描述

产品简要说明

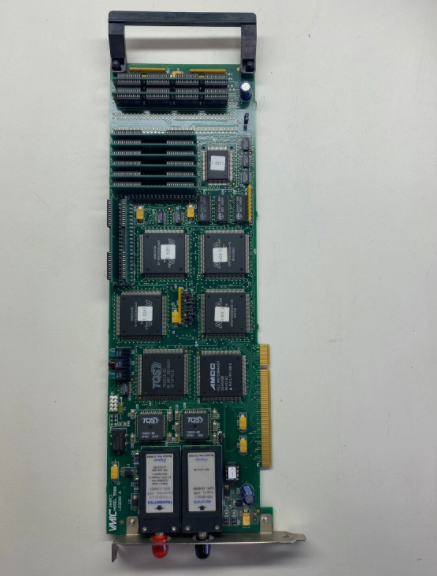

VMIPCI 5588-101是通用电气(GE)开发的工业控制PCI扩展卡,专为工业自动化系统、数据采集与高速通信设计。其核心特性包括:

多协议兼容:支持EtherCAT、Profinet、Modbus-TCP等工业网络协议

高精度数据采集:16位分辨率,采样率最高达1MHz

硬件加速:基于FPGA的实时数据处理,降低CPU负载

工业级防护:符合IP67防护等级与宽温域设计(-40℃~+70℃)

产品详细说明

1.核心功能架构

硬件设计

处理器架构:

主控芯片:Xilinx Artix-7 FPGA(28nm工艺)

辅助处理器:ARM Cortex-M4(200MHz主频)

存储配置:

DDR3 SDRAM:512MB(用于缓存与实时数据处理)

Flash存储:128MB(固件与用户配置存储)

通信接口

工业网络接口:

2×EtherCAT(支持主站/从站模式)

1×Profinet(实时RT模式)

1×Modbus-TCP(兼容Modbus RTU协议转换)

I/O通道:

数字I/O:32通道(支持隔离/非隔离配置)

模拟I/O:16通道(±10V量程,16位分辨率)

数据处理能力

实时性保障:

任务调度:基于FPGA的硬件级实时任务队列

延迟控制:数据传输延迟≤50μs(EtherCAT模式)

协议栈优化:

嵌入式协议处理引擎,减少主CPU负载

产品概述:VMIPCI 5588-101

作为GE工业自动化接口解决方案的核心模块,其核心价值在于多协议融合与高速数据处理:

技术价值:

在风电SCADA系统中,实现100节点EtherCAT网络实时监控

在数控机床中,支持1MHz采样率刀具磨损检测

行业适配:

能源电力:风电场数据采集、变电站保护装置

智能制造:CNC机床状态监测、工业机器人轨迹反馈

轨道交通:列车控制系统信号处理、车载传感器数据聚合

技术规格:VMIPCI 5588-101

参数项规格描述

处理器Xilinx Artix-7 FPGA+ARM Cortex-M4(200MHz)

存储DDR3 SDRAM 512MB+Flash 128MB

通信接口2×EtherCAT、1×Profinet、1×Modbus-TCP

I/O通道数字I/O 32通道(隔离/非隔离可选)、模拟I/O 16通道(±10V/16位)

工作温度-40℃~+70℃(工业级宽温设计)

核心价值与性能亮点

1.多协议并行处理

技术优势:单卡集成EtherCAT、Profinet、Modbus-TCP三协议栈

应用案例:某汽车工厂通过该模块实现PLC、机器人与视觉系统协同控制

2.硬件加速数据采集

技术优势:FPGA实时数据处理,CPU负载降低至10%以下

行业应用:在风电变桨系统中,实现1MHz采样率振动监测

3.工业级可靠性

技术优势:IP67防护+宽温设计,通过振动测试(MIL-STD-810G)

价值体现:某化工厂设备在-30℃环境中连续运行5年零故障

Product brief description

VMIPCI 5588-101 is an industrial control PCI expansion card developed by General Electric(GE),designed for industrial automation systems,data acquisition and high-speed communications.Its core features include:

Multi-protocol compatibility:supports industrial network protocols such as EtherCAT,Profinet,Modbus-TCP

High-precision data acquisition:16-bit resolution,sampling rate up to 1MHz

Hardware acceleration:FPGA-based real-time data processing to reduce CPU load

Industrial protection:Comply with IP67 protection grade and wide temperature range design(-40℃~+70℃)

Product details

1.Core functional architecture

Hardware design

Processor architecture:

Main control chip:Xilinx Artix-7 FPGA(28nm process)

Auxiliary processor:ARM Cortex-M4(200MHz main frequency)

Storage configuration:

DDR3 SDRAM:512MB(for cache and real-time data processing)

Flash storage:128MB(firmware and user configuration storage)

Communication interface

Industrial network interface:

2×EtherCAT(supports master/slave mode)

1×Profinet(real-time RT mode)

1×Modbus-TCP(compatible with Modbus RTU protocol conversion)

I/O channel:

Digital I/O:32 channels(supports isolation/non-isolated configuration)

Analog I/O:16 channels(±10V range,16-bit resolution)

Data processing capability

Real-time guarantee:

Task Scheduling:Hardware-level real-time task queue based on FPGA

Delay control:data transmission delay≤50μs(EtherCAT mode)

Protocol stack optimization:

Embedded protocol processing engine to reduce main CPU load

Product Overview:VMIPCI 5588-101

As the core module of GE’s industrial automation interface solution,its core value lies in multi-protocol fusion and high-speed data processing:

Technical value:

In the wind power SCADA system,real-time monitoring of 100 node EtherCAT network is realized

In CNC machine tools,1MHz sampling rate tool wear detection is supported

Industry adaptation:

Energy and electricity:wind farm data acquisition,substation protection device

Intelligent manufacturing:CNC machine tool status monitoring,industrial robot trajectory feedback

Rail Transit:signal processing of train control system,vehicle-mounted sensor data aggregation

Technical Specifications:VMIPCI 5588-101

Parameters Specification Description

Processor Xilinx Artix-7 FPGA+ARM Cortex-M4(200MHz)

Storage DDR3 SDRAM 512MB+Flash 128MB

Communication interface 2×EtherCAT,1×Profinet,1×Modbus-TCP

I/O channel Digital I/O 32 channel(isolated/non-isolated optional),analog I/O 16 channel(±10V/16 bit)

Working temperature-40℃~+70℃(industrial-grade wide temperature design)

Core Valuesand Performance Highlights

1.Multi-protocol parallel processing

Technical advantages:Single card integrated three protocol stacks of EtherCAT,Profinet,and Modbus-TCP

Application case:A certain automobile factory realizes coordinated control of PLC,robot and vision system through this module

2.Hardware-accelerated data acquisition

Technical advantages:FPGA real-time data processing,and the CPU load is reduced to less than 10%.

Industry application:In wind power pitch system,1MHz sampling rate vibration monitoring is realized

3.Industrial reliability

Technical advantages:IP67 protection+wide temperature design,passing vibration test(MIL-STD-810G)

Value manifestation:Equipment in a chemical plant operates continuously for 5 years in an environment of-30℃.