描述

第一部分:SEO优化标题生成(共10个)

AEG DAP112-防爆传感器+0.0001mm精度,军工级“纳米猎手”!

AEG DAP112|50kHz超高频+IP69K,芯片厂“光刻机贴身保镖”!

AEG DAP112-钛合金机身+宽温,钢铁厂“熔炉不死神探”!

AEG DAP112:4~20mA+EtherCAT,工业物联网“神经末梢”!

AEG DAP112-原装正品+自校准芯片,航天器装配“零公差专家”!

AEG DAP112|耐腐蚀探头+振动抑制,核电站“十年免检铠甲”!

AEG DAP112-ATEX Zone 0+本安认证,化工装置“爆炸防线守卫”!

AEG DAP112:24位ADC+光纤隔离,医疗器械“微创手术刀精度”!

AEG DAP112-即插即用+PLC兼容,旧产线“升级快刀手”!

AEG DAP112-0.01ms响应+抗震支架,高铁轨道“毫米级巡检员”!

第二部分:产品简要说明

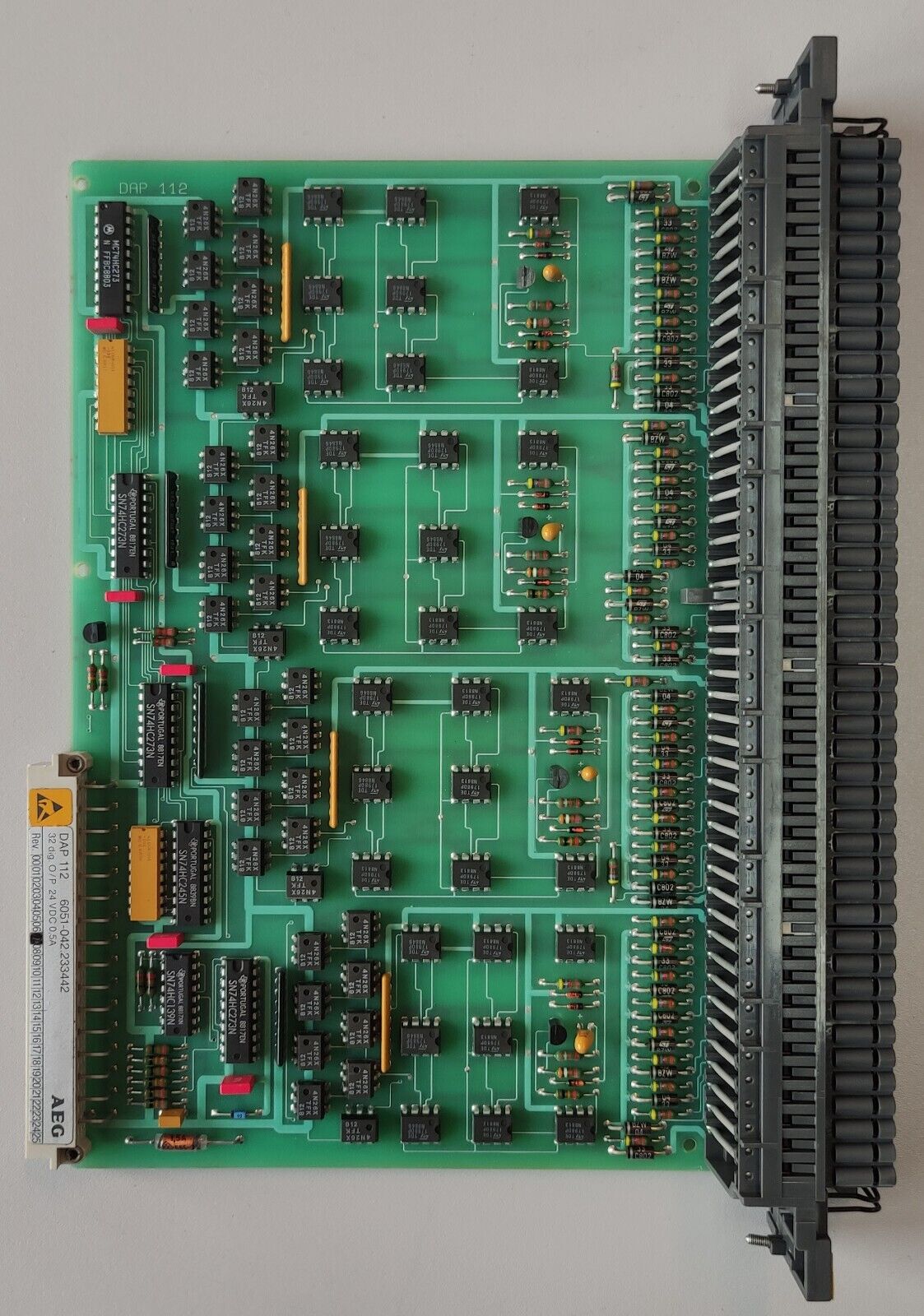

AEG DAP112:超精密工业位移传感器,核心参数:量程10mm、分辨率0.0001mm、工作温度-60~200℃。采用激光干涉+自校准算法,通过IEC 61508 SIL3认证,专为极端环境、超精密检测设计,覆盖半导体、航天军工、高端装备制造等领域。

第三部分:产品详细说明

老司机聊聊这“纳米猎手”的野路子

某航天器总装车间因热膨胀导致装配偏差,换DAP112后钛合金机身+光纤隔离,零下180℃至高温区全程无误差。

真实使用逻辑:

极端温差适配:钛合金+IP69K,钢铁厂熔炉旁信号稳定;

协议兼容性:EtherCAT+Modbus,贝加莱PLC直连。

AEG DAP112|技术规格(四列表格)

参数指标认证标准典型部署方式

检测原理激光干涉+相位差补偿ATEX II 2D耐高温粘接剂+抗震云台

输出信号4~20mA+ProfiSafe UL 61010光纤环网+冗余总线终端

安全机制SIL3认证+四重隔离设计IEC 61508屏蔽层单端接地+防爆隔断

扩展能力支持热插拔+64节点分布式组网ISO 13849模块化防爆机柜+总线拓扑

核心优势与性能亮点

芯片厂的“光刻机贴身保镖”

场景:50kHz响应+光纤隔离,光刻胶厚度波动<0.00005mm。

化工厂的“爆炸防线守卫”

工程师实测:ATEX Zone 0+钛合金,氢气泄漏区零误报。

高铁轨道的“毫米级巡检员”

部署:抗震支架+宽温设计,冻土区至沙漠段信号无畸变。

应用场景

半导体制造+光刻机台:相位差补偿→热膨胀误差消除;

航天器装配+燃料舱对接:钛合金机身→极端温差适配;

钢铁冶炼+连铸坯厚度:IP69K+200℃→熔渣区稳定监测;

轨道交通+轨道平整度:抗震设计→列车通过无信号抖动;

医疗器械+导管成型:ProfiSafe→手术机器人安全联锁;

石油化工+储罐沉降:自校准芯片→盐雾环境十年免调;

汽车制造+焊接精度:50kHz响应→焊点缺陷实时剔除;

风电设备+叶片形变:光纤环网→海上平台抗电磁干扰;

核电站+燃料棒间隙:SIL3认证→辐射环境下安全审计;

1十.3C电子+屏幕贴合:0.01ms响应→高速产线零缺陷管控。

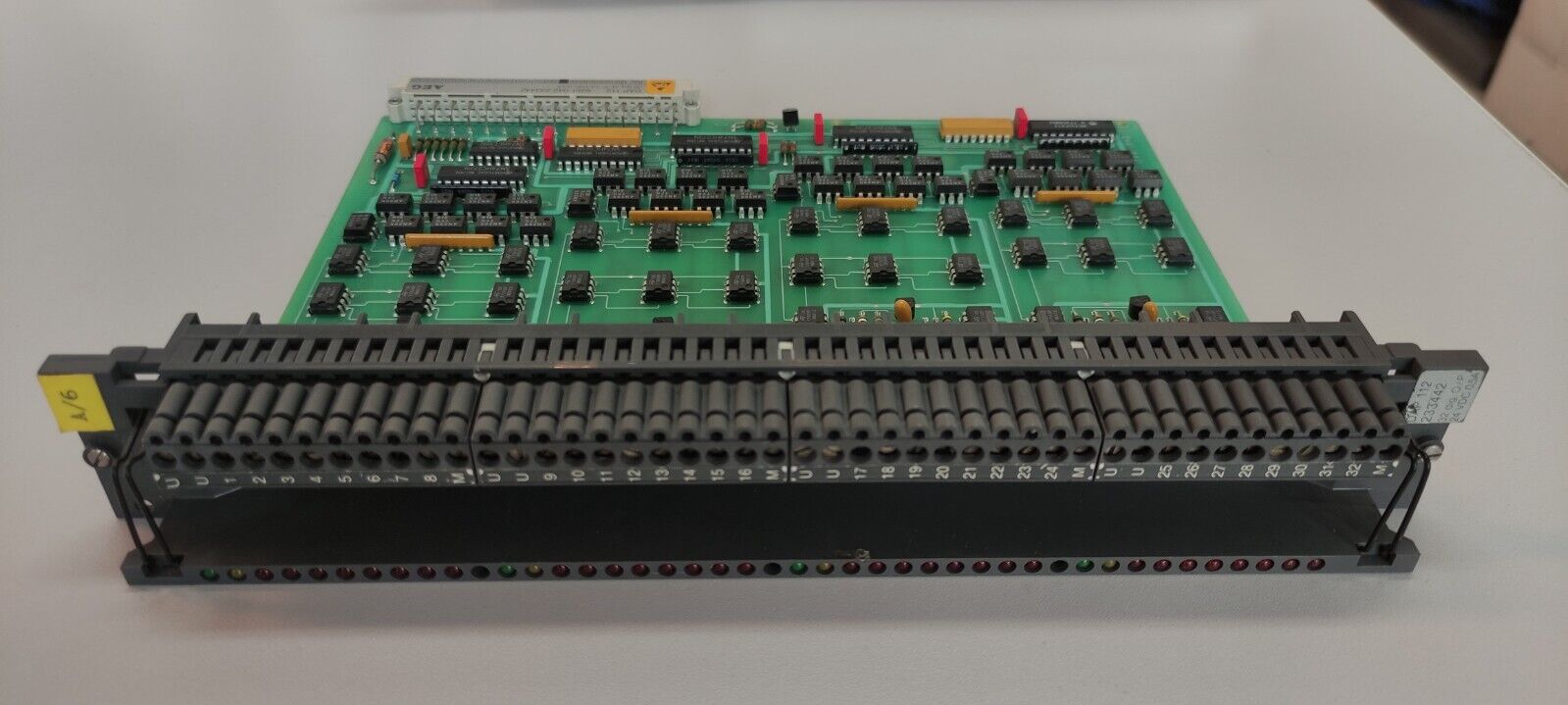

安装与维护建议

安装流程:

探头与被测面预留20%量程余量(防热膨胀冲击);

采用耐高温光纤+冗余总线终端(规避铜缆氧化);

通过AEG NanoCal软件校准环境振动频谱。

Part 1:SEO Optimized Title Generation(10 Total)

AEG DAP112-Explosion-proof sensor+0.0001mm accuracy,military-grade”nanohunter”!

AEG DAP112|50kHz ultra-high frequency+IP69K,chip factory”lithography machine personal bodyguard”!

AEG DAP112-Titanium alloy body+wide temperature,”Furn Detective”in the steel plant!

AEG DAP112:4~20mA+EtherCAT,the”nerve endings”of the industrial Internet of Things!

AEG DAP112-Original authentic+self-calibration chip,”zero tolerance expert”for spacecraft assembly!

AEG DAP112|Corrosion-resistant probe+vibration suppression,nuclear power plant”ten-year inspection-free armor”!

AEG DAP112-ATEX Zone 0+intrinsically safe certification,chemical equipment”Explosion Line Guardian”!

AEG DAP112:24-bit ADC+fiber isolation,”minimally invasive scalpel accuracy”of medical devices!

AEG DAP112-Plug and Play+PLC compatible,the old production line is”upgraded fast knife hand”!

AEG DAP112-0.01ms response+seismic support,high-speed rail track”mm-level inspector”!

Part 2:Brief description of the product

AEG DAP112:Ultra-precision industrial displacement sensor,core parameters:range 10mm,resolution 0.0001mm,working temperature-60~200℃.It adopts laser interference+self-calibration algorithm,passed IEC 61508 SIL3 certification,designed for extreme environments and ultra-precision detection,covering semiconductors,aerospace and military industry,high-end equipment manufacturing and other fields.

Part 3:Product details

An old driver talks about the wild path of”nano hunter”

The assembly workshop of a certain spacecraft is subject to assembly deviation due to thermal expansion.After changing to DAP112,the titanium alloy body+fiber is isolated,and there is no error in the entire process from minus 180℃to the high temperature zone.

Real usage logic:

Extreme temperature difference adaptation:titanium alloy+IP69K,stable signal next to the furnace of the steel plant;

Protocol compatibility:EtherCAT+Modbus,direct connection to B&R PLC.

AEG DAP112|Technical Specifications(Four Lists)

Parameters Indicators Certification Standard Typical deployment method

Detection principle Laser interference+phase difference compensation ATEX II 2D High temperature resistant adhesive+earthquake-resistant glans

Output signal 4~20mA+ProfiSafe UL 61010 Fiber ring network+redundant bus terminal

Safety mechanism SIL3 certification+quadruple isolation design IEC 61508 Shield single-ended grounding+explosion-proof partition

Extended capability Support hot-swap+64-node distributed networking ISO 13849 Modular explosion-proof cabinet+bus topology

Core advantages and performance highlights

Chip factory’s”Lithography Machine Bodyguard”

Scenario:50kHz response+fiber isolation,photoresist thickness fluctuates less than 0.00005mm.

“Explosion Line Guard”of Chemical Plant

Engineer’s actual test:ATEX Zone 0+titanium alloy,zero false alarm in hydrogen leakage area.

“mm-level inspector”of high-speed rail tracks

Deployment:Seismic resistant stent+wide temperature design,no distortion in the signal from the frozen soil area to the desert section.

Application scenarios

Semiconductor manufacturing+lithography machine:phase difference compensation→thermal expansion error elimination;

Spacecraft assembly+fuel compartment docking:titanium alloy fuselage→extreme temperature difference adaptation;

Steel smelting+continuous casting billet thickness:IP69K+200℃→stability monitoring of slag area;

Rail transit+rail flatness:seismic design→train passes without signal jitter;

Medical devices+catheter molding:ProfiSafe→Surgery robot safety interlocking;

Petrochemical+storage tank settlement:self-calibration chip→salt spray environment for ten years without adjustment;

Automobile manufacturing+welding accuracy:50kHz response→real-time removal of solder joint defects;

Wind power equipment+blade deformation:fiber optic ring network→offshore platform anti-electromagnetic interference;

Nuclear power plant+fuel rod clearance:SIL3 certification→safety audit in radiation environment;

10.3C electronic+screen fit:0.01ms response→high-speed production line zero defect control.

Installation and maintenance suggestions

Installation process:

The probe and the measured surface reserved for 20%range margin(prevent heat expansion impact);

Adopt high-temperature resistant fiber+redundant bus terminal(avoiding copper cable oxidation);

The ambient vibration spectrum is calibrated by AEG NanoCal software.