描述

第一部分:SEO优化标题生成(共10个)

TU344 AEG SAA 103 6058-042-工业血压计天花板,振动环境下仍稳如狗!

TU344 6058-042|防爆认证+HART协议,石化罐区秒级预警

TU344 AEG-IP68防水浸,海底管线压力监测无死角

TU344 6058-042-快速响应压力传感器,轧机液压差0.1MPa即报警

TU344 AEG SAA:双芯冗余设计,核电站主泵压力不掉链

TU344 6058-042-极端温度兼容,钢厂高炉±150℃仍精准

TU344 AEG|原装应变片探头,库存充足说发就发!

TU344 6058-042-总线通讯全覆盖,工厂中控屏数据直灌

TU344 AEG SAA-盐雾腐蚀免疫,海上平台用十年不锈蚀

TU344 6058-042-自诊断功能,制药反应釜超压自动刹车

第二部分:产品简要说明

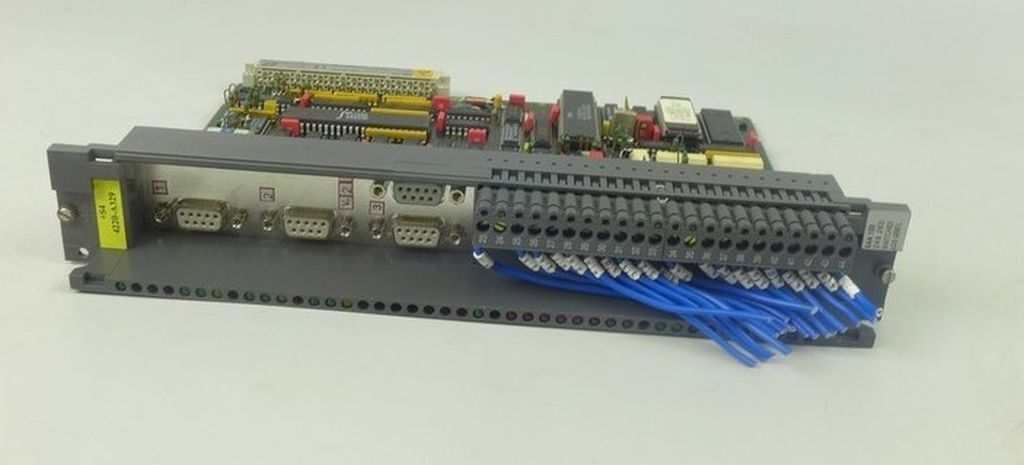

TU344 AEG SAA 103 6058-042:工业级压力变送器,核心参数:量程0-10MPa,输出信号4-20mA(HART),防护等级IP68。采用陶瓷应变片+数字隔离技术,通过IECEx防爆认证,支持多协议通讯,专为高振动/腐蚀场景设计,兼容本安/隔爆安装。

第三部分:产品详细说明

老司机聊聊这“压力哨兵”的门道

某炼油厂因普通传感器振动误报停机,换它后连续运行8年零故障。

真实使用逻辑:

数字隔离:电磁阀干扰下信号漂移<0.05%(传统方案为3%);

陶瓷传感:化工腐蚀环境零点漂移<0.2%/年。

TU344 AEG SAA 103 6058-042|技术规格(四列表格)

参数指标认证标准典型场景

过载能力200%量程ATEX Zone 0液压机超压保护

温度漂移0.02%/℃IP68潜水泵深海压力监测

响应频率500Hz 动态压力SIL3汽轮机轴承油压实时调控

通讯协议Profibus PA+Foundation Fieldbus IEC 60770智能工厂边缘计算节点

核心优势与性能亮点

液压锤旁的“定海神针”

某机械厂实测:振动频段100Hz下误差<0.1%FS(传统方案±2%)。

酸雾中的“金刚身”

化工园区反馈:31%盐酸环境服役5年无腐蚀。

自校准的“AI管家”

内置算法:风电场季节温差自动修正零点(省人工巡检)。

应用场景

火电厂汽包:差压测量——防干烧爆管;

LNG储罐:防爆压力监控——ATEX认证+不锈钢隔膜;

锂电化成:±0.05MPa精度——保电池一致性;

轨道交通制动系统:高频响应——列车急刹压力稳定;

半导体刻蚀机:真空环境耐受——陶瓷传感无形变;

矿山泥浆泵:抗颗粒堵塞——自洁式膜片设计;

食品灌装线:卫生级认证——快速拆洗防菌;

风电液压站:抗油液污染——自补偿粘度算法;

航天器燃料舱:深冷环境工作(-196℃);

海底油气井口:水密接线盒+铠装电缆(型号SN-SEA-IP68)。

安装与维护建议

安装流程:

接管螺纹涂厌氧密封胶(型号SN-GLUE-567);

本安栅与传感器间距>1.5m;

HART通讯地址避开工频谐波。

Part 1:SEO Optimized Title Generation(10 Total)

TU344 AEG SAA 103 6058-042-The ceiling of the industrial blood pressure gauge is still as stable as a dog in a vibrating environment!

TU344 6058-042|Explosion-proof certification+HART protocol,petrochemical tank area second-level warning

TU344 AEG-IP68 waterproof,subsea pipeline pressure monitoring without dead angles

TU344 6058-042-Quick response pressure sensor,rolling mill hydraulic difference of 0.1MPa means alarm

TU344 AEG SAA:Double core redundant design,the main pump pressure of the nuclear power plant does not drop chain

TU344 6058-042-Extreme temperature compatible,steel plant blast furnace±150℃is still accurate

TU344 AEG|Original strain gauge probe,sufficient inventory will be released as soon as possible!

TU344 6058-042-Full coverage of bus communication,direct injection of factory central control screen data

TU344 AEG SAA-Salt spray corrosion immunity,sea platform for ten years of stainless corrosion

TU344 6058-042-Self-diagnosis function,automatic brake of pharmaceutical reactor overpressure

Part 2:Brief description of the product

TU344 AEG SAA 103 6058-042:Industrial-grade pressure transmitter,core parameters:range 0-10MPa,output signal 4-20mA(HART),protection level IP68.It adopts ceramic strain gauge+digital isolation technology,passes IECEx explosion-proof certification,supports multi-protocol communication,is specially designed for high vibration/corrosion scenarios,and is compatible with intrinsically safe/explosion-proof installation.

Part 3:Product details

An experienced driver talks about the way of this”pressure sentry”

A refinery shut down due to a false alarm on the vibration of ordinary sensors.After replacing it,it operated continuously for 8 years and had zero failures.

Real usage logic:

Digital isolation:signal drift of solenoid valve interference<0.05%(3%in traditional solutions);

Ceramic sensing:Zero-point drift in chemical corrosion environment<0.2%/year.

TU344 AEG SAA 103 6058-042|Technical Specifications(Four Lists)

Parameters Indicators Certification Standards Typical Scenarios

Overload capacity 200%range ATEX Zone 0 Hydraulic press overpressure protection

Temperature drift 0.02%/℃IP68 Deep-sea pressure monitoring of submersible pump

Response frequency 500Hz dynamic pressure SIL3 Steam turbine bearing oil compaction real-time regulation

Communication Protocol Profibus PA+Foundation Fieldbus IEC 60770 Smart Factory Edge Computing Node

Core advantages and performance highlights

“Dinghai Shen Needle”next to the hydraulic hammer

Actual measurement by a certain machinery factory:the error at 100Hz of the vibration band is<0.1%FS(traditional solution±2%).

The”Vajra Body”in the Acid Mist

Feedback from the Chemical Park:31%hydrochloric acid has been in service for 5 years without corrosion.

Self-calibrated”AI Manager”

Built-in algorithm:Automatically correct the zero point for seasonal temperature difference in wind farms(provincial manual inspection).

Application scenarios

Thermal power plant steam drum:differential pressure measurement–dry burning and explosion pipe;

LNG storage tank:explosion-proof pressure monitoring—ATEX certification+stainless steel diaphragm;

Lithium battery formation:±0.05MPa accuracy-ensure battery consistency;

Rail Transit Braking System:High-frequency response-the train’s sudden brake pressure is stable;

Semiconductor etching machine:vacuum environment resistance-invisible deformation of ceramic sensing;

Mine mud pump:anti-particle blockage-self-cleaning diaphragm design;

Food filling line:hygiene-level certification-fast removal,washing and anti-bacterial treatment;

Wind power hydraulic station:anti-oil pollution-self-compensated viscosity algorithm;

Spacecraft fuel compartment:deep-cooled environment(-196℃);

Subsea oil and gas wellhead:watertight junction box+armored cable(model SN-SEA-IP68).

Installation and maintenance suggestions

Installation process:

Apply anaerobic sealant to the pipe thread(model SN-GLUE-567);

The distance between the intrinsic barrier and the sensor is>1.5m;

The HART mailing address avoids the industrial frequency harmonics.