描述

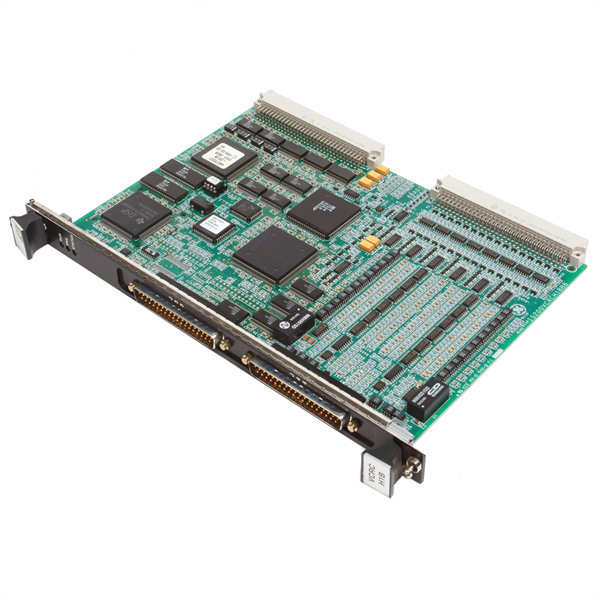

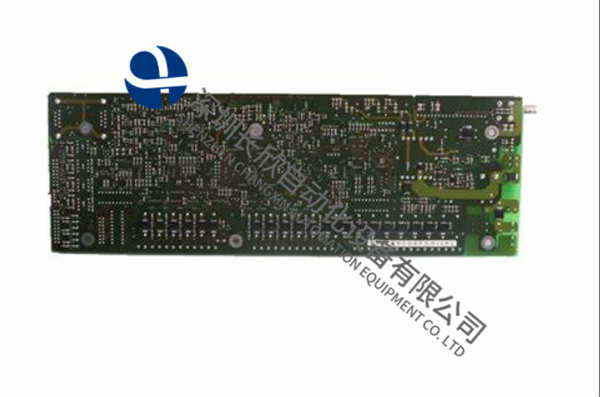

KOLLMORGEN S70602-NANANA伺服电机控制器技术数据解析

一、核心功能与性能

高性能运动控制

支持高精度轨迹、速度和位置控制,适用于自动化生产线、机械加工及装配系统等场景。

通过硬PLC架构实现快速响应,优化运动控制逻辑。

多轴协调控制

支持多轴同步运动,适用于机械臂、传送线等复杂协调控制需求。

二、接口与通信

物理接口

数字I/O:支持20524点硬PLC I/O,可扩展控制信号输入输出。

模拟I/O:未明确标注具体通道数,但支持模拟信号处理。

通信协议

以太网:支持工业以太网协议(如EtherCAT、Profinet)。

总线接口:兼容CAN总线、Profibus等工业通信协议。

三、控制与编程能力

可编程逻辑

支持自定义运动控制算法,可通过编程实现复杂逻辑(如轨迹规划、闭环反馈)。

兼容硬PLC指令集,适用于实时控制任务。

模块化扩展

支持扩展模块(如驱动器、传感器接口),提升系统灵活性。

四、环境与可靠性

工作环境

温度范围:未明确标注,但适用于工业级恶劣环境(推测为-20°C至+70°C)。

防护等级:未明确,但支持抗振动、防尘设计。

稳定性与安全

冗余电源设计,支持故障诊断与保护功能(如过流、过压)。

支持热插拔维护,减少停机时间。

五、应用场景

工业自动化

机械臂控制、CNC机床、装配线等高精度运动场景。

能源与制造

新能源设备(如太阳能跟踪系统)、精密加工设备。

CB06551 PRD-B040SSIB-63

CB06551 PRD-B040SSIB-63

KOLLMORGEN S70602-NANANA Servo motor controller technical data analysis

1.Core functions and performance

High performance motion control

Supports high-precision trajectory,speed and position control,and is suitable for scenarios such as automated production lines,mechanical processing and assembly systems.

Fast response is achieved through hard PLC architecture and optimize motion control logic.

Multi-axis coordination control

Supports multi-axis synchronous motion,suitable for complex coordinated control needs such as robotic arms and transmission lines.

2.Interface and communication

Physical interface

Digital I/O:Supports 20524-point hard PLC I/O,and can expand the control signal input and output.

Analog I/O:The specific number of channels is not clearly marked,but analog signal processing is supported.

Communication Protocol

Ethernet:supports industrial Ethernet protocols(such as EtherCAT,Profinet).

Bus interface:compatible with industrial communication protocols such as CAN bus and Profibus.

3.Control and programming capabilities

Programmable logic

Supports custom motion control algorithms,and can implement complex logic(such as trajectory planning,closed-loop feedback)through programming.

Compatible with hard PLC instruction sets,suitable for real-time control tasks.

Modular extension

Supports expansion modules(such as drivers and sensor interfaces)to improve system flexibility.

IV.Environment and Reliability

Working environment

Temperature range:Not clearly marked,but suitable for industrial-grade harsh environments(presumably-20°C to+70°C).

Protection level:Not clear,but supports vibration-resistant and dust-resistant design.

Stability and safety

Redundant power supply design,supporting fault diagnosis and protection functions(such as overcurrent and overvoltage).

Supports hot-swap maintenance to reduce downtime.

5.Application scenarios

Industrial automation

High-precision motion scenarios such as robotic arm control,CNC machine tools,assembly lines,etc.

Energy and Manufacturing

New energy equipment(such as solar tracking systems),precision processing equipment.