描述

第一部分:SEO优化标题生成(共10个)

W854 AEG DEP 216 6728 042.244630-振动监测“透视眼”,轴承异响提前3天报警!

W854 042.244630|防爆认证+数字滤波,石化机组秒级预警

W854 AEG-IP67防水浸,污水处理泵站泥里泡着也精准

W854 6728-快速响应振动传感器,轧钢辊缝0.1μm变形即抓拍

W854 AEG DEP:双探头冗余设计,核电站汽轮机监测不掉链

W854 042.244630-极端振动兼容,矿山颚式破碎机摇晃中稳如泰山

W854 AEG|原装压电陶瓷探头,现货直发不等急!

W854 6728-总线通讯全覆盖,工厂中控屏数据直灌

W85˂AEG DEP-盐雾腐蚀免疫,海上风电平台用十年不锈蚀

W854 042.244630-自诊断功能,制药混合机超振自动停机

第二部分:产品简要说明

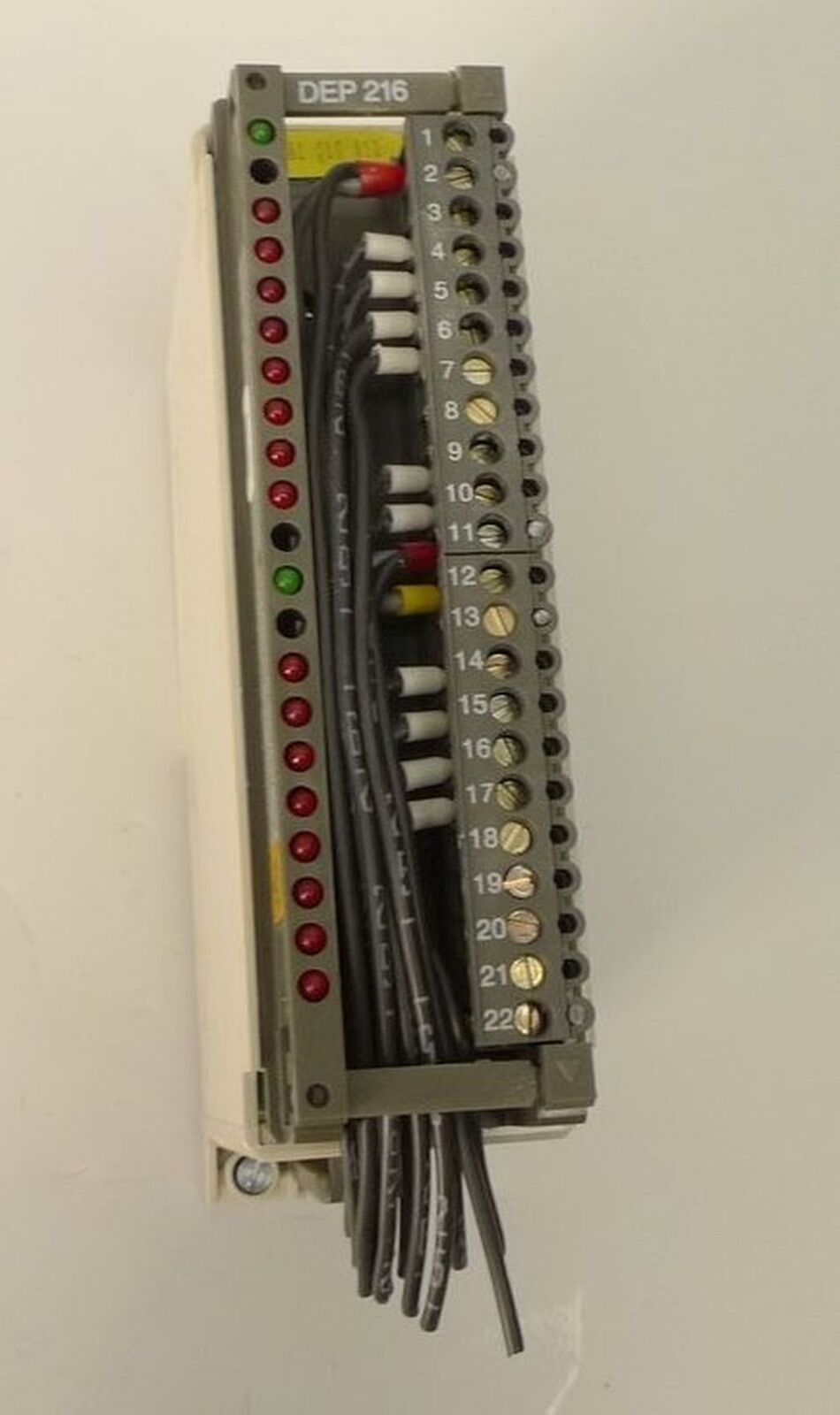

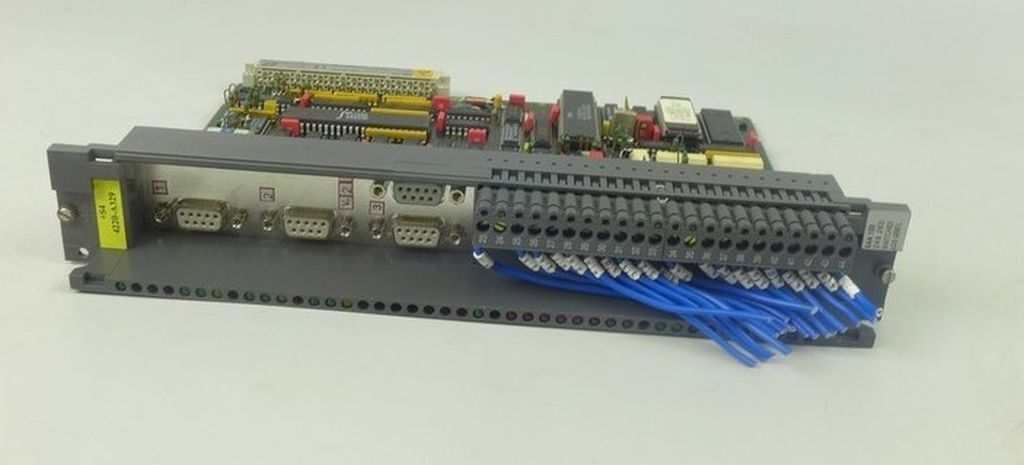

W854 AEG DEP 216 6728 042.244630:工业级振动变送器,核心参数:测量范围0.01~20mm/s,输出信号4-20mA+RS485,防护等级IP67。采用压电陶瓷+数字解调技术,通过IECEx防爆认证,支持多协议通讯,专为高振动/强电磁干扰场景设计,兼容本安/隔爆安装。

第三部分:产品详细说明

老司机聊聊这“振动雷达”的门道

某水泥厂因普通传感器漏检齿轮磨损,换它后提前72小时预警停机。

真实使用逻辑:

数字解调:变频器干扰下信噪比提升20dB(传统方案噪声淹没信号);

冗余探头:风电场实测单点失效仍输出原始波形。

W854 AEG DEP 216 6728 042.244630|技术规格(四列表格)

参数指标认证标准典型场景

频率响应1~10kHz 高通ATEX Zone 1汽轮机轴承磨损监测

抗冲击500g 半正弦IP67矿山液压锤振动分析

温漂系数0.03%/℃SIL2核电站主泵状态评估

通讯协议Modbus TCP+Profinet EN 50271智能工厂预测性维护

核心优势与性能亮点

电磁炉旁的“隔音房”

某电子厂实测:变频器噪声下信噪比>30:1(传统方案<2:1)。

高温暴晒的“耐力王”

沙漠光伏电站反馈:传感器壳温100℃仍稳定输出。

自诊断的“预判大师”

内置算法:化工泵组异常振动频谱自动拆解(省频谱仪成本)。

应用场景

火电厂汽轮机:轴承磨损监测——防飞车事故;

化工离心泵:防爆振动监控——ATEX认证+不锈钢探杆;

锂电卷绕机:±0.02mm/s精度——保极片对齐;

轨道交通转向架:高频冲击识别——轮轴裂纹预警;

半导体晶圆厂:洁净室无接触测量——蓝宝石探头;

垃圾焚烧炉:振动-温度双模监测——防锤头断裂;

食品灌装线:卫生级设计——蒸汽灭菌兼容;

风电齿轮箱:预埋式探头——预防行星轮失效;

航天器发射台:真空环境校准——零点漂移<0.01%/年;

海底油气压缩机:水密接线盒+铠装电缆(型号SN-SEA-IP68)。

安装与维护建议

安装流程:

探头间隙设定为0.8~1.2mm(避免摩擦);

本安侧接地电阻<0.1Ω(型号SN-GND-EX);

RS485总线终端电阻配120Ω匹配器。

易错点提醒:

忘记配置抗混叠滤波(导致高频信号失真);

高振动环境未选环氧灌封探头(型号W854-EP)。

Part 1:SEO Optimized Title Generation(10 Total)

W854 AEG DEP 216 6728 042.244630-Vibration monitoring”perspective eye”,bearing abnormal noise is called 3 days in advance!

W854 042.244630|Explosion-proof certification+digital filtering,petrochemical unit second-level warning

W854 AEG-IP67 waterproof soaking,sewage treatment pump station soaks accurately

W854 6728-Quick response vibration sensor,rolling roll joint 0.1μm is deformed and then capture it

W854 AEG DEP:Double probe redundant design,nuclear power plant steam turbine monitoring cannot be lost

W854 042.244630-Extreme vibration compatibility,the mine jaw crusher is as stable as Taishan

W854 AEG|Original piezoelectric ceramic probe,direct delivery in stock is not urgent!

W854 6728-Full coverage of bus communication,direct injection of factory central control screen data

W85˂AEG DEP-Salt spray corrosion immunity,offshore wind power platform for ten years without stainless

W854 042.244630-Self-diagnosis function,ultra-vibration and automatic shutdown of pharmaceutical mixer

Part 2:Brief description of the product

W854 AEG DEP 216 6728 042.244630:Industrial-grade vibration transmitter,core parameters:measurement range 0.01~20mm/s,output signal 4-20mA+RS485,protection level IP67.It adopts piezoelectric ceramic+digital demodulation technology,passes IECEx explosion-proof certification,supports multi-protocol communication,is specially designed for high vibration/strong electromagnetic interference scenarios,and is compatible with intrinsically safe/explosion-proof installation.

Part 3:Product details

An experienced driver talks about the way of”vibration radar”

A cement factory was injured in the wear of the gears due to ordinary sensors,and after replacing it,the machine was shut down 72 hours in advance.

Real usage logic:

Digital demodulation:The signal-to-noise ratio is increased by 20dB under the interference of the inverter(the signal of noise flooding in traditional solutions);

Redundant probe:The wind farm measured single point failure still outputs the original waveform.

W854 AEG DEP 216 6728 042.244630|Technical Specifications(Four Lists)

Parameters Indicators Certification Standards Typical Scenarios

Frequency response 1~10kHz Qualcomm ATEX Zone 1 Steam turbine bearing wear monitoring

Impact resistance 500g semisine IP67 Vibration analysis of hydraulic hammer in mine

Temperature drift coefficient 0.03%/℃SIL2 Nuclear power plant main pump status evaluation

Communication Protocol Modbus TCP+Profinet EN 50271 Smart Factory Predictive Maintenance

Core advantages and performance highlights

“Soundproof room”next to the induction cooker

An electronics factory measured that the signal-to-noise ratio under the frequency converter noise is>30:1(traditional solution<2:1).

The”Endability King”exposed to high temperatures

Feedback from desert photovoltaic power station:The sensor shell temperature is 100℃and still outputs stably.

Self-diagnosis”Predictor”

Built-in algorithm:Automatic disassembly of abnormal vibration spectrum of chemical pump set(save spectrum instrument cost).

Application scenarios

Thermal power plant steam turbine:bearing wear monitoring-preventing speed accidents;

Chemical centrifugal pump:explosion-proof vibration monitoring—ATEX certification+stainless steel probe rod;

Lithium battery winding machine:±0.02mm/s accuracy——alignment of the polar-retaining sheet;

Rail Transit Bogies:High-frequency impact recognition-wheel axle crack warning;

Semiconductor Fabs:Clean Room Contactless Measurement-Sapphire Probe;

Waste incinerator:vibration-temperature dual-mode monitoring-anti-hammer head breakage;

Food filling line:sanitary design-steam sterilization compatible;

Wind power gearbox:pre-embedded probe-prevent planetary wheel failure;

Spacecraft launch pad:vacuum environment calibration—zero point drift<0.01%/year;

Subsea oil and gas compressor:watertight junction box+armored cable(model SN-SEA-IP68).

Installation and maintenance suggestions

Installation process:

The probe gap is set to 0.8~1.2mm(avoid friction);

Intrinsically safe side grounding resistance<0.1Ω(model SN-GND-EX);

The RS485 bus termination resistor is equipped with a 120Ωmatcher.

Reminder for easy mistakes:

Forgot to configure anti-aliasing filtering(causing high-frequency signal distortion);

Epoxy potting probe(model W854-EP)is not selected for high vibration environment.