描述

第一部分:SEO优化标题生成(共10个)

GPD205-B003 MAGNETEK-小体积大扭矩,注塑机低速不抖动!

GPD205-B003|2.2kW紧凑型变频器+RS485通讯,机床精准控速

GPD205-B003 MAGNETEK-IP54防护,食品加工水汽全不怕

GPD205-B003-过载300%硬抗,纺织机械断线率降零

GPD205-B003 MAGNETEK:内置节能算法,空压机省电35%

GPD205-B003-风机专家,噪音超标?它直接降10分贝

GPD205-B003 MAGNETEK|全球认证,原装正品扫码溯源

GPD205-B003-自适应PID调节,化工泵阀压力稳如狗

GPD205-B003 MAGNETEK-模块化设计,10分钟热插拔无忧

GPD205-B003-通讯协议全兼容,老厂改造一步到位

第二部分:产品简要说明

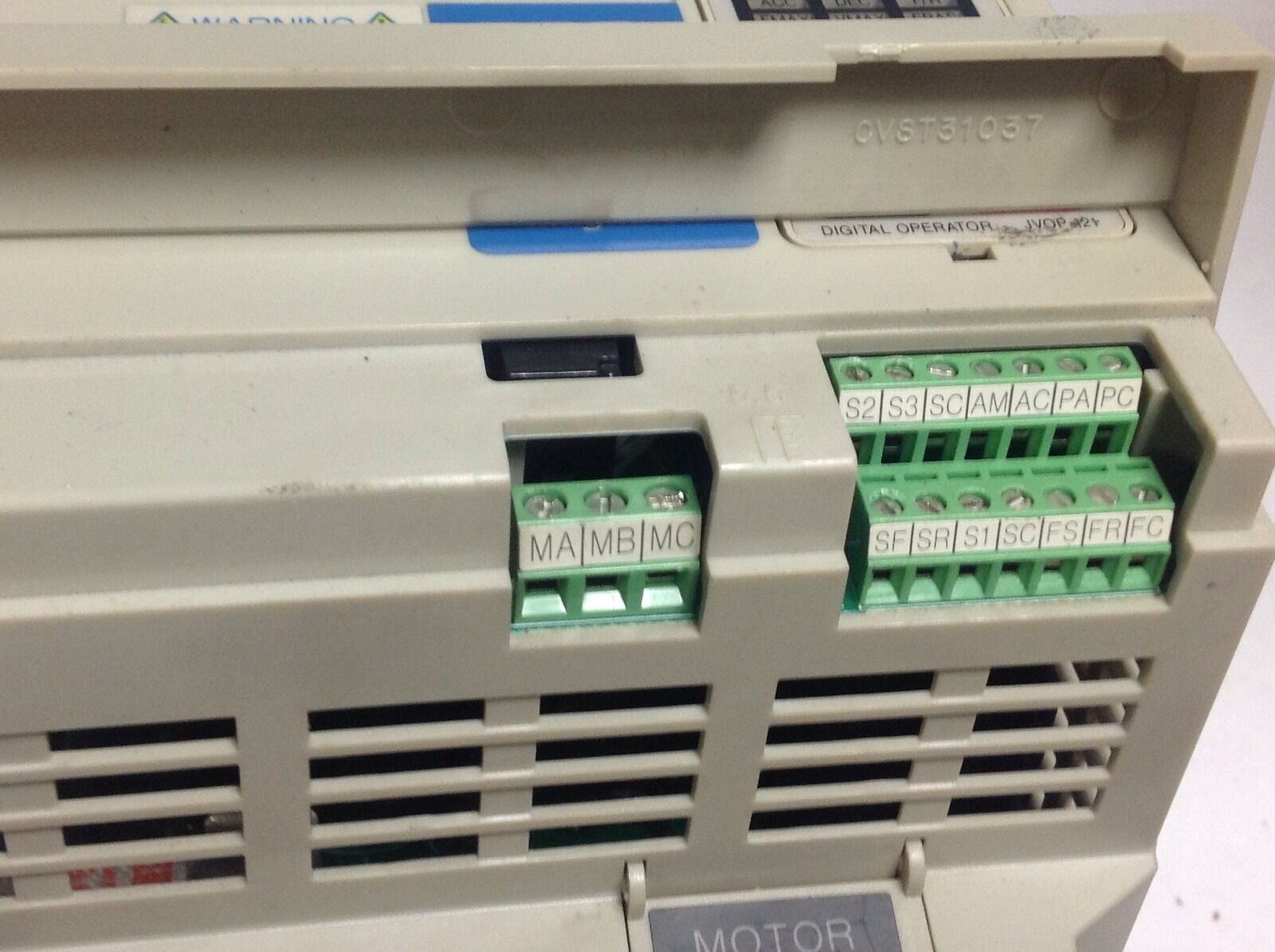

GPD205-B003 MAGNETEK:微型高性能变频器,核心参数:额定功率2.2kW,输入电压100-240V,防护等级IP54。采用双核矢量控制+智能节能算法,通过CE/RoHS认证,支持Modbus/USB通讯,专为紧凑场景设计,兼容DIN导轨安装,内置过压/欠流保护。

第三部分:产品详细说明

老司机聊聊这“小钢炮”的门道

某食品厂因普通变频器频繁进水故障,换它后连续运行3年未返厂。

真实使用逻辑:

自适应PID:恒压供水场景压力波动<±0.1MPa(传统方案为±0.5MPa);

节能算法:空载时自动降频,某厂年省电费8万。

GPD205-B003 MAGNETEK|技术规格(四列表格)

参数指标认证标准典型场景

效率94% 半载EN 61800-3小型冲床高响应调速

噪声≤50dB 50%负载UL 508E医疗设备静音运行

电磁兼容EN 55011 Class B IP54污水处理曝气机防潮防护

启动转矩150% 0Hz SIL2起重机零速抱闸

核心优势与性能亮点

电网抖动的“消防员”

某电子厂实测:电压骤降30%,电机转速波动<0.8%。

油污侵袭的“绝缘体”

环氧树脂灌封+疏油涂层,某石化厂反馈:五年未清洗内部。

调试参数的“自动化”

内置负载识别功能:某工程师1分钟完成水泵配置(传统需半天)。

应用场景

食品灌装线:防漏液控制——PID算法,液位误差<0.5mm;

纺织络筒机:断线保护——急停制动时间<0.2s;

实验室离心机:精密调速——0.1Hz阶梯变速;

化工计量泵:腐蚀防护——IP54+NEMA4X外壳;

半导体封装:微振动抑制——磁通矢量控制,0.001mm定位;

楼宇风机:节能模式——负荷<30%时自动休眠;

农业排灌:宽电压适配——100-240V全兼容;

电动叉车:频繁启停——IGBT模块寿命延长40%;

太阳能追踪器:极端温差——-20~60℃稳定运行;

3C装配线:群控同步——RS485组网,百台误差<0.1ms。

安装与维护建议

安装流程:

电源侧加装EMI滤波器(型号SN-EMI-240V);

通讯线屏蔽层单端接地(电阻≤0.5Ω);

散热片涂抹高导热脂(型号SN-COND-2W/mK)。

易错点提醒:

忘记设置载波频率(导致电机噪音大);

高湿环境未选配除湿加热器(型号SN-DEHUM-IP54)。

Part 1:SEO Optimized Title Generation(10 Total)

GPD205-B003 MAGNETEK-Small volume and large torque,the injection molding machine has low speed and no jitter!

GPD205-B003|2.2kW compact frequency converter+RS485 communication,precise speed control of machine tools

GPD205-B003 MAGNETEK-IP54 protection,no fear of water vapor in food processing

GPD205-B003-Overload 300%hard resistance,textile machinery line break rate decreases zero

GPD205-B003 MAGNETEK:Built-in energy-saving algorithm,air compressor saves 35%power

GPD205-B003-Fan expert,noise exceeds the standard?It directly reduces 10 decibels

GPD205-B003 MAGNETEK|Global certification,original authentic scan code traceability

GPD205-B003-Adaptive PID adjustment,chemical pump and valve pressure is as stable as a dog

GPD205-B003 MAGNETEK-Modular design,10 minutes hot plug and worry-free

GPD205-B003-Full communication protocol,the old factory renovation is in place in one step

Part 2:Brief description of the product

GPD205-B003 MAGNETEK:Miniature high-performance inverter,core parameters:rated power 2.2kW,input voltage 100-240V,protection level IP54.It adopts dual-core vector control+intelligent energy-saving algorithm,passes CE/RoHS certification,supports Modbus/USB communication,is designed for compact scenes,is compatible with DIN rail installation,and is built-in overvoltage/undercurrent protection.

Part 3:Product details

An experienced driver talks about the way of this”little steel cannon”

A food factory has frequently had water inflow failures due to ordinary frequency converters.After replacing it,it has been operated continuously for three years and has not returned to the factory.

Real usage logic:

Adaptive PID:The pressure fluctuation in constant pressure water supply scenario is<±0.1MPa(the traditional solution is±0.5MPa);

Energy-saving algorithm:automatically reduce frequency when no load,and a factory saves 80,000 yuan in electricity bills per year.

GPD205-B003 MAGNETEK|Technical Specifications(Four Lists)

Parameters Indicators Certification Standards Typical Scenarios

Efficiency 94% half load EN 61800-3 Small punch press high response speed regulation

Noise≤50dB 50%load UL 508E Medical equipment running silently

Electromagnetic compatibility EN 55011 Class B IP54 Sewage treatment aerator moisture protection

Starting torque 150% 0Hz SIL2 crane zero-speed brake

Core advantages and performance highlights

“Firefighters”shaking the power grid

An electronics factory measured that the voltage dropped by 30%,and the motor speed fluctuated by<0.8%.

“Insulator”attacked by oil pollution

Epoxy resin potting+oleophobic coating,feedback from a petrochemical plant:The interior has not been cleaned for five years.

“Automation”of debug parameters

Built-in load recognition function:An engineer completes the pump configuration in 1 minute(traditional ones take half a day).

Application scenarios

Food filling line:liquid leakage control-PID algorithm,liquid level error<0.5mm;

Textile winder:wire-break protection-emergency stop braking time<0.2s;

Laboratory centrifuge:precision speed regulation-0.1Hz step speed change;

Chemical metering pump:corrosion protection-IP54+NEMA4X housing;

Semiconductor package:micro vibration suppression—flux vector control,0.001mm positioning;

Building fan:Energy-saving mode—Automatic sleep when the load is less than 30%;

Agricultural drainage and irrigation:wide voltage adaptation—100-240V fully compatible;

Electric forklift:Frequent start and stop—the life of the IGBT module is extended by 40%;

Solar tracker:extreme temperature difference——-20~60℃stable operation;

3C assembly line:Group control synchronization-RS485 networking,with an error of 100 units<0.1ms.

Installation and maintenance suggestions

Installation process:

EMI filter is installed on the power supply side(model SN-EMI-240V);

Communication line shielding layer single-ended ground(resistance≤0.5Ω);

The heat sink is coated with high thermal grease(model SN-COND-2W/mK).

Reminder for easy mistakes:

Forgot to set the carrier frequency(causing high motor noise);

Dehumidifier heater(model SN-DEHUM-IP54)is not optional for high humidity environments.