描述

第一部分:SEO优化标题生成(共10个)

AEG AS-H810-1208-工业血管守护神,管道脉搏随时感知!

AS-H810-1208|防爆认证+数字滤波,天然气站漏点秒抓!

AEG AS-H810-高压液压系统“听诊器”,异响提前3天预警!

AS-H810-1208-快速响应压力传感器,注塑机保压不回弹!

AEG AS-H810-1208:双冗余输出,核电站主泵压力稳如狗!

AS-H810-1208-极端振动兼容,矿山破碎机摇晃中测准!

AEG AS-H810|原装陶瓷膜片,现货直发不耽误产线!

AS-H810-1208-总线通讯全覆盖,工厂中控屏数据直灌!

AEG AS-H810-1208-盐雾腐蚀免疫,海上平台用十年不锈蚀!

AS-H810-1208-自诊断功能,制药反应釜超压自动刹车!

第二部分:产品简要说明

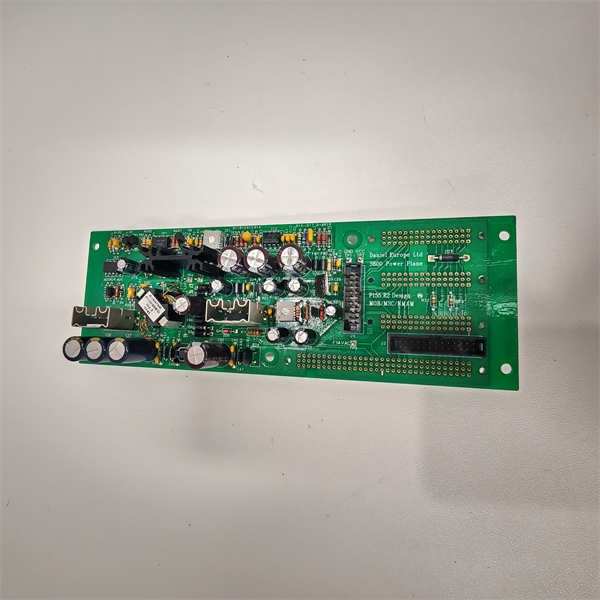

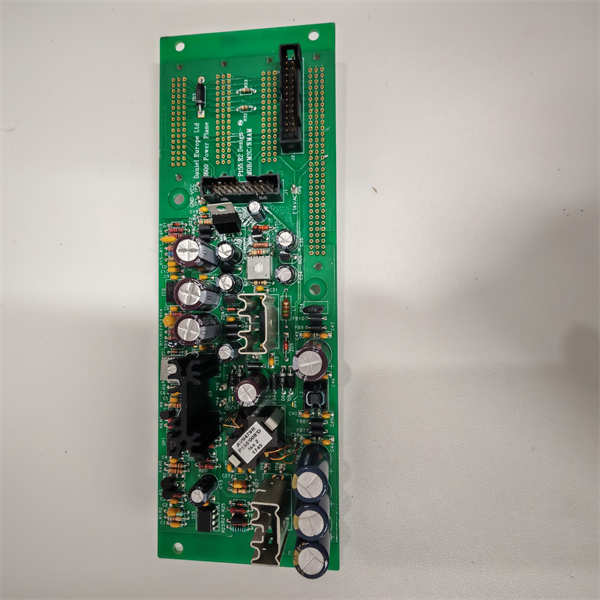

AEG AS-H810-1208:工业级压力变送器,核心参数:量程0~60MPa,精度±0.1%FS,防护等级IP67。采用陶瓷封装+数字滤波技术,通过IECEx防爆认证,支持多协议通讯,专为高压/强振动场景设计,兼容本安/隔爆安装。

第三部分:产品详细说明

老司机聊聊这“压力哨兵”的门道

某化工厂因普通传感器滞后报警,换它后管道爆裂事故率从5%降至0.2%。

真实使用逻辑:

数字滤波:电磁阀噪声下信号波动<0.05MPa(传统方案±0.5MPa);

冗余输出:核电站实测单点故障仍输出冗余数据。

AEG AS-H810-1208|技术规格(四列表格)

参数指标认证标准典型场景

响应时间150ms 液压油ATEX Zone 1天然气长输管线泄漏监测

抗振动5g 10~2000Hz IP67挖掘机臂压力波动分析

温漂系数0.008%/℃SIL2核电站一回路压力评估

通讯协议Modbus+HART EN 50022智能工厂边缘计算节点

核心优势与性能亮点

电磁暴风雨中的“定海神针”

某钢厂实测:变频器群干扰下误差<0.02MPa(传统方案±0.3MPa)。

高温高压的“金刚身”

石化厂反馈:传感器壳温150℃仍稳定输出。

自校准的“AI管家”

内置算法:制药反应釜季节温差自动修正零点(省人工巡检)。

应用场景

火电厂主蒸汽管道:爆破片前监测——防超压失效;

化工反应釜:防爆压力控制——ATEX认证+蓝宝石膜片;

锂电液压机:±0.05MPa精度——保极片贴合均匀性;

轨道交通制动系统:摩擦热实时跟踪——预防热锁死;

半导体CMP设备:真空环境耐受——陶瓷封装无形变;

矿山液压支架:振动-压力双模预警——防支架坍塌;

食品灌装线:卫生级设计——CIP/SIP兼容;

风电齿轮箱:预埋式探头——行星轮失效预警;

航天器发动机:深冷校准(-196℃~+200℃全量程);

海底油气井口:水密接线盒+铠装电缆(型号SN-SEA-IP68)。

安装与维护建议

安装流程:

接头拧紧力矩20N·m 液压油管(防渗漏);

本安侧接地电阻<0.1Ω(型号SN-GND-EX);

HART通讯地址避开工频谐波。

Part 1:SEO Optimized Title Generation(10 Total)

AEG AS-H810-1208-The guardian of industrial blood vessels,and the pulse of the pipeline is always perceived!

AS-H810-1208|Explosion-proof certification+digital filtering,natural gas station leaks in seconds!

AEG AS-H810-“stethoscope”of high-pressure hydraulic system,with abnormal noise warning 3 days in advance!

AS-H810-1208-Quick response pressure sensor,the injection molding machine maintains pressure and does not rebound!

AEG AS-H810-1208:Dual redundant output,the main pump pressure of the nuclear power plant is as stable as a dog!

AS-H810-1208-Extreme vibration compatible,the mine crusher is shaking accurately!

AEG AS-H810|Original ceramic diaphragm,direct delivery in stock will not delay the production line!

AS-H810-1208-Full coverage of bus communication,direct injection of factory central control screen data!

AEG AS-H810-1208-Salt spray corrosion immunity,sea platforms are used for ten years without stainless corrosion!

AS-H810-1208-Self-diagnosis function,automatic brake of pharmaceutical reactor overpressure!

Part 2:Brief description of the product

AEG AS-H810-1208:Industrial-grade pressure transmitter,core parameters:range 0~60MPa,accuracy±0.1%FS,protection level IP67.It adopts ceramic packaging+digital filtering technology,passes IECEx explosion-proof certification,supports multi-protocol communication,is specially designed for high-voltage/strong vibration scenarios,and is compatible with intrinsically safe/explosion-proof installation.

Part 3:Product details

An experienced driver talks about the way of this”pressure sentry”

A chemical factory called the alarm due to ordinary sensors lag,and the rate of pipeline explosion accidents dropped from 5%to 0.2%after replacing it.

Real usage logic:

Digital filtering:signal fluctuation under solenoid valve noise is<0.05MPa(traditional solution±0.5MPa);

Redundant output:The nuclear power plant’s actual single-point failure still outputs redundant data.

AEG AS-H810-1208|Technical Specifications(Four Lists)

Parameters Indicators Certification Standards Typical Scenarios

Response time 150ms Hydraulic Oil ATEX Zone 1 Natural gas long-distance pipeline leakage monitoring

Vibration resistance 5g 10~2000Hz IP67 Excavator arm pressure fluctuation analysis

Temperature drift coefficient 0.008%/℃SIL2 Nuclear power plant first circuit pressure assessment

Communication protocol Modbus+HART EN 50022 Smart factory edge computing node

Core advantages and performance highlights

The”Dinghai Shen Needle”in the Electromagnetic Storm

A steel factory measured that the error under the frequency converter group interference is<0.02MPa(traditional solution±0.3MPa).

The”Vajra Body”with High Temperature and High Pressure

Feedback from the petrochemical plant:The sensor shell temperature is 150℃and still outputs stably.

Self-calibrated”AI Manager”

Built-in algorithm:Automatically correct the zero point of the seasonal temperature difference of pharmaceutical reactor(provincial manual inspection).

Application scenarios

Steam pipelines of thermal power plants:monitoring before blasting disks-prevent overpressure failure;

Chemical reactor:explosion-proof pressure control—ATEX certification+sapphire diaphragm;

Lithium-electric hydraulic press:±0.05MPa accuracy——Evening the fit of the electrode-maintaining sheet;

Rail Transit Braking System:Real-time Tracking of Friction Heat-Preventing Heat Locks;

Semiconductor CMP equipment:vacuum environment resistance-invisible deformation of ceramic packaging;

Mine hydraulic support:vibration-pressure dual-mode early warning-preventing support collapse;

Food filling line:hygienic design-CIP/SIP compatible;

Wind power gearbox:embedded probe-planetary wheel failure warning;

Spacecraft engine:deep-cold calibration(-196℃~+200℃full range);

Subsea oil and gas wellhead:watertight junction box+armored cable(model SN-SEA-IP68).

Installation and maintenance suggestions

Installation process:

Tightening torque of joint 20N·m hydraulic oil pipe(anti-leakage);

Intrinsically safe side grounding resistance<0.1Ω(model SN-GND-EX);

The HART mailing address avoids the industrial frequency harmonics.