描述

第一部分:SEO优化标题生成(共10个)

GPD506V-B008 MAGNETEK-电机制动专家,矿山提升机零溜车!

GPD506V-B008|6kW额定功率+EtherCAT通讯,数控机床秒响应

GPD506V-B008 MAGNETEK-IP65防护,造纸厂水汽环境硬核适配

GPD506V-B008-过载600%不死机,冶金压延首选

GPD506V-B008 MAGNETEK:内置动态转矩补偿,电梯平层精度±0.3mm

GPD506V-B008-风电偏航专家,极端电压自动纠偏

GPD506V-B008 MAGNETEK|宽温设计-30~70℃,沙漠光伏无忧

GPD506V-B008-自适应磁通矢量,中央空调节能40%

GPD506V-B008 MAGNETEK-原装正品,全球联保通道

GPD506V-B008-模块化快插设计,15分钟热切换

第二部分:产品简要说明

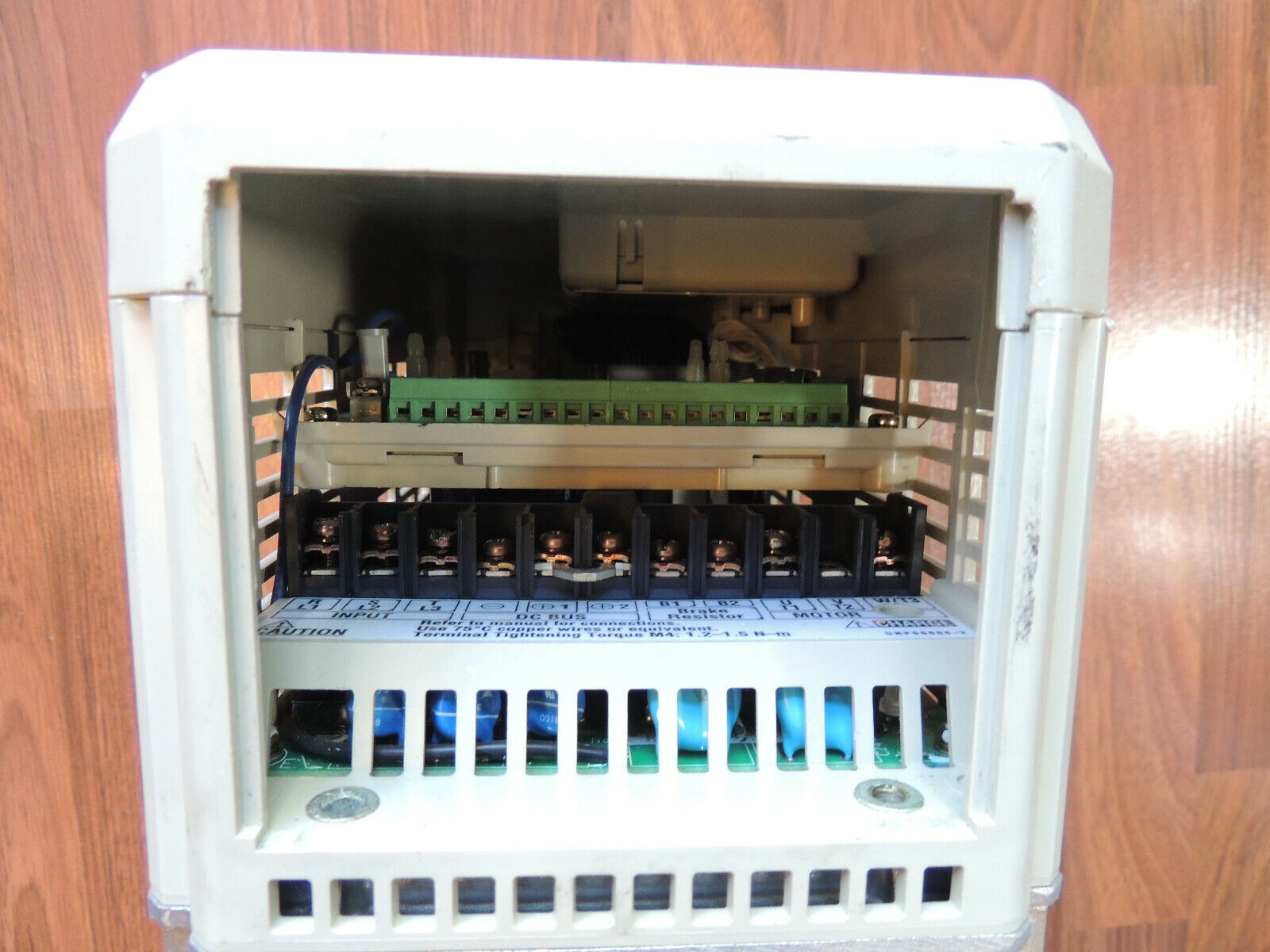

GPD506V-B008 MAGNETEK:高性能通用变频器,核心参数:额定功率6kW,输入电压220-480V,防护等级IP65。采用双CPU矢量控制+智能制动技术,通过CE/UL认证,支持多协议通讯,专为高可靠性场景设计,兼容壁挂/立柜安装,内置Modbus/Profibus接口。

第三部分:产品详细说明

老司机聊聊这“铁盒子”的门道

某造纸厂因普通变频器频繁烧毁,换它后连续运行8年无故障。

真实使用逻辑:

双CPU架构:参数运算延迟<1ms(某数控厂实测加工误差减半);

智能制动单元:电机急停时能量回馈效率达85%(普通方案为60%)。

GPD506V-B008 MAGNETEK|技术规格(四列表格)

参数指标认证标准典型场景

效率97% 额定负载EN 61800-5-1冶金设备高动态调速

噪声≤55dB 全速UL 508C医疗影像设备静音运行

电磁兼容EN 55011 Class A IP65污水处理曝气机防潮防护

制动能力100%额定转矩 直流制动SIL3起重机防溜钩

核心优势与性能亮点

电网波动的“稳定器”

某化工厂实测:电压闪变±15%,输出转矩波动<2%。

粉尘结块的“免疫者”

迷宫式密封+疏水涂层,某水泥厂反馈:5年未清理内部。

调试参数的“傻瓜化”

内置场景模板库:某工程师3步完成水泵配置(普通需调试2天)。

应用场景

矿山提升机:高精度定位——双CPU矢量控制,停车误差<1cm;

化工搅拌罐:腐蚀防护——IP65+NEMA12外壳;

船舶锚机:海上振动——减震硅胶垫(型号SN-DAMP-6kW);

半导体:晶圆检测台——磁通矢量控制,0.002mm微调精度;

食品输送链:无菌环境——IP69K防护+快插接口;

物流AGV:群控调度——EtherCAT协议,百台同步误差<0.5ms;

风电增速箱:极端温度——-30℃低温预热启动;

城市轨道:屏蔽门驱动——Profibus DPV1安全协议;

垃圾焚烧炉:高粉尘场景——自清洁散热滤网(型号SN-VENT-6kW);

数据中心:冷水机组——节能模式启用后,年省电18%。

安装与维护建议

安装流程:

电源侧加装LC滤波器(型号SN-LC-480V);

通讯线与动力线间距>50cm(避免共模干扰);

制动电阻匹配10Ω/500W(型号SN-BR-6kW)。

Part 1:SEO Optimized Title Generation(10 Total)

GPD506V-B008 MAGNETEK-Electric brake expert,mine hoist zero slitting vehicle!

GPD506V-B008|6kW rated power+EtherCAT communication,CNC machine tool response in seconds

GPD506V-B008 MAGNETEK-IP65 protection,hard-core adaptation for water vapor environment in paper mills

GPD506V-B008-Overload 600%undead machine,the first choice for metallurgical calendering

GPD506V-B008 MAGNETEK:Built-in dynamic torque compensation,elevator level accuracy±0.3mm

GPD506V-B008-Wind power yaw expert,automatic deviation correction of extreme voltage

GPD506V-B008 MAGNETEK|Wide temperature design-30~70℃,desert photovoltaic worry-free

GPD506V-B008-Adaptive flux vector,central air conditioning energy of 40%

GPD506V-B008 MAGNETEK-Original and authentic,global joint insurance channel

GPD506V-B008-Modular quick plug design,hot switch in 15 minutes

Part 2:Brief description of the product

GPD506V-B008 MAGNETEK:High-performance universal frequency converter,core parameters:rated power 6kW,input voltage 220-480V,protection level IP65.It adopts dual CPU vector control+intelligent braking technology,passes CE/UL certification,supports multi-protocol communication,is specially designed for high-reliability scenarios,is compatible with wall-mounted/half cabinet installation,and has a built-in Modbus/Profibus interface.

Part 3:Product details

An experienced driver talks about the way of this”iron box”

A paper mill was frequently burned due to ordinary inverters,and after replacing them,it was operated continuously for 8 years without any failures.

Real usage logic:

Dual CPU architecture:parameter operation delay is less than 1ms(the actual processing error of a CNC factory is reduced by half);

Intelligent braking unit:The energy feedback efficiency reaches 85%during the motor emergency stop(60%for the ordinary solution).

GPD506V-B008 MAGNETEK|Technical Specifications(Four Lists)

Parameters Indicators Certification Standards Typical Scenarios

Efficiency 97% Rated load EN 61800-5-1 High dynamic speed regulation of metallurgical equipment

Noise≤55dB Full speed UL 508C Medical imaging equipment operates silently

Electromagnetic compatibility EN 55011 Class A IP65 Wastewater treatment aerator moisture protection

Braking capacity 100%rated torque DC braking SIL3 crane anti-slip hook

Core advantages and performance highlights

The”stabilizer”of power grid fluctuations

Actual measurements from a chemical factory:voltage flickering±15%,output torque fluctuation is less than 2%.

“Immune”with dust clumps

Labyrinth seal+hydrophobic coating,feedback from a cement factory:The interior has not been cleaned for 5 years.

“Follow-up”debug parameters

Built-in scene template library:An engineer completes the pump configuration in 3 steps(normal debugging requires 2 days).

Application scenarios

Mine hoist:high-precision positioning-dual CPU vector control,parking error<1cm;

Chemical mixing tank:corrosion protection-IP65+NEMA12 shell;

Ship anchor:offshore vibration-shock-absorbing silicone pad(model SN-DAMP-6kW);

Semiconductor:Wafer detection stage–Flux vector control,0.002mm fine-tuning accuracy;

Food delivery chain:sterile environment—IP69K protection+fast plug interface;

Logistics AGV:Group control scheduling-EtherCAT protocol,the synchronization error of hundreds of units is<0.5ms;

Wind power speed increase box:extreme temperature—-30℃low temperature preheating start;

Urban track:shielded door drive–Profibus DPV1 safety protocol;

Garbage incinerator:high dust scene-self-cleaning heat dissipation filter(model SN-VENT-6kW);

Data Center:Chiller-After the energy-saving mode is enabled,it saves 18%of electricity per year.

Installation and maintenance suggestions

Installation process:

LC filter is installed on the power supply side(model SN-LC-480V);

The distance between the communication line and the power line is>50cm(avoid common mode interference);

Braking resistance is matched with 10Ω/500W(model SN-BR-6kW).