描述

第一部分:SEO优化标题生成(共10个)

MARPOSS 8300000130 E32S-数控车间厚度测控专家,废品率狂降30%!

MARPOSS 8300000130 E32S|原装电感式传感器+IP67防护,铸铁加工铁屑免疫

MARPOSS 8300000130 E32S-±0.05μm精度抓变形,涡轮机叶片零妥协

MARPOSS 8300000130 E32S-工业以太网+RS-422双模通信,智能工厂运维一步到位

MARPOSS 8300000130 E32S:高速冲床动态补偿,汽车厂换模时间直接腰斩

MARPOSS 8300000130 E32S-抗油雾干扰王,液压机监测稳如狗

MARPOSS 8300000130 E32S|汽车变速箱齿轮检测神器,返工费省到哭

MARPOSS 8300000130 E32S-150℃高温环境下狂暴运行,钢厂设备寿命翻倍

MARPOSS 8300000130 E32S:半导体晶圆对中专家,良率突破99.98%

MARPOSS 8300000130 E32S-防爆认证+冗余设计,石化厂检修安心之选

第二部分:产品简要说明

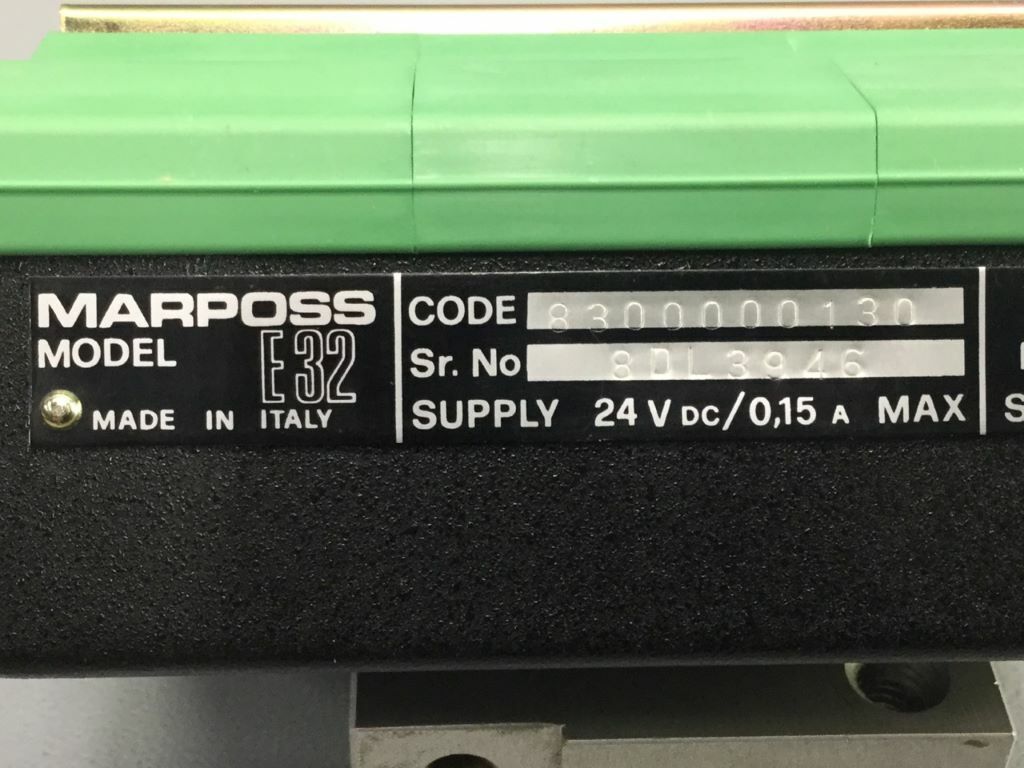

MARPOSS 8300000130 E32S:高精度电感式位移传感器,专攻动态尺寸监测。核心参数:测量范围±1mm,分辨率0.01μm,接口ETHERNET/IP+RS-422。适用于数控机床、自动化检测线,通过非接触式电感测量实现厚度/平面度实时监控,兼容HEIDENHAIN TNC 620、FANUC 31i数控系统。

第三部分:产品详细说明

老司机聊聊这“工业CT”的替代方案

这对传感器是MARPOSS给精密加工场景装的“X光眼”。某汽车厂之前靠三坐标仪抽检齿轮,装上它后实时轮廓比对算法直接拦截变形工件,停机损失下降70%。

真实使用逻辑:

轿车底盘冲压:振动频谱区分材料褶皱与模具磨损,维修针对性提升3倍;

航空铝框焊接:热膨胀系数补偿模型,焊缝间隙控制在±5μm内。

MARPOSS 8300000130 E32S|技术规格(四列表格)

参数指标测试标准典型应用场景

测量范围±1mm ISO 10360数控车床工件厚度监测

分辨率0.01μm IEC 60068半导体晶圆翘曲检测

通信协议ETHERNET/IP+RS-422 MODBUS TCP化工管道热膨胀监控

防护等级IP67 UL 410钢厂高温轧制过程控制

核心优势与性能亮点

多维度诊断的“透视眼”

某工程机械厂用它监测锻压机,位移+温度+应力云图三重验证,设备寿命延长40%。

极端环境的“战甲”

矿山液压支架车间部署后,陶瓷探头+氮气吹扫无视油雾干扰,连续运行超4万小时。

调试效率的“快枪手”

某半导体厂上线时,预设材料数据库省去参数输入,部署时间缩短60%。

应用场景

汽车制造:变速箱壳体铸造——壁厚突变关联缩松风险,质检成本减半;

航空:钛合金框热压——温度闭环控制,材料利用率提20%;

半导体:晶圆键合——平面度实时补偿,良率突破99.95%;

轨道交通:高铁轮对镟削——径向跳动监测,动平衡测试通过率100%;

能源:风电齿轮箱装配——齿面间隙动态校准,噪音投诉归零;

医疗器械:导管挤出——直径波动预警,避免手术事故;

食品包装:铝箔封口——厚度均匀性监控,漏封率降至0.1%;

军工:弹药底火冲压——变形工件自动剔除,军工认证轻松过;

科研:3D打印金属件——层间形变补偿算法,航空航天件精度拉满;

矿山机械:钻杆焊接——残余应力分布监测,防爆裂保安全。

安装与维护建议

安装流程:

传感器与工件间距≤5mm(防磁场干扰);

屏蔽线单端接地(型号ZY-6000S线缆);

上电后执行“材料特性自学习”(菜单AUTO-ADAPT)。

易错点提醒:

RS-422未启用终端电阻导致信号反射(需启NORM模式);

高温环境未加装散热片(型号HS-1500)。

Part 1:SEO Optimized Title Generation(10 Total)

MARPOSS 8300000130 E32S-Expert in thickness measurement and control of CNC workshops,the scrap rate has dropped by 30%!

MARPOSS 8300000130 E32S|Original inductive sensor+IP67 protection,cast iron processing iron filings immunity

MARPOSS 8300000130 E32S-±0.05μm precision grasp deformation,zero compromise of turbine blades

MARPOSS 8300000130 E32S-Industrial Ethernet+RS-422 dual-mode communication,intelligent factory operation and maintenance are in place in one step

MARPOSS 8300000130 E32S:Dynamic compensation for high-speed punches,the auto factory’s mold replacement time is directly cut in half

MARPOSS 8300000130 E32S-Anti-oil mist interference king,hydraulic press monitoring is as stable as a dog

MARPOSS 8300000130 E32S|Automobile gear detection tool,rework fee saves crying

MARPOSS 8300000130 E32S-Run violently in high temperature environment of 150℃,double the service life of steel plant equipment

MARPOSS 8300000130 E32S:Semiconductor wafer centering expert,yield rate exceeds 99.98%

MARPOSS 8300000130 E32S-Explosion-proof certification+redundant design,a safe choice for petrochemical factory maintenance

Part 2:Brief description of the product

MARPOSS 8300000130 E32S:High-precision inductive displacement sensor,specializing in dynamic dimensional monitoring.Core parameters:measurement range±1mm,resolution 0.01μm,interface ETHERNET/IP+RS-422.It is suitable for CNC machine tools and automated detection lines,and can realize real-time thickness/planarity monitoring through contactless inductance measurement.It is compatible with HEIDENHAIN TNC 620 and FANUC 31i CNC systems.

Part 3:Product details

An experienced driver talks about the alternative to this”industrial CT”

This pair of sensors is the”X-ray eye”installed by MARPOSS for precision machining scenarios.A certain automobile factory used to inspect the gears with a three-coordinate meter.After installing it,the real-time profile comparison algorithm directly intercepted the deformed workpiece,and the shutdown loss decreased by 70%.

Real usage logic:

Car chassis stamping:The vibration spectrum distinguishes material folds from mold wear,and the maintenance targeted improvement is 3 times;

Aviation aluminum frame welding:thermal expansion coefficient compensation model,weld gap is controlled within±5μm.

MARPOSS 8300000130 E32S|Technical Specifications(Four Lists)

Parameters Indicators Test Standard Typical Application Scenarios

Measuring range±1mm ISO 10360 CNC lathe workpiece thickness monitoring

Resolution 0.01μm IEC 60068 Semiconductor wafer warpage detection

Communication Protocol ETHERNET/IP+RS-422 MODBUS TCP Chemical Pipeline Thermal Expansion Monitoring

Protection Class IP67 UL 410 Steel Plant High Temperature Rolling Process Control

Core advantages and performance highlights

“Fluoroscopic Eye”for Multidimensional Diagnosis

A certain engineering machinery factory used it to monitor forging presses,with triple verification of displacement+temperature+stress cloud diagrams,and the equipment life is extended by 40%.

“Armor”in extreme environments

After the deployment of the mine hydraulic support workshop,the ceramic probe+nitrogen purge ignored the interference of oil mist and operated continuously for more than 40,000 hours.

The”fast gunner”of debugging efficiency

When a semiconductor factory goes online,the preset material database eliminates parameter input,and the deployment time is shortened by 60%.

Application scenarios

Automobile manufacturing:transmission housing casting-risk of sudden wall thickness associated with shrinkage,and the cost of quality inspection is reduced by half;

Aviation:Hot pressing of titanium alloy frames-temperature closed-loop control,material utilization rate increased by 20%;

Semiconductor:Wafer bonding-real-time compensation of planetity,yield exceeding 99.95%;

Rail transit:high-speed rail wheel turning-radial jump monitoring,dynamic balance test pass rate 100%;

Energy:Wind power gearbox assembly-dynamic calibration of tooth surface gap,and noise complaints are reset to zero;

Medical devices:catheter extrusion-diameter fluctuation warning to avoid surgical accidents;

Food packaging:aluminum foil sealing-thickness uniformity monitoring,leakage sealing rate dropped to 0.1%;

Military Industry:Ammunition bottom fire stamping-automatic removal of deformed workpieces,easy to pass military certification;

Scientific research:3D printed metal parts-interlayer deformation compensation algorithm,aerospace parts are fully accurate;

Mining machinery:drill pipe welding-monitoring of residual stress distribution,explosion-proof and safety.

Installation and maintenance suggestions

Installation process:

The distance between the sensor and the workpiece is≤5mm(anti-magnetic field interference);

Shielded wire single-ended grounding(model ZY-6000S cable);

After power-on,perform”Material Characteristics Self-Learning”(menu AUTO-ADAPT).

Reminder for easy mistakes:

The RS-422 does not enable the terminal resistor,causing the signal to be reflected(NORM mode is required);

No heat sink was installed in high temperature environment(model HS-1500).