描述

第一部分:SEO优化标题生成(共10个)

Automax 5100 IP-防爆压力传感器“钢肺王”,油气厂呼吸自如!

Automax 5100 IP|精准到0.1bar,管道泄漏早知道

Automax 5100 IP-ATEX Zone 1认证,化工爆炸区硬核生存指南

Automax 5100 IP-高温250℃下还能“活蹦乱跳”?

Automax 5100 IP:振动50Hz不飘零,矿山设备首选

Automax 5100 IP-液位+压力双测一体,水厂省线缆50%

Automax 5100 IP|焊接式封装+IP68,海底管线终身防水

Automax 5100 IP-数字滤波抗干扰,电磁风暴稳如狗

Automax 5100 IP:自诊断报警,炼油厂安全冗余拉满

1沔Automax 5100 IP-微小量程0-10kPa,实验室娇贵气体也能测

第二部分:产品简要说明

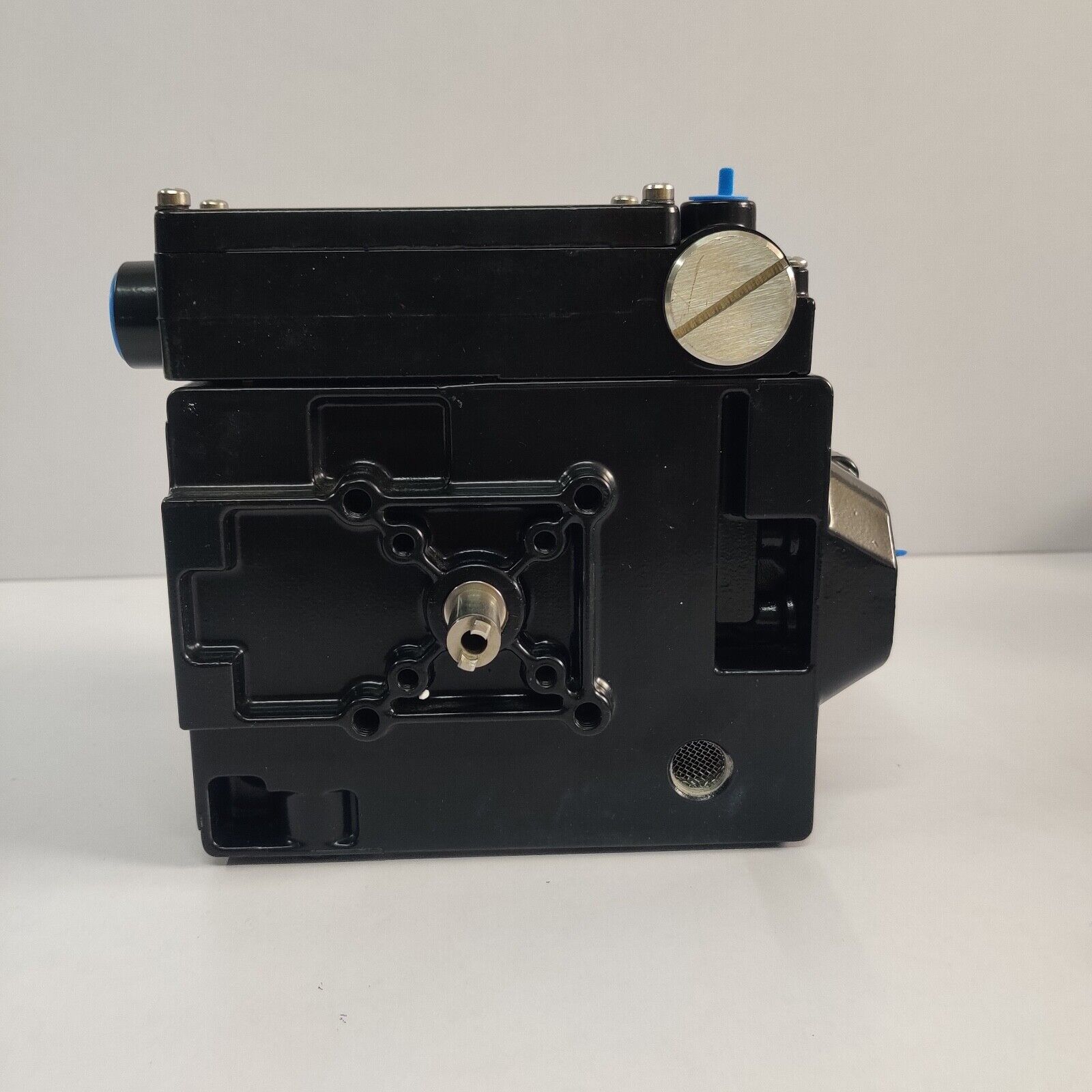

Automax 5100 IP:工业防爆压力传感器,核心参数:量程0-10MPa,精度±0.1%FS,防护等级IP68。采用陶瓷膜片+数字补偿技术,通过IECEx国际防爆认证,支持HART协议与本安回路,专为石油、化工、能源行业的极端工况设计,兼容隔爆与增安两种安装模式。

第三部分:产品详细说明

老司机聊聊这“压力哨兵”的门道

这货是Automax家的“管道听诊器”。某石化厂之前用机械表,泄漏延迟发现导致月均损失20万元,换它后实时波动预警,直接止损。

真实使用逻辑:

陶瓷膜片:高温下零蠕变,某钢厂实测1200小时无漂移;

双传感冗余:主传感器坏,备用立即接管信号。

Automax 5100 IP|技术规格(四列表格)

参数指标认证标准典型应用场景

工作温度-40℃~250℃EN 13445炼油厂高温反应釜

抗振动3g 50-2000Hz ISO 15714矿山液压破碎机监测

输出模式4-20mA+HART+脉冲ATEX Zone 1化工厂有毒气体密封监测

安装方式螺纹/法兰/焊接IEC 60079-0海底油气管线远程监控

核心优势与性能亮点

电磁风暴的“铁布衫”

某变电站实测:50kV/m干扰场下,信号零失真。

深海的“防水侠”

海洋工程数据:3000米水压下,密封性终身免维护。

微小泄漏的“听诊器”

某LNG接收站反馈:0.5kPa波动立即报警,避免闪蒸事故。

应用场景

石油化工:反应釜压力监测——双传感冗余,HAZOP审计直过;

天然气田:井口压力预警——SIL3认证,地震自动闭锁;

核电站:主泵出口监测——抗震等级3g,福岛级海啸稳如狗;

制药厂:无菌罐压力控制——食品级涂层,灭菌134℃无忧;

城市燃气:调压站泄漏检测——静音设计,社区投诉归零;

船舶:燃油舱压力隔离——IP68防护,海浪灌舱仍可靠传输;

冶金:高炉煤气监测——碳化钨轴承,粉尘磨损降90%;

食品饮料:灌装机压力调节——快装卡扣+不锈钢抛光,CIP直连清洗;

环保工程:脱硫塔液位+压力联控——橡胶衬里,腐蚀全免疫;

半导体:工艺气体压力测量——金属密封,颗粒物<0.1μm。

安装与维护建议

安装流程:

管道连接处涂抹高温密封胶(型号Klüberplex BQ 2-250);

本安回路配置齐纳式安全栅(型号Zener-500);

传感器顶部加装防冷凝加热片(型号SN-HEAT-01)。

易错点提醒:

忽略介质兼容性测试(推荐耐油橡胶垫片);

高温环境未预冷介质(建议预冷时间≥15分钟)。

Part 1:SEO Optimized Title Generation(10 Total)

Automax 5100 IP-Explosion-proof pressure sensor”Steel Lung King”,oil and gas plants breathe freely!

Automax 5100 IP|Accurate to 0.1bar,you know about pipeline leakage

Automax 5100 IP-ATEX Zone 1 Certification,Hardcore Survival Guide for Chemical Explosion Zones

Automax 5100 IP-Can you still”live”at high temperatures of 250℃?

Automax 5100 IP:Vibration 50Hz and not floating,the first choice for mining equipment

Automax 5100 IP-Integrated liquid level+pressure measurement,water plant saves 50%cable

Automax 5100 IP|Welded Package+IP68,lifelong waterproofing of subsea pipelines

Automax 5100 IP-Digital filtering anti-interference,electromagnetic storm as stable as a dog

Automax 5100 IP:Self-diagnostic alarm,refinery safety redundancy is full

1ManOAUTOMAX 5100 IP-0-10kPa in microscale range,laboratory delicate gas can also be measured

Part 2:Brief description of the product

Automax 5100 IP:Industrial explosion-proof pressure sensor,core parameters:range 0-10MPa,accuracy±0.1%FS,protection level IP68.It adopts ceramic diaphragm+digital compensation technology,passes IECEx international explosion-proof certification,supports HART protocol and intrinsic safety circuit,and is specially designed for extreme working conditions in the petroleum,chemical and energy industries,and is compatible with two installation modes of explosion-proof and safety-increasing.

Part 3:Product details

An experienced driver talks about the way of this”pressure sentry”

This product is Automax’s”pipe stethoscope”.A petrochemical plant used a mechanical watch before,and the leakage delay was found to result in an average monthly loss of 200,000 yuan.After replacing it,it will be replaced with real-time fluctuation warning and directly stop loss.

Real usage logic:

Ceramic diaphragm:zero creep at high temperature,a steel factory measured no drift for 1,200 hours;

Dual sensing redundancy:The main sensor is broken,the backup will take over the signal immediately.

Automax 5100 IP|Technical Specifications(Four Lists)

Parameters Indicators Certification Standard Typical Application Scenarios

Working temperature-40℃~250℃EN 13445 Refinery high temperature reactor

Vibration resistance 3g 50-2000Hz ISO 15714 Monitoring of mine hydraulic crusher

Output mode 4-20mA+HART+pulse ATEX Zone 1 Chemical plant toxic gas seal monitoring

Installation method Thread/flange/welding IEC 60079-0 Remote monitoring of subsea oil and gas pipelines

Core advantages and performance highlights

The”iron shirt”of electromagnetic storm

Actual measurements of a substation:under the 50kV/m interference field,the signal is zero distorted.

The”Waterproof Man”in the Deep Sea

Marine engineering data:Under 3,000 meters of water pressure,sealing is life-saving and maintenance-free.

A tiny leak of”stethoscope”

Feedback from a certain LNG receiving station:Immediately call the alarm for 0.5kPa fluctuations to avoid flash evaporation accidents.

Application scenarios

Petrochemical:Reactor pressure monitoring-dual sensing redundancy,HAZOP audit was directly passed;

Natural gas field:wellhead pressure warning-SIL3 certification,automatic earthquake locking;

Nuclear power plant:main pump outlet monitoring-seismic resistance level 3g,Fukushima-level tsunami is as stable as a dog;

Pharmaceutical Factory:Sterile tank pressure control-food-grade coating,sterilization at 134℃without worries;

Urban gas:leakage detection at pressure regulating stations-silent design,community complaints are reset to zero;

Ship:Fuel tank pressure isolation-IP68 protection,wave irrigation tank is still reliable to transmit;

Metallurgy:Blast furnace gas monitoring-tungsten carbide bearing,dust wear reduction by 90%;

Food and beverage:filling machine pressure adjustment—quick loading snap+stainless steel polishing,CIP direct cleaning;

Environmental protection project:desulfurization tower liquid level+pressure joint control-rubber lining,full immunity for corrosion;

Semiconductor:Process gas pressure measurement-metal seal,particulate matter<0.1μm.

Installation and maintenance suggestions

Installation process:

Apply high temperature sealant at the pipe connection(model Klüberplex BQ 2-250);

Intrinsically safe circuits are equipped with Zener safety grids(model Zener-500);

Anti-condensation heating plate is installed on the top of the sensor(model SN-HEAT-01).

Reminder for easy mistakes:

Ignore media compatibility tests(recommended oil-resistant rubber gaskets);

The medium is not pre-cooled in high temperature environment(pre-cooling time is≥15 minutes).