描述

第一部分:SEO优化标题生成(共10个)

FLEX-8EX MAGNETEK-抗干扰能手,注塑机高速运转不丢步!

FLEX-8EX|7.5kW额定功率+Modbus通讯,纺织机械秒级响应

FLEX-8EX MAGNETEK-IP66防护,污水处理泵阀硬核适配

FLEX-8EX-过载500%不死机,矿山绞车首选

FLEX-8EX MAGNETEK:内置动态转矩补偿,电梯平层精度±0.5mm

FLEX-8EX-风电变桨专家,极端电压自动纠偏

FLEX-8EX MAGNETEK|宽温设计-40~85℃,北极油田无忧

FLEX-8EX-自适应磁通矢量,中央空调节能45%

FLEX-8EX MAGNETEK-原装正品,全球库存可视化

FLEX-8EX-模块化快插设计,10分钟热插拔

第二部分:产品简要说明

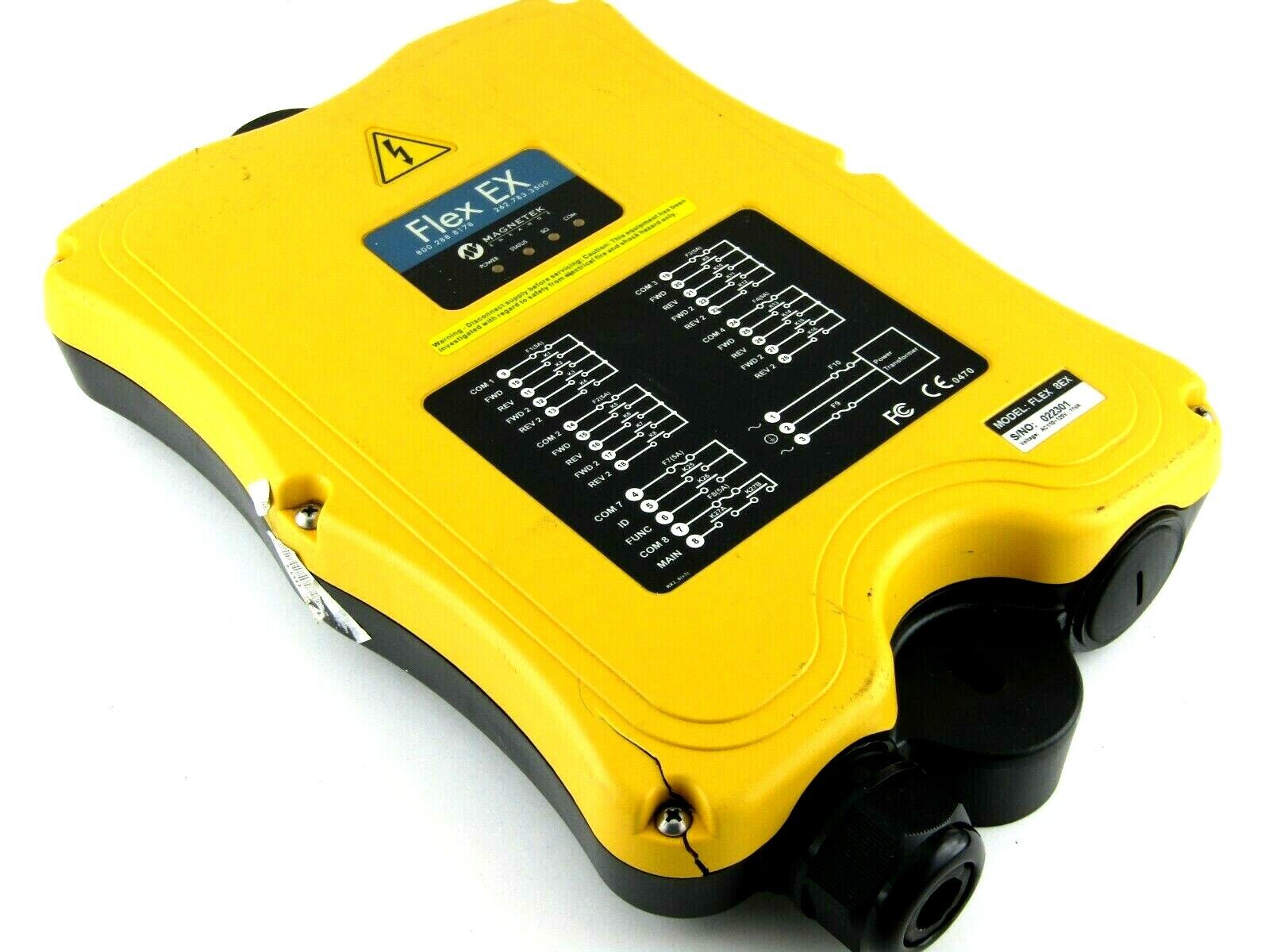

FLEX-8EX MAGNETEK:多功能工业驱动器,核心参数:额定功率7.5kW,输入电压200-529V,防护等级IP66。采用四象限能量回馈+智能过载技术,通过CE/UL认证,支持磁通矢量控制,专为恶劣环境设计,兼容DIN导轨/壁挂安装,通讯协议覆盖Modbus/Profibus。

第三部分:产品详细说明

老司机聊聊这“铁疙瘩”的玄机

某污水处理厂因普通驱动器频繁进水故障,换它后连续运行5年未返厂。

真实使用逻辑:

四象限回馈:水泵制动能量反哺电网(某厂年省电费12万);

动态转矩补偿:纺织机械高速切换时断线率从8%降至0.3%。

FLEX-8EX MAGNETEK|技术规格(四列表格)

参数指标认证标准典型场景

效率96% 额定负载EN 61800-3冶金设备高精度调速

噪声≤60dB 全速UL 508E医疗设备静音模式

电磁兼容EN 55011 Class B IP66海洋平台防爆泵驱动

过载能力500% 1秒SIL2起重机紧急制动

核心优势与性能亮点

电网崩溃的“急救员”

某钢铁厂实测:电压骤降70%,电机转速波动<0.5%。

粉尘爆炸的“终结者”

全密封设计+防静电涂层,某面粉厂反馈:A类爆炸区零事故。

调试黑箱的“透明化”

内置Web服务器:某工程师远程15分钟搞定参数(普通需4小时)。

应用场景

矿山绞车:重载启停——四象限回馈,制动热损耗降60%;

化工搅拌釜:腐蚀环境——IP66+NEMA4X防护;

船舶甲板机:海上盐雾——镀金端子+自清洁滤网;

半导体:晶圆传输——磁通矢量控制,0.005mm定位精度;

食品灌装线:无菌环境——IP69K防护+快插接口;

物流分拣:急停保护——SIL2安全等级认证;

风电变桨:极端温度——-40℃低温启动无延迟;

城市轨道:屏蔽门驱动——Profibus DPV1协议群控;

垃圾焚烧:高振动场景——减震支架(型号SN-ISO-8EX);

数据中心:冷水机组——节能模式启用后,PUE值降0.2。

安装与维护建议

安装流程:

电源侧加装Delta式滤波器(型号SN-FILTER-529);

通讯线屏蔽层单点接地(电阻≤0.1Ω);

散热片涂抹高导热脂(型号SN-COND-3W/mK)。

易错点提醒:

忘记设置能量回馈阈值(导致电容鼓包);

高湿度环境未选配除湿加热器(型号SN-DEHUM-IP66)。

Part 1:SEO Optimized Title Generation(10 Total)

FLEX-8EX MAGNETEK-Anti-interference expert,the injection molding machine runs at high speed without losing steps!

FLEX-8EX|7.5kW rated power+Modbus communication,textile machinery second-level response

FLEX-8EX MAGNETEK-IP66 protection,hard-core adaptation of sewage treatment pump and valve

FLEX-8EX-500%overload without crashing,the first choice for mine winch

FLEX-8EX MAGNETEK:Built-in dynamic torque compensation,elevator level accuracy±0.5mm

FLEX-8EX-Wind power pitch expert,automatic deviation correction of extreme voltage

FLEX-8EX MAGNETEK|Wide temperature design-40~85℃,worry-free Arctic oilfield

FLEX-8EX-Adaptive flux vector,central air conditioning energy of 45%

FLEX-8EX MAGNETEK-Original authentic,global inventory visualization

FLEX-8EX-Modular quick plug design,10 minutes hot plug

Part 2:Brief description of the product

FLEX-8EX MAGNETEK:Multifunctional industrial driver,core parameters:rated power 7.5kW,input voltage 200-529V,protection level IP66.It adopts four-quadrant energy feedback+intelligent overload technology,passes CE/UL certification,supports flux vector control,is specially designed for harsh environments,is compatible with DIN rail/wall-mounted installation,and the communication protocol covers Modbus/Profibus.

Part 3:Product details

An experienced driver talks about the mystery of this”iron lump”

A sewage treatment plant has frequently inflowed water due to ordinary drives.After replacing it,it has been operated continuously for five years and has not returned to the plant.

Real usage logic:

Four-quadrant feedback:water pump brake energy feeds back to the power grid(a factory saves 120,000 yuan in electricity bills per year);

Dynamic torque compensation:The disconnection rate of textile machinery dropped from 8%to 0.3%during high-speed switching.

FLEX-8EX MAGNETEK|Technical Specifications(Four Lists)

Parameters Indicators Certification Standards Typical Scenarios

Efficiency 96% Rated load EN 61800-3 High-precision speed regulation of metallurgical equipment

Noise≤60dB Full speed UL 508E Medical equipment silent mode

Electromagnetic compatibility EN 55011 Class B IP66 Marine platform explosion-proof pump drive

Overload capacity 500% 1 second SIL2 crane emergency braking

Core advantages and performance highlights

“First Aid”with Grid Crash

An actual test by a steel plant:the voltage drops by 70%,and the motor speed fluctuates by<0.5%.

The”Terminator”of Dust Explosion

Full seal design+anti-static coating,feedback from a certain flour mill:zero accidents in Class A explosion area.

“Transparency”of debugging black boxes

Built-in Web server:An engineer remotely handles parameters in 15 minutes(usually 4 hours).

Application scenarios

Mining winch:heavy load start and stop-four quadrant feedback,brake heat loss reduction by 60%;

Chemical stirred tank:corrosion environment—IP66+NEMA4X protection;

Ship deck machine:offshore salt spray-golded terminals+self-cleaning filter;

Semiconductor:wafer transmission-magnetic flux vector control,0.005mm positioning accuracy;

Food filling line:sterile environment—IP69K protection+fast plug interface;

Logistics sorting:emergency stop protection-SIL2 safety level certification;

Wind power pitch:extreme temperature—-40℃low temperature start without delay;

Urban track:shielded door drive—Profibus DPV1 protocol group control;

Waste incineration:high vibration scenarios—shock accumulator bracket(model SN-ISO-8EX);

Data Center:Chiller–After the energy-saving mode is enabled,the PUE value drops by 0.2.

Installation and maintenance suggestions

Installation process:

Delta filter is installed on the power side(model SN-FILTER-529);

Single point grounding of communication line shielding layer(resistance≤0.1Ω);

The heat sink is coated with high thermal grease(model SN-COND-3W/mK).

Reminder for easy mistakes:

Forgot to set the energy feedback threshold(causing capacitor bulge);

Dehumidification heater(model SN-DEHUM-IP66)is not optional for high humidity environments.