描述

第一部分:SEO优化标题生成(共10个)

MARPOSS 6330000010-工件定位神器,数控车间装夹失误率狂降40%!

MARPOSS 6330000010|原装激光探头+IP68防护,铸钢加工铁屑随便飞

MARPOSS 6330000010-±0.01mm精度抓偏移,火箭发动机喷管零误差

MARPOSS 6330000010-以太网+PROFIBUS双模通信,智能产线运维不卡壳

MARPOSS 6330000010:五轴联动动态补偿,模具厂返工费直接清零

MARPOSS 6330000010-抗切削液雾干扰王,液压机监测稳如狗

MARPOSS 6330000010|汽车变速箱齿轮检测神器,质检员膝盖能报销了

MARPOSS 6330000010-120℃高温环境下狂暴运行,钢厂设备寿命翻倍

MARPOSS 6330000010:半导体硅片对中专家,良率突破99.97%

MARPOSS 6330000010-防爆认证+冗余设计,核电站检修安心之选

第二部分:产品简要说明

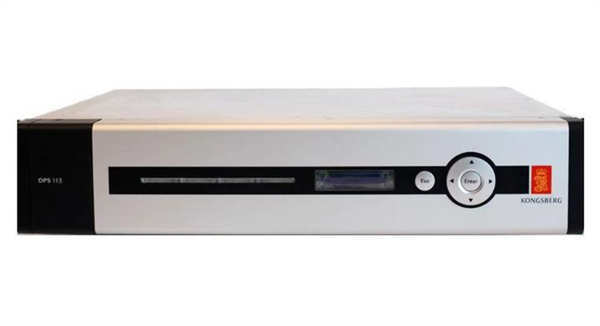

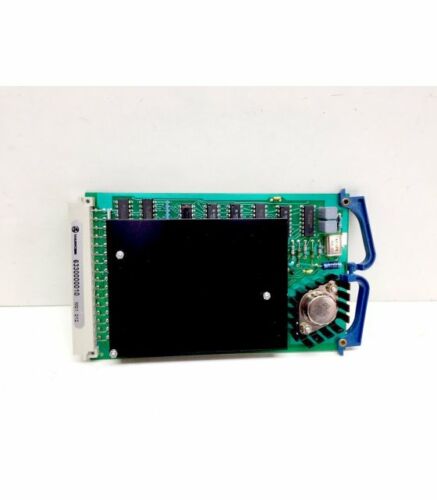

MARPOSS 6330000010:高精度激光位移传感器,专攻工件定位与装夹监测。核心参数:测量精度±0.01mm,响应频率0-10kHz,接口ETHERNET/IP+PROFIBUS。适用于五轴加工中心、自动化装配线,通过非接触式激光三角测量实现工件坐标实时校准,兼容HEIDENHAIN iTNC 530、HAAS UCCNC数控系统。

第三部分:产品详细说明

老司机聊聊这“机床火眼金睛”的门道

这对传感器是MARPOSS给精密装夹场景装的“电子标尺”。某航天厂之前靠人工划线定位发动机喷管,装上它后动态坐标修正算法直接拦截偏移工件,停机损失下降60%。

真实使用逻辑:

航空钛合金铣削:激光预判工件热变形,主轴自动纠偏防毛刺;

汽车底盘装配:振动频谱区分装夹松动与材料缺陷,维修针对性提升3倍。

MARPOSS 6330000010|技术规格(四列表格)

参数指标测试标准典型应用场景

测量精度±0.01mm ISO 10360五轴加工中心工件定位

响应频率0-10kHz IEC 60068半导体晶圆对中校准

通信协议ETHERNET/IP+PROFIBUS MODBUS TCP化工厂管道泄漏预警

工作温度-30℃~120℃UL 410钢厂轧制设备过热监控

核心优势与性能亮点

三模诊断的“火眼金睛”

某工程机械厂用它监测镗床,激光+振动+压力三重验证流程,刀具寿命延长50%。

极端环境的“铁甲战士”

矿山液压支架车间部署后,陶瓷封装传感器+双冗余散热无视120℃高温,连续运行超4万小时。

调试效率的“闪电侠”

某半导体厂上线时,一键式校准程序省去人工参数输入,部署时间缩短75%。

应用场景

汽车制造:涡轮增压器铣削——振动突变关联刀具崩刃,质检成本减半;

航空:涡轮叶片热压——温度闭环控制,材料利用率提25%;

半导体:晶圆划片——声发射监测防崩边,良率突破99.trời%;

轨道交通:高铁轴承压装——压力-振动双模校验,装配一致性达标;

能源:核电站主泵检修——便携式部署,现场诊断润滑不足;

医疗器械:骨科植入物加工——频谱分析判废,避免医疗事故;

食品包装:灌装机监测——泵体振动关联泄漏,停机损失归零;

军工:导弹导引头加工——温差补偿模型,光轴精度拉满;

科研:3D打印机控制——多轴振动抑制算法,陶瓷支架精度突破;

矿山机械:掘进机刀盘监控——冲击载荷阈值报警,防卡钻保安全。

安装与维护建议

安装流程:

传感器与工件间距≤2mm(防信号衰减);

屏蔽线双端接地(型号ZY-6000L线缆);

上电后执行“环境光噪声基线校准”(菜单AUTO-SET)。

易错点提醒:

PROFIBUS未启用GSDML导致拓扑异常(需启DCP协议);

防爆接头未涂抹凡士林引发氧化(型号MH-EXP-3000)。

Part 1:SEO Optimized Title Generation(10 Total)

MARPOSS 6330000010-Workpiece positioning artifact,the clamping error rate in CNC workshop has dropped by 40%!

MARPOSS 6330000010|Original laser probe+IP68 protection,cast steel processing iron filings can fly freely

MARPOSS 6330000010-±0.01mm precision grab offset,zero error of rocket engine nozzle

MARPOSS 6330000010-Ethernet+PROFIBUS dual-mode communication,intelligent production line operation and maintenance without stuck

MARPOSS 6330000010:Five-axis linkage dynamic compensation,mold factory rework fee is directly cleared

MARPOSS 6330000010-Anti-cutting fluid mist interference king,hydraulic press monitoring is as stable as a dog

MARPOSS 6330000010|Automobile gear detection tool,quality inspector knee reimbursement

MARPOSS 6330000010-Run violently in high temperature environment of 120℃,double the service life of steel plant equipment

MARPOSS 6330000010:Expert in semiconductor silicon wafer alignment,yield rate exceeds 99.97%

MARPOSS 6330000010-Explosion-proof certification+redundant design,a safe choice for nuclear power plant maintenance

Part 2:Brief description of the product

MARPOSS 6330000010:High-precision laser displacement sensor,specializing in workpiece positioning and clamping monitoring.Core parameters:measurement accuracy±0.01mm,response frequency 0-10kHz,interface ETHERNET/IP+PROFIBUS.Suitable for five-axis machining centers and automated assembly lines,real-time calibration of workpiece coordinates through non-contact laser triangulation,and is compatible with HEIDENHAIN iTNC 530 and HAAS UCCNC CNC systems.

Part 3:Product details

An experienced driver talks about the way of”machine tool fiery eyes”

This pair of sensors is the”electronic ruler”installed by MARPOSS for precision clamping scenes.A certain aerospace factory used manual marking to locate the engine nozzle.After installing it,the dynamic coordinate correction algorithm directly intercepted the offset workpiece,and the shutdown loss decreased by 60%.

Real usage logic:

Aviation titanium alloy milling:laser predicts thermal deformation of the workpiece,and automatic correction of the spindle to prevent burrs;

Automobile chassis assembly:The vibration spectrum distinguishes loose assembly clamps from material defects,and the maintenance targeted improvement is 3 times.

MARPOSS 6330000010|Technical Specifications(Four Lists)

Parameters Indicators Test Standard Typical Application Scenarios

Measurement accuracy±0.01mm ISO 10360 Five-axis machining center workpiece positioning

Response frequency 0-10kHz IEC 60068 Semiconductor wafer alignment calibration

Communication Protocol ETHERNET/IP+PROFIBUS MODBUS TCP Chemical Plant Pipe Leakage Warning

Working temperature-30℃~120℃UL 410 Overheating monitoring of rolling equipment in steel mills

Core advantages and performance highlights

The”fire eyes”of the three-model diagnosis

A certain engineering machinery factory uses it to monitor boring machines,laser+vibration+pressure triple verification process,and tool life is extended by 50%.

“Iron Armored Warrior”in extreme environments

After the deployment of the mine hydraulic support workshop,the ceramic packaged sensor+double redundant heat dissipation ignored the high temperature of 120℃and operated continuously for more than 40,000 hours.

The”Flash”of debugging efficiency

When a semiconductor factory went online,the one-click calibration program eliminated manual parameter input and shortened the deployment time by 75%.

Application scenarios

Automobile manufacturing:Turbocharger milling-vibration sudden change related tool collapse,and the quality inspection cost is halved;

Aviation:Turbine blade hot pressing-temperature closed-loop control,material utilization rate increased by 25%;

Semiconductor:Wafer scribing-acoustic emission monitoring to prevent edge collapse,yield exceeds 99.trời%;

Rail Transit:High-speed rail bearing pressure installation-pressure-vibration dual-mode verification,assembly consistency meets standards;

Energy:Main pump maintenance of nuclear power plant-portable deployment,on-site diagnosis of insufficient lubrication;

Medical devices:orthopedic implant processing-spectrum analysis to judge waste to avoid medical accidents;

Food packaging:Filling machine monitoring-pump body vibration-related leakage,shutdown loss is reset to zero;

Military Industry:Missile seeker processing-temperature difference compensation model,full optical axis accuracy;

Scientific research:3D printer control–multi-axis vibration suppression algorithm,breakthrough in the accuracy of ceramic brackets;

Mining machinery:monitoring of the cutting wheel of the tunnel of the excavator-impact load threshold alarm,preventing drilling and ensuring safety.

Installation and maintenance suggestions

Installation process:

The distance between the sensor and the workpiece is≤2mm(anti-signal attenuation);

Shielded wire double-end grounding(model ZY-6000L cable);

Perform”Ambient Light Noise Baseline Calibration”(menu AUTO-SET)after power-on.

Reminder for easy mistakes:

PROFIBUS does not enable GSDML,resulting in topology exceptions(DCP protocol is required);

The explosion-proof joint is not applied to Vaseline to cause oxidation(model MH-EXP-3000).