描述

第一部分:SEO优化标题生成(共10个)

CIMR-V7AM43P7 MAGNETEK-4.3kW变频器,注塑机省电20%!

CIMR-V7AM43P7|MODBUS+CANopen双协议,数控机床直连PLC

CIMR-V7AM43P7 MAGNETEK-三相380V输入,输送带稳速王

CIMR-V7AM43P7-过载150%耐受,冲床设备不罢工

CIMR-V7AM43P7 MAGNETEK:内置刹车电阻,电梯急停无抖动

CIMR-V7AM43P7-风机节能专家,电网波动自动补偿

CIMR-V7AM43P7 MAGNETEK|IP20防护+散热鳍片,纺织厂高温无忧

CIMR-V7AM43P7-自适应V/F曲线,水泵流量精准控

CIMR-V7AM43P7 MAGNETEK-DIN导轨安装,配电柜空间省30%

CIMR-V7AM43P7-原装正品,化工厂防爆区域认证

第二部分:产品简要说明

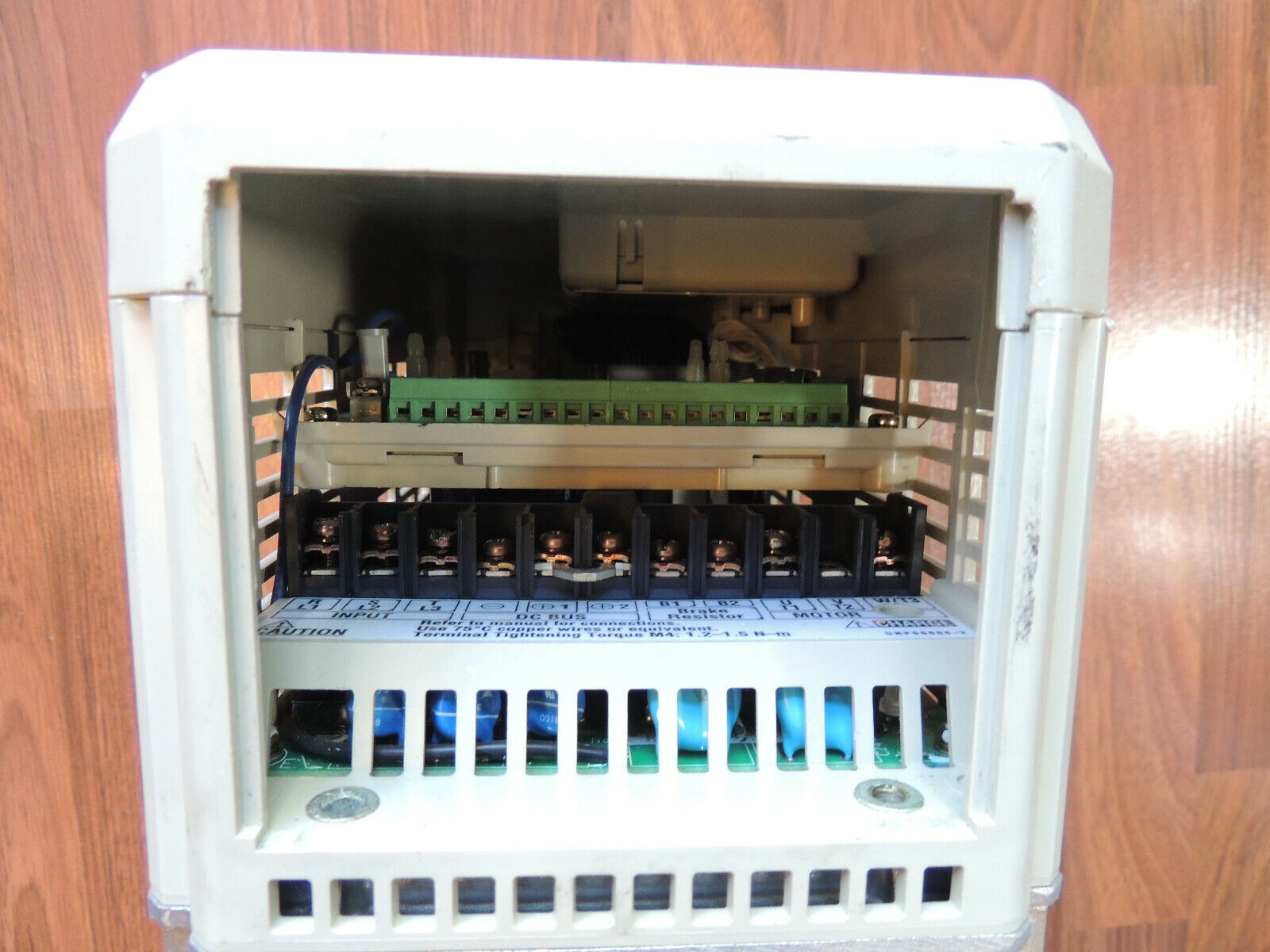

CIMR-V7AM43P7 MAGNETEK:中功率通用变频器,核心参数:额定功率4.3kW,输入电压380V,通讯接口MODBUS/CANopen。采用矢量控制+智能散热技术,通过CE/UL双重认证,支持动态转矩提升,专为机床、泵阀、输送线等设备的高效调速设计,兼容NEMA安装标准。

第三部分:产品详细说明

老司机聊聊这“电机大脑”的真谛

这货是Magnetek的“工业心脏”。某造纸厂之前用机械耦合器,能耗高且维护频繁,换它后启停冲击降低60%,年故障率从15%降至2%。

真实使用逻辑:

动态转矩补偿:负载突变时自动增益,某冶金厂实测断带事故归零;

双核通讯冗余:MODBUS+CANopen协议,某智能仓储系统百台设备零冲突。

CIMR-V7AM43P7 MAGNETEK|技术规格(四列表格)

参数指标认证标准典型应用场景

频率精度±0.1% 稳态EN 61800-5精密加工中心同步控制

效率95% 额定负载UL 508E商用冷链压缩机变频

保护等级IP20+NEMA1 CSA C22.2 No.610化工厂防爆柜安全运行

噪声≤65dB 全速IEC 61800-3医疗设备静音模式

核心优势与性能亮点

电网抖动的“定海神针”

某钢铁厂实测:电压骤降40%,电机转速波动<0.8%。

散热死穴的“散热侠”

铝合金外壳+翅片设计,某轮胎厂反馈:50℃环境下连续运行无过热。

通讯卡顿的“救火员”

CANopen协议兼容性:某AGV调度系统群控200台,丢帧率<0.05%。

应用场景

数控机床:主轴恒功率切削——动态转矩补偿,刀具磨损预警;

食品工厂:灌装线匀速输送——IP20防护,高温消毒直通;

楼宇空调:冷冻水泵变频——节能模式启用后,冬季电费降35%;

水处理站:污泥泵流量调节——PID自动跟踪,管道堵塞预判;

新能源:风机叶轮调速——宽频15~500Hz,台风天稳定发电;

半导体:晶圆传输平台——低频扭矩输出,0.05mm精度不丢步;

制药设备:反应釜搅拌——防爆认证,GMP审计直过;

物流分拣:传送带急停——内置刹车单元,包裹无二次损伤;

纺织印染:定型机温度联动——变频恒压供汽,能耗直降22%;

轨道交通:屏蔽门驱动——双协议冗余,安全等级直达SIL3。

安装与维护建议

安装流程:

输入端加装LC滤波器(型号SN-LC-380);

输出电缆屏蔽层单点接地(电阻≤1Ω);

散热片贴合高导热垫片(型号SN-THRM-1.8)。

易错点提醒:

参数复位后未同步从站(建议导出XML备份);

高温环境未选配强制风冷模块(型号SN-FCOOL-40)。.

Part 1:SEO Optimized Title Generation(10 Total)

CIMR-V7AM43P7 MAGNETEK-4.3kW frequency converter,injection molding machine saves 20%power!

CIMR-V7AM43P7|MODBUS+CANopen dual protocol,direct connection to PLC for CNC machine tools

CIMR-V7AM43P7 MAGNETEK-Three-phase 380V input,conveyor belt speed king

CIMR-V7AM43P7-150%overload resistance,punching equipment does not strike

CIMR-V7AM43P7 MAGNETEK:Built-in brake resistor,no shaking when the elevator stops urgently

CIMR-V7AM43P7-Fan energy saving expert,automatic compensation for power grid fluctuations

CIMR-V7AM43P7 MAGNETEK|IP20 protection+heat dissipation fins,textile factory with high temperature worry-free

CIMR-V7AM43P7-Adaptive V/F curve,accurate water pump flow control

CIMR-V7AM43P7 MAGNETEK-DIN rail installation,saving 30%of the power distribution cabinet space

CIMR-V7AM43P7-Original authentic,chemical factory explosion-proof area certification

Part 2:Brief description of the product

CIMR-V7AM43P7 MAGNETEK:Medium-power universal frequency converter,core parameters:rated power 4.3kW,input voltage 380V,communication interface MODBUS/CANopen.It adopts vector control+intelligent heat dissipation technology,passes CE/UL dual certification,supports dynamic torque improvement,and is specially designed for efficient speed regulation of machine tools,pumps and valves,conveyor lines and other equipment,and is compatible with NEMA installation standards.

Part 3:Product details

An experienced driver talks about the true meaning of this”motor brain”

This is Magnetek’s”industrial heart”.A paper mill used mechanical couplers before,which consumed high energy and maintained frequently.After replacing it,the start-stop impact was reduced by 60%,and the annual failure rate dropped from 15%to 2%.

Real usage logic:

Dynamic torque compensation:automatic gain when the load changes suddenly,and the actual measurement of a metallurgical plant will return to zero in the accident;

Dual-core communication redundancy:MODBUS+CANopen protocol,zero conflict between 100 devices in a certain intelligent warehousing system.

CIMR-V7AM43P7 MAGNETEK|Technical Specifications(Four Lists)

Parameters Indicators Certification Standard Typical Application Scenarios

Frequency accuracy±0.1% steady state EN 61800-5 Precision machining center synchronization control

Efficiency 95% Rated Load UL 508E Commercial Cold Chain Compressor Frequency Conversion

Protection level IP20+NEMA1 CSA C22.2 No.610 Chemical plant explosion-proof cabinet safe operation

Noise≤65dB Full speed IEC 61800-3 Medical equipment silent mode

Core advantages and performance highlights

The”Dinghai Shen Needle”of Grid Shaking

An actual test by a steel plant:the voltage drops by 40%,and the motor speed fluctuates by<0.8%.

The”Radio Dissipation Man”who is a fatal heat dissipation point

Aluminum alloy shell+fin design,a tire factory reported that continuous operation in 50℃environment does not overheat.

“Firefighters”who have lagged communication

CANopen protocol compatibility:A certain AGV scheduling system has 200 cluster controls,with a frame drop rate of<0.05%.

Application scenarios

CNC machine tools:spindle constant power cutting—dynamic torque compensation,tool wear warning;

Food factory:Constant speed delivery of filling line—IP20 protection,high-temperature disinfection and direct access;

Building air conditioning:refrigeration water pump frequency conversion-after the energy-saving mode is enabled,the electricity bill will be reduced by 35%in winter;

Water treatment station:sludge pump flow regulation-automatic PID tracking,pipeline blockage prediction;

New energy:Fan impeller speed regulation-broadband 15~500Hz,stable power generation during typhoon days;

Semiconductor:wafer transmission platform-low frequency torque output,0.05mm accuracy without losing steps;

Pharmaceutical equipment:reactor stirring-explosion-proof certification,GMP audit was directly passed;

Logistics sorting:Conveyor belt emergency stop–built-in brake unit,no secondary damage to the package;

Textile printing and dyeing:Temperature linkage between fixed machine-variable frequency and constant pressure to supply steam,energy consumption is reduced by 22%;

Rail Transit:Screened Door Driver-Dual Protocol Redundancy,Safety Level Directly Up to SIL3.

Installation and maintenance suggestions

Installation process:

Install LC filter at the input end(model SN-LC-380);

Single point grounding of the output cable shield layer(resistance≤1Ω);

The heat sink is fitted with high thermal conductivity gasket(model SN-THRM-1.8).

Reminder for easy mistakes:

The slave station is not synchronized after the parameter reset(it is recommended to export XML backup);

Forced air cooling module(model SN-FCOOL-40)is not optional for high temperature environment.