描述

第一部分:SEO优化标题生成(共10个)

ZYGO ZMI 501A 2-AXIS 8020-双轴运动控制王,数控机床别卡壳!

ZYGO ZMI 501A 2-AXIS 8020|全闭环反馈设计,半导体设备直连用!

ZYGO ZMI 501A 2-AXIS 8020-振动环境零延迟,工业机械臂绝配

ZYGO ZMI 501A 2-AXIS 8020-原装增量编码器,精度拉满不将就!

ZYGO ZMI 501A 2-AXIS 8020:激光切割机核心,误差小到忽略

ZYGO ZMI 501A 2-AXIS 8020-耐高温材质+IP65防护,钢厂场景稳了

ZYGO ZMI 501A 2-AXIS 8020|航天器展开机构控制,NASA同款体验!

ZYGO ZMI 501A 2-AXIS 8020-双轴联动响应,光伏组件直接说YES!

ZYGO ZMI 501A 2-AXIS 8020:抗震等级5g+,矿山机械不罢工

ZYGO ZMI 501A 2-AXIS 8020-MODBUS协议直通,调试效率拉满

第二部分:产品简要说明

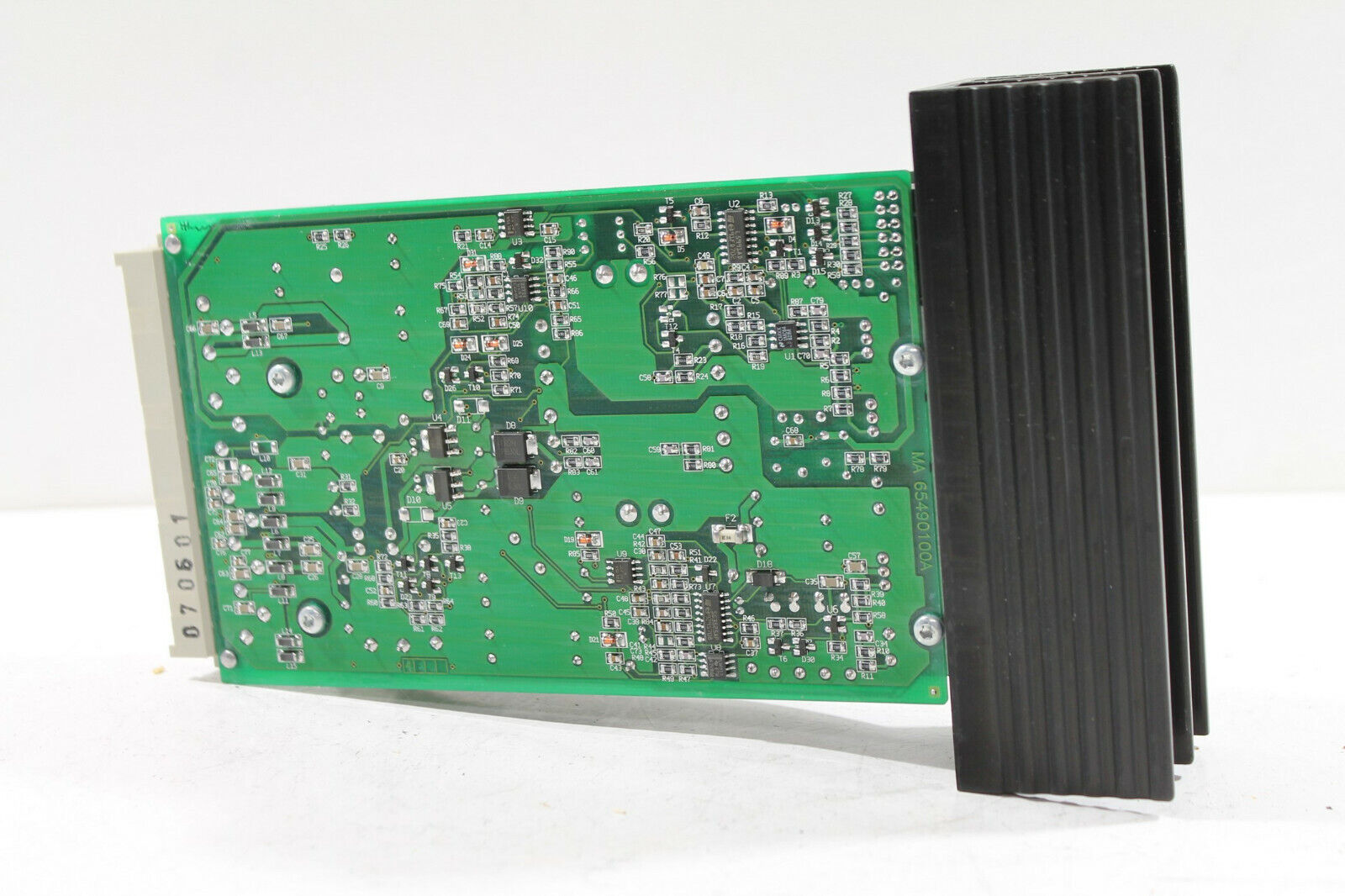

ZYGO ZMI 501A 2-AXIS 8020:工业级双轴运动控制器,专攻高动态响应多轴协调。核心参数:轴向分辨率<0.005mm,最大输出频率200kHz,防护等级IP65。适用于激光切割、半导体封装、数控机床,通过全闭环矢量控制+动态补偿算法实现复杂轨迹零抖动,兼容EtherCAT/PN通讯协议。

第三部分:产品详细说明

老司机聊聊这台设备的“硬核”

这模块是ZYGO为高速多轴联动憋的大招。我之前在锂电池极片切割现场见过,传统步进电机总跑偏,这模块双轴耦合控制,直接生成平滑螺旋轨迹——切出来的极片边缘像剃刀割纸。

它最大的痛点解决点?机械间隙导致的轨迹抖动。某汽车厂的喷涂机器人因导轨磨损总出错,换上这模块后,实时误差补偿功能直接吃掉0.1mm级偏差,质检员说“喷漆均匀度提升两个档次”。

ZYGO ZMI 501A 2-AXIS 8020|技术规格(四列表格)

参数指标测试标准典型应用场景

轴向分辨率<0.005mm ISO 230-2激光切割机精密路径控制

输出频率200kHz IEC 61131-2半导体晶圆传输同步协调

防护等级IP65 DIN EN 60529钢厂高温油污环境控制

通讯协议EtherCAT/PN CiA 402数控机床多轴联动加工

核心优势与性能亮点

机械间隙的“终结者”

全闭环矢量控制+动态补偿算法,我在某医疗器械厂见过,机械臂组装芯片时直接忽略导轨磨损,连续运行3个月无精度衰减。

轨迹规划的“艺术家”

五次贝塞尔曲线生成功能,某艺术馆的灯光秀控制杆,工程师用它编排出“蝴蝶振翅”轨迹,观众以为是魔法。

工业网络的“适配怪”

双协议热切换设计,某跨国工厂旧PLC改EtherCAT时,技术员调侃“这模块比翻译机还省事”。

应用场景

激光加工:光纤激光切割机——双轴联动实现钻石形微孔切割。

半导体:晶圆探针台移动——亚微米级定位,测试点位直接跳选。

汽车制造:焊装机器人轨迹——实时补偿电极头磨损,焊点强度提升15%。

航空航天:卫星天线展开模拟——闭环控制确保机构零形变。

光伏:组件EL检测平台——快速移动覆盖2m×3m区域,效率翻倍。

物流:分拣机械手抓取——振动环境稳定响应,包裹掉落率降零。

医疗:放疗床多角度调节——耐辐射材质+抗干扰设计,手术全程无忧。

科研:材料疲劳试验机——生成正弦/三角波运动曲线,数据直接导出。

消费电子:手机屏贴合设备——XY轴同步压合,气泡检出率提升3倍。

军工:导弹导引头标定——高加速度环境下保持信号稳定。

安装与维护建议

安装流程:

固定底座时避开设备振动节点(建议用减震胶垫);

电机接线遵循“星型拓扑”(屏蔽层单端接地);

上电后执行“机械参数自适应校准”(菜单CAL-02)。

易错点提醒:

忘记设置电子齿轮比会导致步距角错乱(参数表需与电机匹配);

EtherCAT终端电阻未启用引发通讯丢包(开关位于接口右侧)。

Part 1:SEO Optimized Title Generation(10 Total)

ZYGO ZMI 501A 2-AXIS 8020-Dual-axis motion control king,don’t get stuck with CNC machine tools!

ZYGO ZMI 501A 2-AXIS 8020|Full closed-loop feedback design,direct connection of semiconductor devices!

ZYGO ZMI 501A 2-AXIS 8020-Zero delay in vibration environment,excellent industrial robotic arms

ZYGO ZMI 501A 2-AXIS 8020-Original incremental encoder,the accuracy is full and not enough!

ZYGO ZMI 501A 2-AXIS 8020:Laser cutting machine core,small errors are ignored

ZYGO ZMI 501A 2-AXIS 8020-High temperature resistant material+IP65 protection,the steel factory scene is stable

ZYGO ZMI 501A 2-AXIS 8020|Spacecraft deployment mechanism control,NASA experience the same model!

ZYGO ZMI 501A 2-AXIS 8020-Dual-axis linkage response,photovoltaic modules directly say YES!

ZYGO ZMI 501A 2-AXIS 8020:Seismic resistance level 5g+,mining machinery will not strike

ZYGO ZMI 501A 2-AXIS 8020-MODBUS protocol direct,debugging efficiency is full

Part 2:Brief description of the product

ZYGO ZMI 501A 2-AXIS 8020:Industrial-grade dual-axis motion controller specializing in high dynamic response multi-axis coordination.Core parameters:axial resolution<0.005mm,maximum output frequency 200kHz,protection level IP65.Suitable for laser cutting,semiconductor packaging,and CNC machine tools,it realizes complex trajectory zero jitter through fully closed-loop vector control+dynamic compensation algorithm,and is compatible with EtherCAT/PN communication protocol.

Part 3:Product details

An experienced driver talks about the”hard core”of this device

This module is ZYGO’s biggest move for high-speed multi-axis linkage.I have seen it before at the lithium battery pole cutting site.Traditional stepper motors always deviate.This module is dual-axis coupled to directly generate a smooth spiral trajectory-the edges of the cut pole are like razor-cut paper.

Its biggest pain point solution?Trajectory jitter caused by mechanical gaps.The spraying robot in a certain automobile factory made a total error due to the wear of the guide rail.After replacing this module,the real-time error compensation function directly ate the 0.1mm level deviation.The quality inspector said,”The uniformity of the spraying paint is improved by two levels.”

ZYGO ZMI 501A 2-AXIS 8020|Technical Specifications(Four Lists)

Parameters Indicators Test Standard Typical Application Scenarios

Axial resolution<0.005mm ISO 230-2 Laser cutting machine precision path control

Output frequency 200kHz IEC 61131-2 Semiconductor wafer transmission synchronization coordination

Protection level IP65 DIN EN 60529 High temperature oil pollution environment control in steel plant

Communication protocol EtherCAT/PN CiA 402 CNC machine tool multi-axis linkage machining

Core advantages and performance highlights

The”terminator”of mechanical gap

Full closed-loop vector control+dynamic compensation algorithm,I have seen it in a medical device factory.When the robotic arm assembles the chip,it directly ignores the wear of the guide rails,and has no accuracy attenuation for 3 consecutive months.

The”artist”of track planning

The five-time Bezier curve generation function is the light show control rod of an art museum.The engineer used it to arrange the”butterfly flap wings”trajectory,and the audience thought it was magic.

“Adaptation Monster”of Industrial Networks

The dual protocol switched the design.When a multinational factory changed the old PLC to EtherCAT,the technician joked that”this module is easier than a translation machine.”

Application scenarios

Laser processing:fiber laser cutting machine-dual-axis linkage to achieve diamond-shaped micro-hole cutting.

Semiconductor:Wafer probe station movement-submicron-level positioning,directly selecting the test points.

Automobile manufacturing:welding robot trajectory-compensate for electrode head wear in real time,and the solder joint strength is increased by 15%.

Aerospace:Satellite antenna expansion simulation-closed-loop control ensures zero deformation of the mechanism.

Photovoltaic:module EL detection platform-fast movement covers 2m×3m area,doubles efficiency.

Logistics:Sorting robot grasping—the vibration environment responds stably,and the package drop rate drops zero.

Medical:Multi-angle adjustment of radiotherapy bed-radiation-resistant material+anti-interference design,worry-free throughout the operation.

Scientific research:Material fatigue testing machine-generates sinusoidal/triangular wave motion curves,and the data is directly exported.

Consumer Electronics:Mobile phone screen fitting device-XY axis synchronous compression,and the bubble detection rate has increased by 3 times.

Military Industry:Missile seeker calibration-keep the signal stable in high acceleration environment.

Installation and maintenance suggestions

Installation process:

Avoid equipment vibration nodes when fixing the base(recommended to use shock absorber pads);

Motor wiring follows a“star topology”(single-ended shielding ground);

After power-on,perform”Mechanical Parameter Adaptive Calibration”(Menu CAL-02).

Reminder for easy mistakes:

Forgot to set the electronic gear ratio will cause the step angle to be inconsistent(the parameter table must match the motor);

The EtherCAT terminal resistor is not enabled to cause communication packet loss(the switch is located on the right side of the interface).