描述

产品简要说明

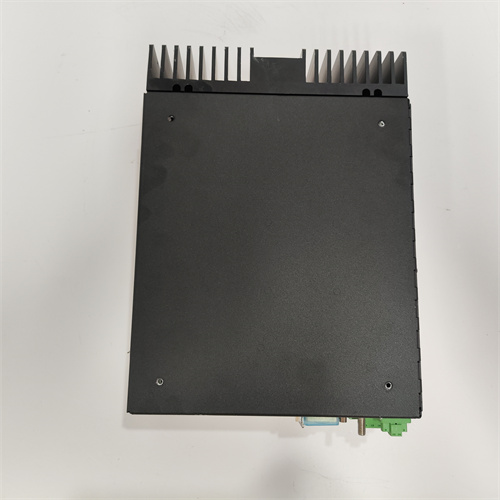

NEW GENUINE YASKAWA ETC620014-S019是一款专为工业电机驱动设计的高性能变频器,核心特性包括:

宽电压输入:支持100-480V AC输入,兼容全球电网标准

高效节能:IE4能效等级,功率因数≥0.99(满载时)

多协议通信:内置Modbus RTU、CANopen及EtherCAT协议栈

产品详细说明

1.核心技术架构

矢量控制技术:

采用无传感器矢量控制算法,动态响应时间≤10ms

支持转矩控制模式(TQC)与速度控制模式(SVC)切换

智能功率管理:

功率因数校正(PFC)技术,谐波含量<5%(THDi)

自适应负载识别功能,自动优化能效曲线

2.硬件设计亮点

散热结构:

双风扇强制风冷设计,噪音≤50dB(A)(满载运行)

工作温度范围-10℃至50℃(可选配高温散热套件)

防护等级:

IP55防护设计,适应油污、粉尘及轻度水雾环境

内置浪涌保护模块(耐受8/20μs脉冲,4kV)

技术规格:NEW GENUINE YASKAWA ETC620014-S019

参数项规格描述

额定功率75kW(3相,400V AC输入)

控制方式V/F控制、无传感器矢量控制、转矩控制

通信接口2×RS-485(Modbus RTU)、1×CANopen、1×EtherCAT

过载能力150%额定电流(1分钟)

防护等级IP55(可升级至IP65)

核心价值与性能亮点

1.节能优势

案例:在水泵系统中,通过变频调速使能耗降低30%(对比工频运行)。

2.工业级可靠性

优势:通过UL/CE/TUV认证,MTBF(平均无故障时间)≥50万小时。

3.智能诊断

功能:内置振动分析模块,可预测轴承故障并提前预警。

应对挑战,创造价值

1.高负载波动场景

方案:在轧机生产线中,通过转矩控制模式稳定输出扭矩±2%波动。

2.多协议协同控制

应用:支持EtherCAT主站与CANopen从站混合组网,适配自动化产线升级需求。

客户关注的焦点

安装规范:建议垂直安装以优化散热,底部预留≥50mm空间

参数配置:首次通电前需通过Yaskawa专用软件(GSDX)初始化参数

维护周期:每半年检查风扇滤网清洁度,防止积尘影响散热效率

Product brief description

NEW GENUINE YASKAWA ETC620014-S019 is a high-performance frequency converter designed for industrial motor drives.The core features include:

Wide voltage input:Supports 100-480V AC input,compatible with global power grid standards

High efficiency and energy saving:IE4 energy efficiency level,power factor≥0.99(at full load)

Multi-protocol communication:built-in Modbus RTU,CANopen and EtherCAT protocol stack

Product details

1.Core technology architecture

Vector control technology:

Using sensorless vector control algorithm,dynamic response time≤10ms

Supports switching between torque control mode(TQC)and speed control mode(SVC)

Intelligent power management:

Power factor correction(PFC)technology,harmonic content<5%(THDi)

Adaptive load recognition function,automatic optimization of energy efficiency curve

2.Highlights of hardware design

Heat dissipation structure:

Dual fan forced air cooling design,noise≤50dB(A)(full load operation)

Operating temperature range-10℃to 50℃(optional high temperature heat dissipation kit)

Protection level:

IP55 protection design,adapts to oil,dust and light water mist environments

Built-in surge protection module(with 8/20μs pulses,4kV)

Technical Specifications:NEW GENUINE YASKAWA ETC620014-S019

Parameters Specification Description

Rated power 75kW(3 phases,400V AC input)

Control mode V/F control,sensorless vector control,torque control

Communication interface 2×RS-485(Modbus RTU),1×CANopen,1×EtherCAT

Overload capacity 150%rated current(1 minute)

Protection level IP55(can be upgraded to IP65)

Core Valuesand Performance Highlights

1.Energy saving advantages

Case:In the water pump system,energy consumption is reduced by 30%through frequency conversion speed regulation(compared with power frequency operation).

2.Industrial-grade reliability

Advantages:Passed UL/CE/TUV certification,MTBF(average failure-free time)≥500,000 hours.

3.Intelligent Diagnosis

Function:Built-in vibration analysis module,can predict bearing failures and early warning.

Respond to challenges and create value

1.High load fluctuation scenario

Solution:In the rolling mill production line,the output torque fluctuation is stabilized through the torque control mode.

2.Multi-protocol collaborative control

Application:Supports hybrid networking between EtherCAT master and CANopen slaves,adapts to the upgrade requirements of automated production lines.

Customer focus

Installation specifications:vertical installation is recommended to optimize heat dissipation,and≥50mm space is reserved at the bottom.

Parameter configuration:Before the first power-on,the parameters must be initialized through Yaskawa special software(GSDX)

Maintenance cycle:Check the cleanliness of the fan filter every six months to prevent dust accumulation and affect the heat dissipation efficiency