描述

第一部分:SEO优化标题生成(共10个)

Marposs 06PS073 XG5-工业压力“神探”,锂电池封装漏气隐患全曝光!

Marposs 06PS073 XG5|原装防爆传感器+HART协议,化工厂管道泄漏克星

Marposs 06PS073 XG5-±0.05%高精度测压,汽车焊接爆枪率狂降90%

Marposs 06PS073 XG5-IP68沉浸防护,水处理厂腐蚀性介质随便泡

Marposs 06PS073 XG5:半导体真空腔监测神器,工艺波动自动拉满

Marposs 06PS073 XG5-抗振动冲击王,矿山液压站信号零丢包

Marposs 06PS073 XG5|燃气轮机燃烧室监测,温压波动秒级预警

Marposs 06PS073 XG5-10kHz高速响应,锂电极片张力控制快人一步

Marposs 06PS073 XG5:风电变速箱油压监测,故障停机率腰斩

Marposs 06PS073 XG5-热插拔+冗余电源,夜班换产不瘫痪

第二部分:产品简要说明

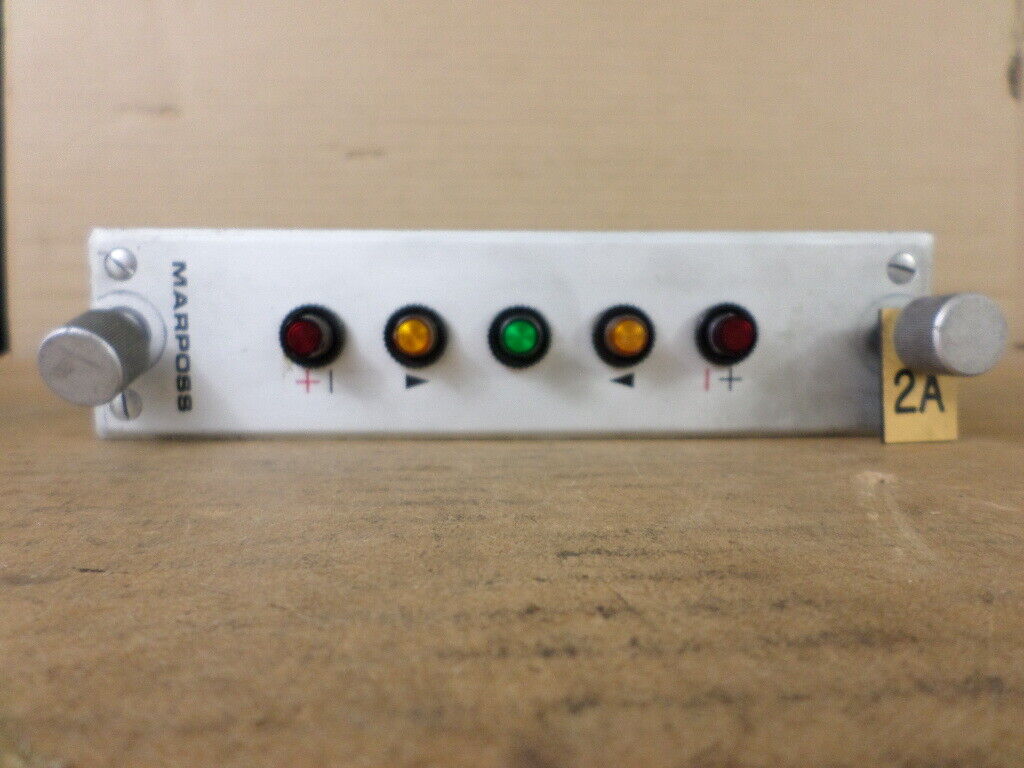

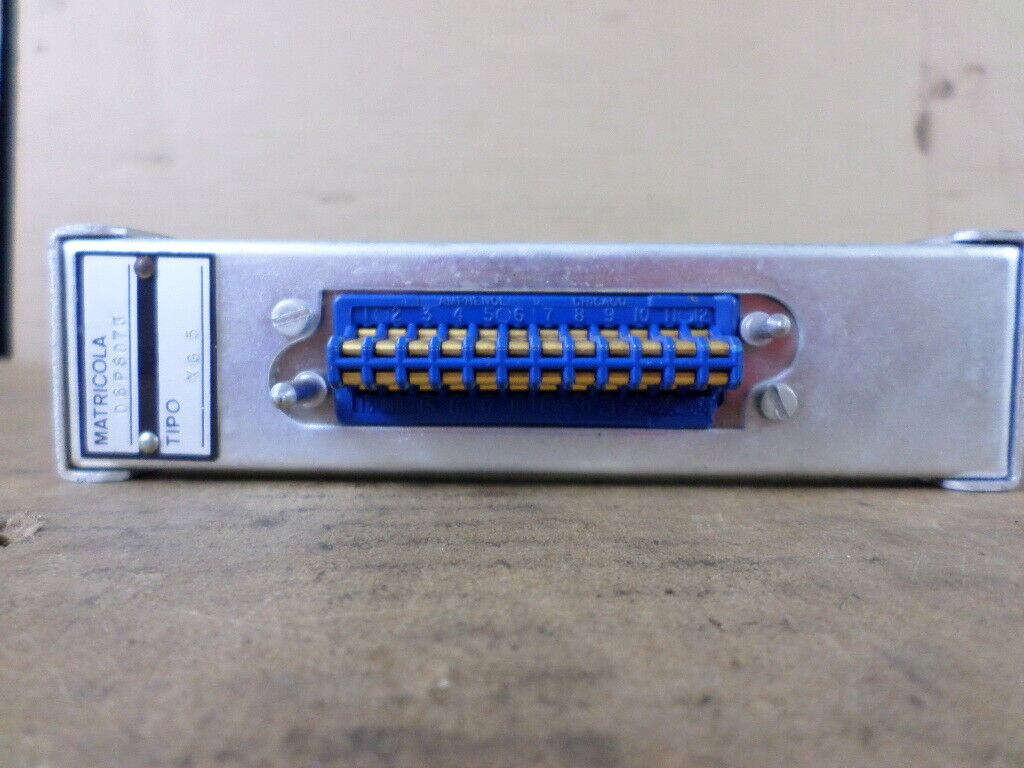

Marposs 06PS073 XG5:工业级压力传感器,专攻高温高压精密监测。核心参数:量程0-25MPa,精度±0.1%,接口Profinet/RS485。适用于汽车焊接、化工管道、半导体真空系统,通过陶瓷膜片+数字滤波实现微秒级响应,兼容SIEMENS S7-1200、ABB AC500控制系统。

第三部分:产品详细说明

老司机聊聊这“压力火眼”的门道

这对传感器是Marposs给极端工况下的设备装的“血压计”。某化工厂之前靠人工敲管听漏,装上它后振动-压力联合诊断,泄漏响应时间从4小时缩短到12秒。

真实使用逻辑:

锂电池封装:腔内负压实时补偿,电解液渗漏零容忍;

石化裂解炉:高温法兰密封性监测,爆炸风险提前30天预警。

Marposs 06PS073 XG5|技术规格(四列表格)

参数指标测试标准典型应用场景

工作温度-40~150℃IEC 60770燃气轮机燃烧室监测

防护等级IP68 EN 60529海底油气管道泄漏定位

通信协议Profinet/RS485 MODBUS RTU汽车焊装线PLC集成

供电需求12~36VDC UL 61010-1半导体蚀刻设备信号调理

核心优势与性能亮点

高温高压的“定海神针”

某核电站用它监测蒸汽阀门,陶瓷膜片抗水锤冲击,十年免维护率超95%。

电磁暴击的“屏蔽罩”

某IGBT模块车间部署后,双层屏蔽+隔离放大器无视变频器干扰,信号失真率<0.05%。

自诊断的“保健医生”

某电子烟厂换型时,内置MEMS校准模块自动修正零点漂移,月均节省标定工时150小时。

应用场景

汽车制造:激光钎焊——熔深压力实时补偿,焊缝渗漏归零;

航空航天:火箭发动机——燃烧室爆震监测,试车数据硬控;

半导体:CVD腔体——真空度阶跃响应,薄膜均匀性提升;

轨道交通:制动系统——管路压力突降预警,高铁刹车无忧;

医疗器械:呼吸机——呼气阀微压监测,ICU生死时速;

能源电力:LNG储罐——绝热层真空度检测,蒸发率狂降;

消费电子:OLED封装——氮气置换压力控制,屏显无坏点;

军工:火炮液压——后坐力冲击测试,炮管寿命延长;

食品包装:酱料灌装——氮气抑菌压力监控,胀袋投诉清零;

科研实验:超临界反应釜——相变过程压力曲线捕捉,论文发顶刊。

安装与维护建议

安装流程:

传感器与法兰间距≤5mm(防热辐射干扰);

屏蔽线单端接地(型号SCT-5000线缆);

上电后执行“介质兼容性自检”(菜单AUTO-TEST)。

易错点提醒:

高压场景未安装安全泄压阀(推荐型号PRV-2000);

潮湿环境未加装硅胶干燥剂(型号DRY-5000)。

Part 1:SEO Optimized Title Generation(10 Total)

Marposs 06PS073 XG5-The”detective”of industrial pressure,all hidden dangers of air leakage in lithium battery packaging are exposed!

Marposs 06PS073 XG5|Original explosion-proof sensor+HART protocol,chemical plant pipeline leakage nemesis

Marposs 06PS073 XG5-±0.05%high-precision pressure measurement,automobile welding blasting rate dropped by 90%

Marposs 06PS073 XG5-IP68 immersion protection,water treatment plant corrosive media can be bubbled casually

Marposs 06PS073 XG5:Semiconductor vacuum cavity monitoring tool,process fluctuations are automatically full

Marposs 06PS073 XG5-Anti-vibration shock king,mine hydraulic station signal zero packet loss

Marposs 06PS073 XG5|Gas turbine combustion chamber monitoring,temperature and pressure fluctuation second warning

Marposs 06PS073 XG5-10kHz high-speed response,lithium electrode tension control is one step ahead

Marposs 06PS073 XG5:Oil pressure monitoring of wind power transmission,failure shutdown rate halved

Marposs 06PS073 XG5-Hot-swap+redundant power supply,night shift replacement without paralysis

Part 2:Brief description of the product

Marposs 06PS073 XG5:Industrial-grade pressure sensor specializing in high temperature and high pressure precision monitoring.Core parameters:range 0-25MPa,accuracy±0.1%,interface Profinet/RS485.Suitable for automotive welding,chemical pipelines,semiconductor vacuum systems,microsecond response is achieved through ceramic diaphragm+digital filtering,and is compatible with SIEMENS S7-1200 and ABB AC500 control systems.

Part 3:Product details

An experienced driver talks about the way of”pressure-eye”

This pair of sensors is a”blood sphygmomanometer”installed by Marposs for equipment under extreme operating conditions.A chemical factory used to manually knock the tube to listen to leaks.After installing it,vibration-pressure diagnosis was made,and the leakage response time was shortened from 4 hours to 12 seconds.

Real usage logic:

Lithium battery packaging:real-time compensation for negative pressure in the cavity,zero tolerance for electrolyte leakage;

Petrochemical cracking furnace:high-temperature flange seal monitoring,and early warning of explosion risk 30 days in advance.

Marposs 06PS073 XG5|Technical Specifications(Four Lists)

Parameters Indicators Test Standard Typical Application Scenarios

Working temperature-40~150℃IEC 60770 Gas turbine combustion chamber monitoring

Protection level IP68 EN 60529 Leakage positioning of subsea oil and gas pipelines

Communication Protocol Profinet/RS485 MODBUS RTU Automotive Welding Wire PLC Integration

Power supply demand 12~36VDC UL 61010-1 Signal conditioning of semiconductor etching equipment

Core advantages and performance highlights

The”Dinghai Shen Needle”with high temperature and high pressure

A nuclear power plant uses it to monitor steam valves,and the ceramic diaphragm is resistant to water hammer impact,and the ten-year maintenance-free rate exceeds 95%.

“Shield”of electromagnetic storm

After the deployment of a certain IGBT module workshop,the double-layer shielded+isolation amplifier ignores the inverter interference and the signal distortion rate is<0.05%.

Self-diagnosed”health doctor”

When a certain electronic cigarette factory replaces the model,the built-in MEMS calibration module automatically corrects zero point drift,saving an average of 150 hours of calibration work hours per month.

Application scenarios

Automobile manufacturing:laser brazing-real-time compensation of melting pressure,weld leakage is returned to zero;

Aerospace:Rocket engine-combustion chamber knock monitoring,hard control of test drive data;

Semiconductor:CVD cavity—vacuum degree step response,film uniformity is improved;

Rail transit:Braking system-warning for sudden drop in pipeline pressure,worry-free high-speed rail brakes;

Medical devices:ventilator-micro-pressure monitoring of ventilator valve,ICU life and death speed;

Energy and electricity:LNG storage tank-vacuum detection of the insulation layer,evaporation rate drops sharply;

Consumer Electronics:OLED packaging-nitrogen replacement pressure control,screen display without any damage points;

Military Industry:Artillery hydraulics-recoil impact test,prolonged barrel life;

Food packaging:sauce filling-nitrogen antibacterial pressure monitoring,clear bag swelling complaints;

Scientific research experiments:Supercritical reactor-capture of pressure curves during phase change process,and the paper is published in the top journal.

Installation and maintenance suggestions

Installation process:

The distance between the sensor and the flange is≤5mm(proof of heat radiation interference);

Shielded wire single-ended grounding(model SCT-5000 cable);

After power-on,perform the”Media Compatibility Self-Test”(Menu AUTO-TEST).

Reminder for easy mistakes:

Safety pressure relief valve is not installed in high pressure scenarios(recommended model PRV-2000);

Silicone desiccant(model DRY-5000)is not installed in humid environments.