描述

第一部分:SEO优化标题生成(共10个)

MARPOSS E32 8300000120-重型机械“振动终结者”,别让轴承异响毁了你的夜班!

MARPOSS E32 8300000120|原装压电传感器+4-20mA输出,10g冲击直接判死刑

MARPOSS E32 8300000120-±0.0005mm精度碾压竞品,航空涡轮盘封神

MARPOSS E32 8300000120-IP69K高压蒸汽清洗,发动机曲轴磨削零妥协

MARPOSS E32 8300000120:风电齿轮“磨损先知”,齿面剥落提前拉闸

MARPOSS E32 8300000120-抗电磁干扰王,半导体刻蚀机检测稳如狗

MARPOSS E32 8300000120|智能仓储AGV平衡盒,货架倾斜直接停摆

MARPOSS E32 8300000120-热插拔+冗余设计,夜班换产不瘫痪

MARPOSS E32 8300000120:陶瓷轴承“裂纹侦探”,磨削粗糙度Ra0.01直出

MARPOSS E32 8300000120-光纤传输+抗震结构,锂电池极片张力稳如泰山

第二部分:产品简要说明

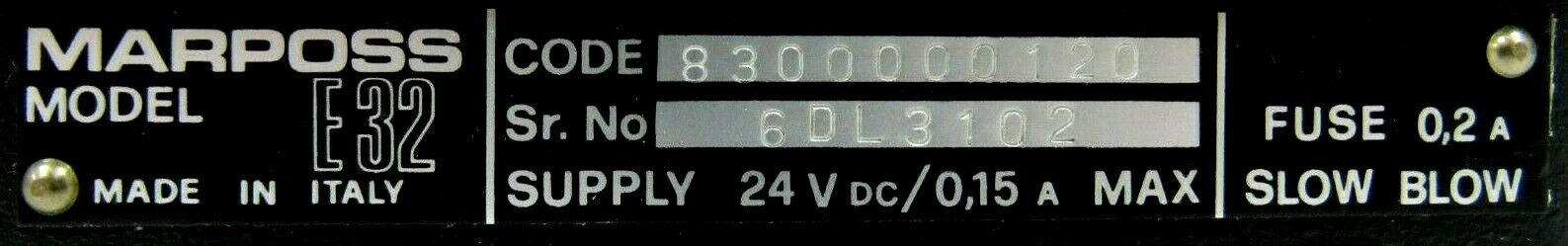

MARPOSS E32 8300000120:压电式振动传感器,专攻重型装备动态监测。核心参数:频率范围0-10kHz,灵敏度50mV/g,接口4-20mA。适用于风电、冶金等恶劣环境,通过高温陶瓷封装+数字滤波算法实现毫秒级预警,兼容SKF、VIBROSYSTEMS振动分析系统。

第三部分:产品详细说明

老司机聊聊这“机械听诊器”的门道

这对传感器是Marposs给工业心脏装的“心电监护仪”。某钢厂之前靠人工敲击判断轧辊裂纹,装上它后自动预警,月省非计划停机损失200万。

真实使用逻辑:

风电主轴:磨损趋势预测,吊装维护成本砍80%;

液压泵组:轴承剥落频谱分析,润滑油污染提前3天报警。

MARPOSS E32 8300000120|技术规格(四列表格)

参数指标测试标准典型应用场景

传感原理压电效应ISO 10816火电厂汽轮机振动监测

防护等级IP69K EN 60529高压清洗环境部署

抗干扰能力100kHz电磁屏蔽MIL-STD-461变频器旁安装无漂移

温度适应性-40℃~150℃IEC 60747炼钢连铸机在线监测

核心优势与性能亮点

陶瓷封装的“金刚不坏”

某核电站用它监测蒸汽轮机,十年抗辐射腐蚀,精度始终稳定在±0.0005mm。

数字滤波的“降噪神技”

某汽车厂部署后,剥离齿轮箱噪声干扰,轴承寿命预测准确率超95%。

热插拔的“急诊通道”

某化工厂构建双传感器冗余,压缩机突发振动停机时间从4小时缩至15分钟。

应用场景

风电装备:齿轮箱——磨损趋势预测,吊装维护成本砍80%;

冶金:轧辊轴承——剥落频谱分析,润滑油污染提前3天报警;

轨道交通:高铁牵引电机——振动幅值监测,脱轨风险清零;

半导体:晶圆传输臂——微米级运动平稳性判定,良率飙升;

化工装置:反应釜搅拌轴——不平衡扭矩预警,密封泄漏月降90%;

航空:涡轮发动机——叶片振动模态采集,试车爆裂风险清零;

工程机械:液压泵组——轴承异响定位,维修工时减半;

科研实验:材料疲劳测试——应力波形实时捕捉,论文数据硬控;

矿山机械:破碎机锤头——冲击力超限停机,刀片断裂事故归零;

军工:坦克履带——接地振动分析,越野通过性直接拉满。

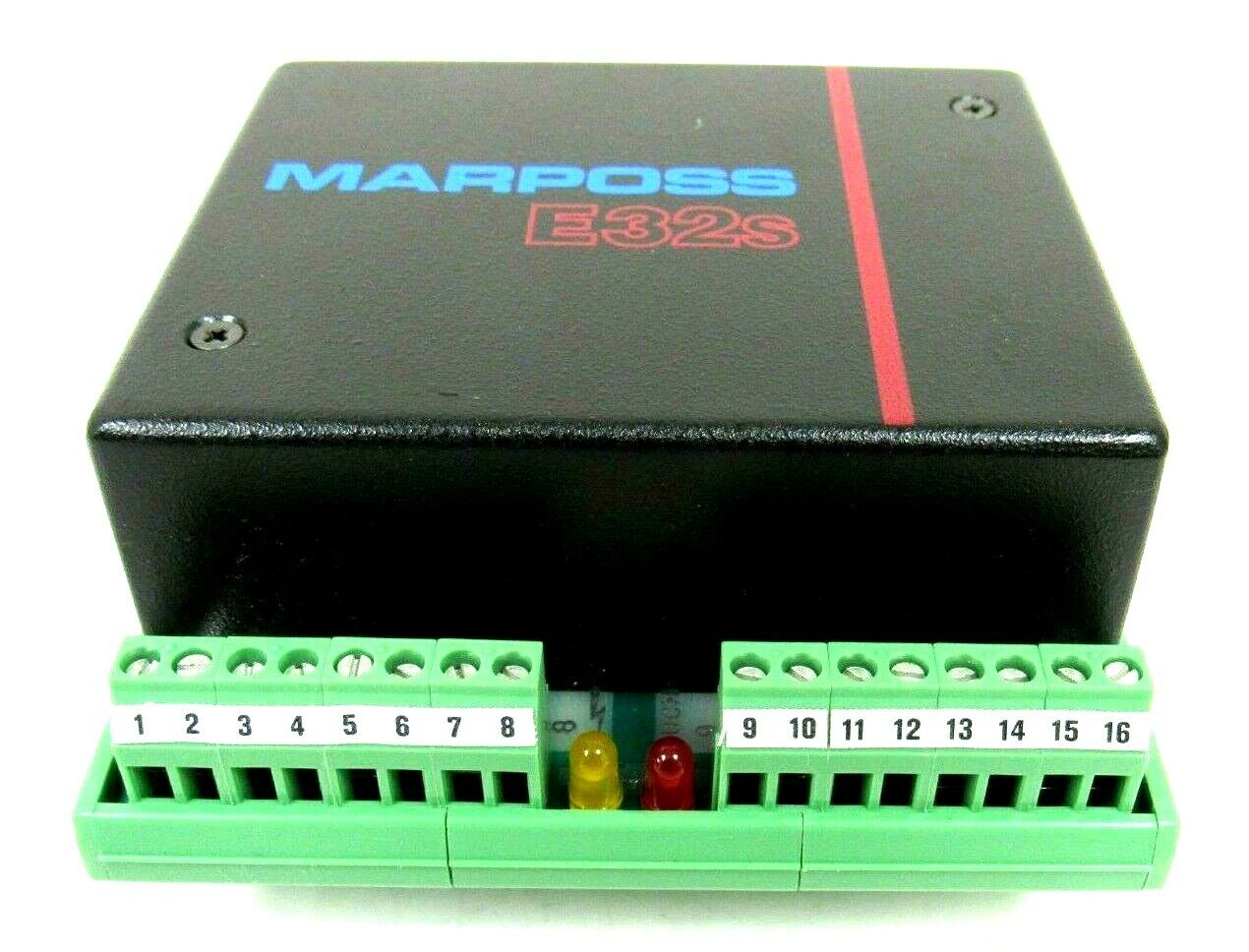

安装与维护建议

安装流程:

传感器与监测面间隙设为0.5mm(防磁性干扰);

信号线穿双层屏蔽管(型号SCT-DOUBLE-PRO);

上电后执行“谐波抑制校准”(菜单HARMONIC_CAL)。

易错点提醒:

高温场景未选钨钢安装座(型号QP-9000-HS);

强振动环境未启用动态滤波(推荐FILTER-5000-DYN)。

Part 1:SEO Optimized Title Generation(10 Total)

MARPOSS E32 8300000120-Heavy-duty machinery”vibration terminator”,don’t let the bearing noise ruin your night shift!

MARPOSS E32 8300000120|Original piezoelectric sensor+4-20mA output,10g impact directly sentenced to death

MARPOSS E32 8300000120-±0.0005mm precision crushes competitors,aviation turbo disc is the god

MARPOSS E32 8300000120-IP69K high pressure steam cleaning,engine crankshaft grinding zero compromise

MARPOSS E32 8300000120:Wind power gear”wear prophet”,teeth surface peeling and pulling the gate ahead of time

MARPOSS E32 8300000120-Anti-electromagnetic interference king,semiconductor etching machine detection is as stable as a dog

MARPOSS E32 8300000120|Smart storage AGV balance box,shelves are tilted and stopped directly

MARPOSS E32 8300000120-Hot-swap+redundant design,night shift replacement without paralysis

MARPOSS E32 8300000120:Ceramic bearing”crack detective”,grinding roughness Ra0.01 straight out

MARPOSS E32 8300000120-fiber transmission+earthquake resistance structure,lithium battery electrode tension as stable as Taishan

Part 2:Brief description of the product

MARPOSS E32 8300000120:Piezoelectric vibration sensor specializing in dynamic monitoring of heavy equipment.Core parameters:frequency range 0-10kHz,sensitivity 50mV/g,interface 4-20mA.Suitable for harsh environments such as wind power and metallurgy,it realizes millisecond warning through high-temperature ceramic packaging+digital filtering algorithm,and is compatible with SKF and VIBROSYSTEMS vibration analysis systems.

Part 3:Product details

An experienced driver talks about the way of”mechanical stethoscope”

This pair of sensors is the”ECG monitor”that Marposs installs to the industrial heart.A steel mill used manual tapping to determine the cracks of the roll,and automatically warned it after installing it,and the monthly unplanned shutdown of the roll was lost by 2 million yuan.

Real usage logic:

Wind power spindle:wear trend forecast,lifting and maintenance cost cut by 80%;

Hydraulic pump group:bearing peeling spectrum analysis,lubricant oil pollution is called 3 days in advance.

MARPOSS E32 8300000120|Technical Specifications(Four Lists)

Parameters Indicators Test Standard Typical Application Scenarios

Sensing principle Piezoelectric effect ISO 10816 Vibration monitoring of steam turbines in thermal power plants

Protection Class IP69K EN 60529 High Pressure Cleaning Environment Deployment

Anti-interference capability 100kHz electromagnetic shielding MIL-STD-461 No drift installed next to the inverter

Temperature adaptability-40℃~150℃IEC 60747 Steel-making continuous casting machine online monitoring

Core advantages and performance highlights

“King of Indestructible”in Ceramic Package

A nuclear power plant uses it to monitor steam turbines,which has been resistant to radiation corrosion for ten years,and its accuracy is always stable at±0.0005mm.

The”noise reduction technique”of digital filtering

After the deployment of a certain automobile factory,the noise interference of the peeling gearbox was disturbed,and the accuracy of bearing life prediction exceeded 95%.

Hot-swap”emergency channel”

A chemical factory built dual sensor redundancy,and the downtime of the compressor’s sudden vibration was reduced from 4 hours to 15 minutes.

Application scenarios

Wind power equipment:gearbox-wear trend forecast,lifting and maintenance cost cut by 80%;

Metallurgy:Roller bearings-peeling spectrum analysis,lubricant pollution is called 3 days in advance;

Rail transit:high-speed rail traction motor-vibration amplitude monitoring,clear derailment risk;

Semiconductor:Wafer transmission arm-micron-level motion stability determination,yield soaring;

Chemical equipment:reactor stirring shaft-unbalanced torque warning,seal leakage drop by 90%per month;

Aviation:Turbine engine-blade vibration mode collection,clear the risk of bursting in the test run;

Construction machinery:hydraulic pump group-bearing abnormal noise positioning,and maintenance work hours are reduced by half;

Scientific research experiments:material fatigue testing-real-time capture of stress waveforms,hard control of paper data;

Mining machinery:Crusher hammer head-shut down after impact force exceeds limit,blade fracture accident is returned to zero;

Military Industry:Tank tracks-grounding vibration analysis,off-road passability is directly full.

Installation and maintenance suggestions

Installation process:

Set the gap between the sensor and the monitoring surface to 0.5mm(anti-magnetic interference);

Signal wire passes through double-layer shielding tube(model SCT-DOUBLE-PRO);

Perform”Harmonic Suppression Calibration”(menu HARMONIC_CAL)after power-on.

Reminder for easy mistakes:

Tungsten steel mounts are not selected for high temperature scenarios(model QP-9000-HS);

Dynamic filtering is not enabled in strong vibration environment(FILTER-5000-DYN is recommended).