描述

产品简要说明

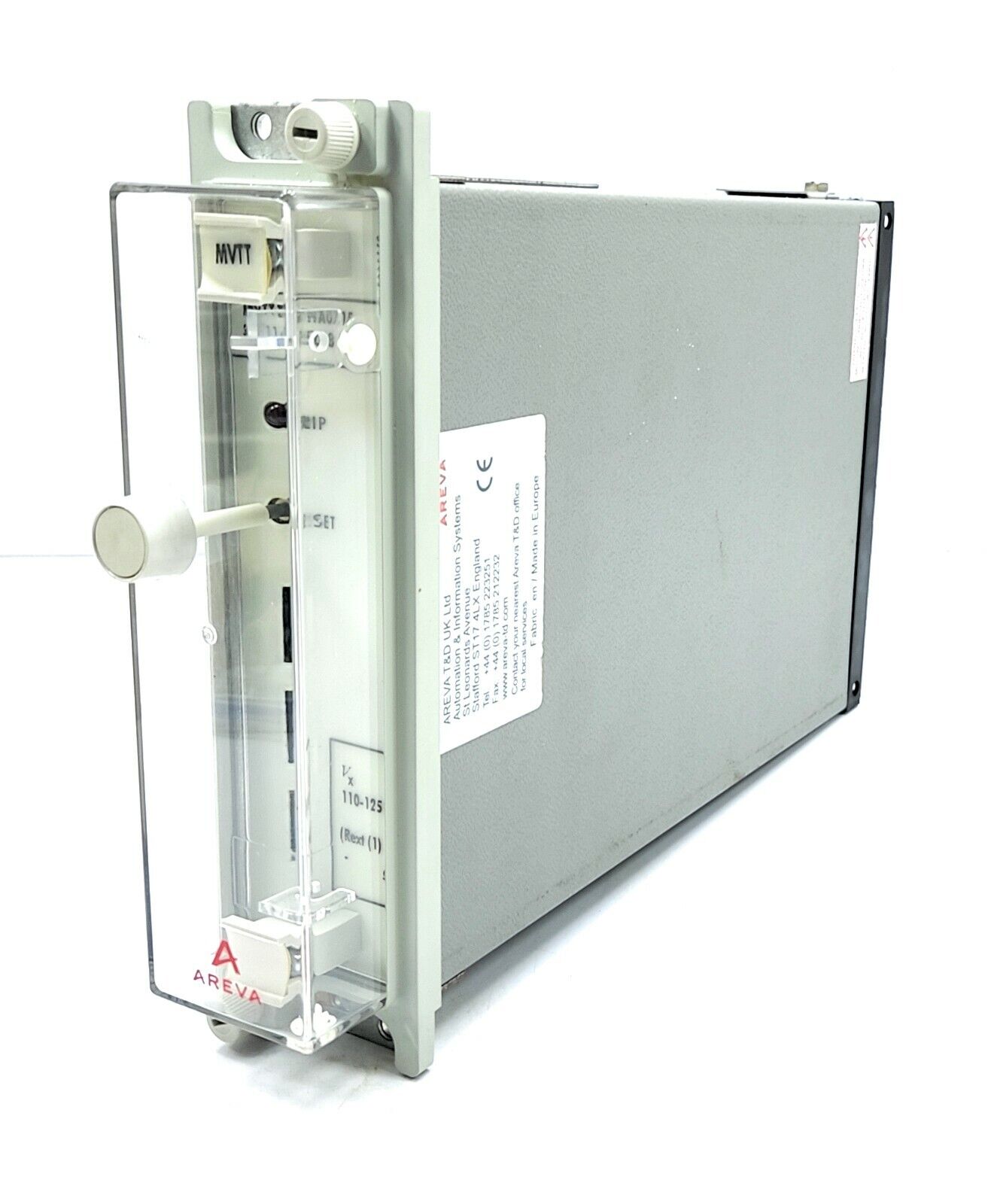

ASML 859-8739-001 PCB是ASML光刻机(如EUV系列)的核心控制电路板,专为极端环境下的高精度信号传输设计。其核心功能包括:

多层信号整合:支持16层以上高密度互连(HDI)结构,实现亚微米级线宽控制。

抗干扰设计:集成磁屏蔽层与差分信号传输技术,EMC等级达IEC 61000-6-4。

极端环境适配:耐受-40℃至125℃温度波动,湿度范围5%-95%(无冷凝)。

产品详细说明

1.技术架构与创新

材料体系:

基材:采用聚酰亚胺(PI)与玻璃纤维复合材料,介电常数稳定在3.5±0.1。

导电层:99.99%纯度铜箔,表面粗糙度Ra≤0.8μm,确保高频信号完整性。

制造工艺:

激光钻孔:微盲孔直径≤50μm,孔壁粗糙度Ra≤1.5μm。

阻焊膜:采用液态光致阻焊剂(LPI),附着力≥2.0N/cm(划格法测试)。

2.工艺适配性

光刻机控制场景:

运动控制:支持纳米级步进台定位信号传输(延迟<10ns)。

能量管理:集成高精度电源分配网络(PDN),纹波抑制比>60dB。

环境适应性:

振动抑制:采用压电陶瓷主动减震技术,10-1000Hz频段振动衰减>30dB。

洁净度控制:表面颗粒污染≤0.1μm(Class 100洁净室标准)。

3.行业标准遵循

环保与安全:

ISO 14001:生产废水处理达标率100%,废气净化效率≥99.5%。

UL 94 V-0:阻燃等级符合最高安全标准,燃烧速率≤40mm/min。

制造规范:

IPC-600J:焊盘缺陷控制(中心80%区域无铜瘤/针孔),阻焊膜偏移≤±50μm。

IPC-6012D:线宽/间距公差±10%,孔环尺寸公差±15μm。

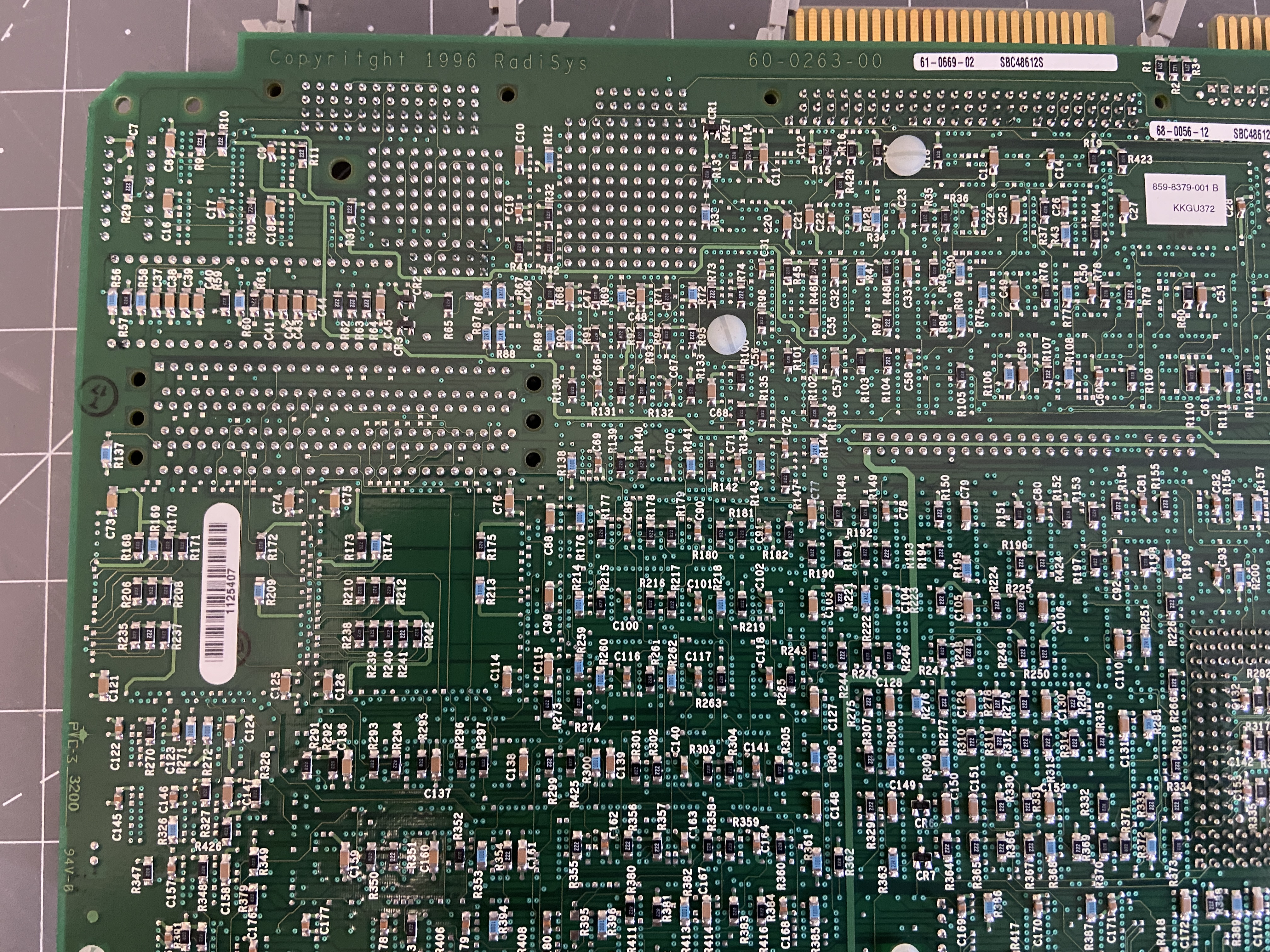

技术规格:ASML 859-8739-001

参数项规格描述

层数16层HDI

线宽/间距3/3μm(最小值)

工作温度-40℃至125℃

尺寸300mm×200mm×3.2mm

核心价值与性能亮点

1.极端环境可靠性

热管理:内置热电偶阵列实时监测,温度梯度控制≤0.5℃/cm²。

化学稳定性:耐受光刻胶残留物(如SU-8)腐蚀,表面电阻率≥1×10^12Ω。

2.信号完整性保障

阻抗控制:差分线阻抗50±2Ω,单端线阻抗100±5Ω。

抗串扰设计:相邻信号线耦合系数<5%,时序偏差

Product brief description

ASML 859-8739-001 PCB is the core control circuit board of ASML lithography machines(such as the EUV series),designed for high-precision signal transmission in extreme environments.Its core functions include:

Multi-layer signal integration:supports high-density interconnection(HDI)structures above 16 layers to realize submicron-level linewidth control.

Anti-interference design:integrated magnetic shielding layer and differential signal transmission technology,with an EMC level of IEC 61000-6-4.

Extreme environmental adaptation:Tolerate temperature fluctuations between-40℃and 125℃,humidity range of 5%-95%(no condensation).

Product details

1.Technical Architecture and Innovation

Material system:

Base material:Polyimide(PI)and glass fiber composite material are used,and the dielectric constant is stable at 3.5±0.1.

Conductive layer:99.99%purity copper foil,surface roughness Ra≤0.8μm,ensuring high-frequency signal integrity.

Manufacturing process:

Laser drilling:the diameter of the microblind hole is≤50μm,and the hole wall roughness Ra≤1.5μm.

Solder resist film:Liquid photoresist(LPI)is used,with adhesion≥2.0N/cm(scribing test).

2.Process adaptability

Lithography machine control scenario:

Motion control:Supports nano-level stepping stage positioning signal transmission(delay<10ns).

Energy management:Integrated high-precision power distribution network(PDN),ripple suppression ratio>60dB.

Environmental adaptability:

Vibration suppression:Use piezoelectric ceramic active shock absorption technology,and the vibration attenuation of the 10-1000Hz frequency band is>30dB.

Cleanliness control:Surface particle pollution≤0.1μm(Class 100 clean room standard).

3.Industry standards comply with

Environmental protection and safety:

ISO 14001:The production wastewater treatment compliance rate is 100%,and the waste gas purification efficiency is≥99.5%.

UL 94 V-0:The flame retardant grade meets the highest safety standards,and the combustion rate is≤40mm/min.

Manufacturing specifications:

IPC-600J:pad defect control(no copper tumor/pinhole in 80%of the center),solder resist film offset≤±50μm.

IPC-6012D:Line width/pad tolerance±10%,hole ring size tolerance±15μm.

Technical Specifications:ASML 859-8739-001

Parameters Specification Description

Number of layers 16 layers HDI

Line width/pitch 3/3μm(minimum)

Operating temperature-40℃to 125℃

Dimensions 300mm×200mm×3.2mm

Core Valuesand Performance Highlights

1.Extreme environmental reliability

Thermal management:built-in thermocouple array is monitored in real time,and the temperature gradient control is≤0.5℃/cm².

Chemical stability:Tolerate corrosion of photoresist residues(such as SU-8),surface resistivity≥1×10^12Ω.

2.Signal integrity guarantee

Impedance control:differential line impedance is 50±2Ω,single-ended line impedance is 100±5Ω.

Anti-crosstalk design:the coupling coefficient of adjacent signal lines is<5%,timing deviation is<1ps.