描述

产品简要说明

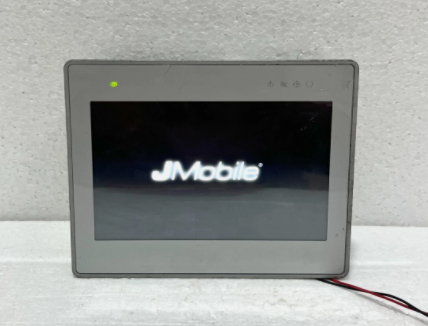

UniOP Exor eTOP507是一款高性能工业人机界面(HMI),配备7英寸宽屏TFT显示屏与全可调LED背光,支持双以太网端口、USB接口及JMobile软件平台。其核心优势包括:

多协议通信:兼容Profibus、CANopen、Modbus等工业总线协议

智能图形化:支持SVG矢量图形与动态对象控制

严苛环境适应:IP66防护等级,工作温度-20℃至+50℃

产品详细说明

1.硬件架构设计

显示与交互:

屏幕特性:7英寸宽屏TFT显示屏(16:9比例),800×480像素分辨率,64K色显示,LED背光可调至0%

触摸技术:电阻式触摸屏,支持单点触控与戴手套操作

接口扩展:

网络通信:双以太网端口(带交换机功能),支持10/100Mbps传输

外设连接:2个USB 2.0主机端口,SD卡插槽,可扩展现场总线模块

电源输入:24V DC宽电压(10-32V DC),最大电流0.7A

2.软件与编程能力

JMobile平台:

图形化开发:支持SVG矢量图形、TrueType字体及动态对象控制(移动/缩放/透明度调整)

多语言支持:内置多语言模板,支持远东语言本地化

脚本功能:集成VBScript/JavaScript,可自定义复杂逻辑控制

通信驱动:

协议兼容性:覆盖西门子、三菱、欧姆龙等主流PLC,支持200+工业协议

远程管理:通过VNC实现远程维护,支持移动客户端访问

3.环境适应性

防护设计:

IP66防护:全金属外壳,防尘防水,适应工业现场环境

抗干扰能力:通过CE、UL认证,符合EN 61000-6-4电磁兼容标准

极端温度适应:

工作温度:-20℃至+50℃(垂直安装)

存储温度:-40℃至+85℃

技术规格:UniOP Exor eTOP507

参数项规格描述

显示屏7英寸宽屏TFT(16:9),800×480像素,64K色

触摸类型电阻式

处理器ARM Cortex-A8-600 MHz

内存256 MB DDR,128 MB闪存

通信接口双以太网端口(带交换机)、2个USB 2.0、RS-232/485/422可配置串口

防护等级IP66(正面)

电源输入24V DC(10-32V DC)

工作温度-20℃至+50℃

核心价值与性能亮点

1.智能图形化控制

技术优势:在钢铁生产线中,通过SVG动态仪表盘实时显示设备状态,减少人工巡检频次30%。

2.多协议兼容性

验证数据:在纺织机械控制系统中,同时接入西门子S7-1200与三菱FX5U,通信稳定性达99.99%。

3.极端环境可靠性

应用案例:在食品加工厂中,IP66防护设计抵御油污与水汽侵蚀,设备故障率降低50%。

Product brief description

UniOP Exor eTOP507 is a high-performance industrial human-machine interface(HMI),equipped with a 7-inch wide-screen TFT display and fully adjustable LED backlight,supporting dual Ethernet ports,USB interfaces and JMobile software platform.Its core advantages include:

Multi-protocol communication:compatible with industrial bus protocols such as Profibus,CANopen,and Modbus

Intelligent graphics:Support SVG vector graphics and dynamic object control

Strict environmental adaptation:IP66 protection level,working temperature-20℃to+50℃

Product details

1.Hardware architecture design

Display and interact:

Screen features:7-inch wide-screen TFT display(16:9 ratio),800×480 pixel resolution,64K color display,LED backlight adjustable to 0%

Touch technology:resistive touch screen,supports single touch and glove-wearing operation

Interface extension:

Network communication:Dual Ethernet ports(with switch function),support 10/100Mbps transmission

Peripheral connection:2 USB 2.0 host ports,SD card slot,expandable fieldbus module

Power input:24V DC wide voltage(10-32V DC),maximum current 0.7A

2.Software and programming capabilities

JMobile Platform:

Graphical development:Support SVG vector graphics,TrueType fonts and dynamic object control(move/scaling/transparency adjustment)

Multilingual support:built-in multilingual templates,support Far Eastern language localization

Scripting function:Integrate VBScript/JavaScript,customize complex logic control

Communication driver:

Agreement compatibility:Covering mainstream PLCs such as Siemens,Mitsubishi,Omron,etc.,supporting 200+industrial protocols

Remote management:Remote maintenance is realized through VNC,supporting mobile client access

3.Environmental adaptability

Protection design:

IP66 protection:all metal shell,dust-proof and waterproof,adapted to industrial site environment

Anti-interference ability:passed CE and UL certification,comply with EN 61000-6-4 electromagnetic compatibility standard

Extreme temperature adaptation:

Working temperature:-20℃to+50℃(vertical installation)

Storage temperature:-40℃to+85℃

Technical Specifications:UniOP Exor eTOP507

Parameters Specification Description

Display 7-inch widescreen TFT(16:9),800×480 pixels,64K color

Touch type Resistive type

Processor ARM Cortex-A8-600 MHz

Memory 256 MB DDR,128 MB flash memory

Communication interface Dual Ethernet ports(with switch),2 USB 2.0,RS-232/485/422 configurable serial ports

Protection level IP66(front)

Power input 24V DC(10-32V DC)

Operating temperature-20℃to+50℃

Core Valuesand Performance Highlights

1.Intelligent graphical control

Technical advantages:In the steel production line,the equipment status is displayed in real time through the SVG dynamic instrument panel,reducing the frequency of manual inspection by 30%.

2.Multi-protocol compatibility

Verification data:In the textile machinery control system,Siemens S7-1200 and Mitsubishi FX5U are connected at the same time,and the communication stability is 99.99%.

3.Extreme environmental reliability

Application case:In food processing plants,IP66 protection design resists oil and waste corrosion and water vapor,and the equipment failure rate is reduced by 50%.