描述

EMERSON A6110产品详情

一、产品概述

EMERSON A6110是艾默生(Emerson Electric Co.)旗下Control Techniques(现属尼得科集团)品牌推出的一款高性能通用型变频器,专为工业自动化场景设计,适用于风机、泵、压缩机、传送带等设备的调速控制。该产品以高可靠性、灵活配置和节能优化为核心特点,支持开环矢量控制(V/F)和闭环矢量控制(SVC),可满足不同负载类型的驱动需求。

二、技术规格与核心功能

1.功率范围与适配电机

额定功率:

单相200-240V:0.4kW~2.2kW(0.5HP~3HP)。

三相380-480V:0.75kW~22kW(1HP~30HP)。

适配电机类型:

支持异步电机(感应电机)和永磁同步电机(PMSM)(需选配编码器)。

最大电机转速:3000rpm(可扩展至6000rpm通过参数设置)。

2.控制模式与性能

开环矢量控制(V/F):

适用于风机、泵类负载,提供平方转矩特性,节能效果显著。

速度控制精度:±0.5%(额定转速下)。

闭环矢量控制(SVC):

需搭配编码器(如增量式、绝对式),适用于高精度定位、张力控制等场景。

速度控制精度:±0.01%,转矩响应时间:<10ms。

动态响应:

加减速时间:0.1s~3600s可调。

过载能力:150%额定电流1分钟,200%额定电流3秒。

3.通信与接口

标准接口:

数字输入(DI):4路(可扩展至8路),支持24V DC信号,用于启动/停止、正反转、多段速控制。

数字输出(DO):2路(可扩展至4路),继电器触点输出(额定250V AC/30V DC,0.5A)。

模拟量输入(AI):2路(0-10V/4-20mA可选),用于速度给定或PID反馈。

模拟量输出(AO):1路(0-10V/4-20mA可选),用于监控电流、频率或转速。

通信协议:

RS-485:支持Modbus RTU协议,可与PLC、HMI或上位机通信。

可选扩展模块:

Profibus-DP:连接西门子等PLC系统。

DeviceNet:适配罗克韦尔自动化网络。

EtherCAT/PROFINET:高速实时通信(需A6110-ET型号)。

4.保护与诊断功能

过载保护:实时监测电流,触发过载时自动降频或停机。

过压/欠压保护:输入电压超出±15%额定值时报警或停机。

过热保护:内置温度传感器,散热器温度超过85℃时降额运行。

短路保护:快速切断输出,防止IGBT模块损坏。

故障记录:存储最近10次故障代码,便于快速排查问题。

EMERSON A6110 Product Details

I.Product Overview

EMERSON A6110 is a high-performance general-purpose inverter launched by Control Techniques(now part of Nidec Group)under Emerson Electric Co.It is designed for industrial automation scenarios and is suitable for speed control of equipment such as fans,pumps,compressors,and conveyors.The product features high reliability,flexible configuration,and energy-saving optimization.It supports open-loop vector control(V/F)and closed-loop vector control(SVC)to meet the driving requirements of different load types.

II.Technical Specifications and Core Functions

1.Power Range and Adaptive Motor

Rated Power:

Single-phase 200-240V:0.4kW~2.2kW(0.5HP~3HP).

Three-phase 380-480V:0.75kW~22kW(1HP~30HP).

Applicable motor type:

Supports asynchronous motor(induction motor)and permanent magnet synchronous motor(PMSM)(encoder required).

Maximum motor speed:3000rpm(expandable to 6000rpm through parameter setting).

2.Control mode and performance

Open-loop vector control(V/F):

Suitable for fan and pump loads,providing square torque characteristics,and significant energy saving effect.

Speed control accuracy:±0.5%(at rated speed).

Closed-loop vector control(SVC):

Requires encoder(such as incremental,absolute),suitable for high-precision positioning,tension control and other scenarios.

Speed control accuracy:±0.01%,torque response time:<10ms.

Dynamic response:

Acceleration and deceleration time:0.1s~3600s adjustable.

Overload capacity:150%rated current for 1 minute,200%rated current for 3 seconds.

3.Communication and interface

Standard interface:

Digital input(DI):4 channels(expandable to 8 channels),support 24V DC signal,used for start/stop,forward/reverse,and multi-speed control.

Digital output(DO):2 channels(expandable to 4 channels),relay contact output(rated 250V AC/30V DC,0.5A).

Analog input(AI):2 channels(0-10V/4-20mA optional),used for speed setting or PID feedback.

Analog output(AO):1 channel(0-10V/4-20mA optional),used to monitor current,frequency or speed.

Communication protocol:

RS-485:supports Modbus RTU protocol,can communicate with PLC,HMI or host computer.

Optional expansion module:

Profibus-DP:connect to PLC systems such as Siemens.

DeviceNet:adapt to Rockwell Automation network.

EtherCAT/PROFINET:High-speed real-time communication(A6110-ET model required).

4.Protection and diagnostic functions

Overload protection:Real-time current monitoring,automatic frequency reduction or shutdown when overload is triggered.

Overvoltage/undervoltage protection:Alarm or shutdown when input voltage exceeds±15%of rated value.

Overheat protection:Built-in temperature sensor,derating operation when heat sink temperature exceeds 85℃.

Short circuit protection:Quickly cut off output to prevent damage to IGBT module.

Fault record:Store the last 10 fault codes for quick troubleshooting.

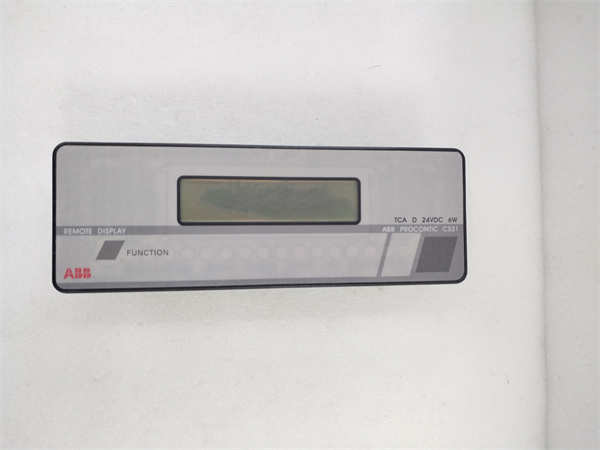

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101