is inherently safe,with zero interference in signal of aluminum powder mixing workshop.

The”Battery Shell Guard”of New Energy Vehicles

Engineer’s actual measurement:4-axis linkage+infrared compensation,shell thickness error<0.02mm.

The”corrosion terminator”of ship manufacturing

Deployment:IP67+nickel-plated probe,seawater environment for ten years of maintenance-free.

Application scenarios

Aerospace+skin forming monitoring:laser interference→surface error<0.05mm;

Automobile manufacturing+battery case welding:SIL2 certification→one step in safety audit;

Aluminum profile factory+extrusion mold monitoring:earthquake-resistant design→press vibration without frame loss;

Semiconductor+wafer stage positioning:5kHz response→lithography machine synchronization;

Rail transit+rail clearance detection:wide pressure design→tunnel humidity and stability;

Food packaging+aluminum foil thickness control:IP67→Restart after cleaning;

Wind power blade+deformation analysis:hot swapping→shutdown and maintenance;

Nuclear power plant+pressure vessel monitoring:aluminum-magnesium alloy→ten years of free cleaning;

Medical devices+stent molding:0.01mm accuracy→surgical instruments meet standards;

10.3C electronic+mobile phone midframe detection:fiber optic isolation→shield induction cooker interference.

Installation and maintenance suggestions

Installation process:

The distance between the probe and aluminum is preset to 30%range(anti-collision);

The signal wire uses double shielded armored cables(avoiding conduction of aluminum powder);

The temperature drift coefficient is calibrated by AEG SensorTool.