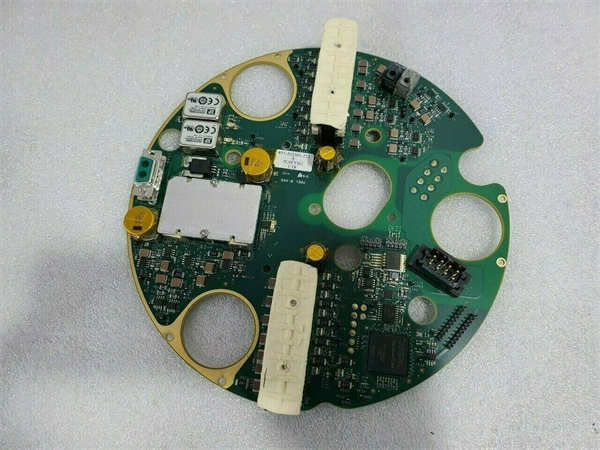

描述

产品简要说明

Metso D200534是一款工业级可编程逻辑控制器(PLC),核心功能包括:

多协议兼容:支持Modbus、EtherCAT、Profinet等工业通信协议

边缘计算能力:内置实时数据处理引擎,支持本地化逻辑控制

工业级防护:IP68防护等级,耐受-50°C至70°C极端温度

冗余设计:双电源输入+双CPU冗余,故障自恢复时间≤200ms

产品详细说明

1.技术架构与核心功能

协议兼容性:

协议栈集成:支持Modbus RTU/TCP、EtherCAT、Profinet、OPC UA UA等协议

协议转换:跨协议数据映射(如将EtherCAT信号转换为Modbus指令)

通信优化:采用光纤通信技术,传输距离达500米(支持单模光纤)

控制架构:

双CPU冗余:主从CPU协同工作,主CPU故障时从CPU无缝接管(切换时间≤20ms)

实时控制:支持2ms扫描周期,最大I/O点数1024点

数据存储:4GB DDR4内存+32GB eMMC存储,支持工业级数据日志

2.工业环境适配性

极端温度管理:

相变材料散热:采用石蜡基相变材料,70°C环境下温升≤10°C

低温启动:内置电加热膜,-50°C环境下启动时间≤45秒

抗腐蚀设计:

外壳材质:316L不锈钢外壳,耐酸碱腐蚀(符合ASTM A240标准)

密封技术:O型圈双重密封,防水等级IP68(水深3米,24小时)

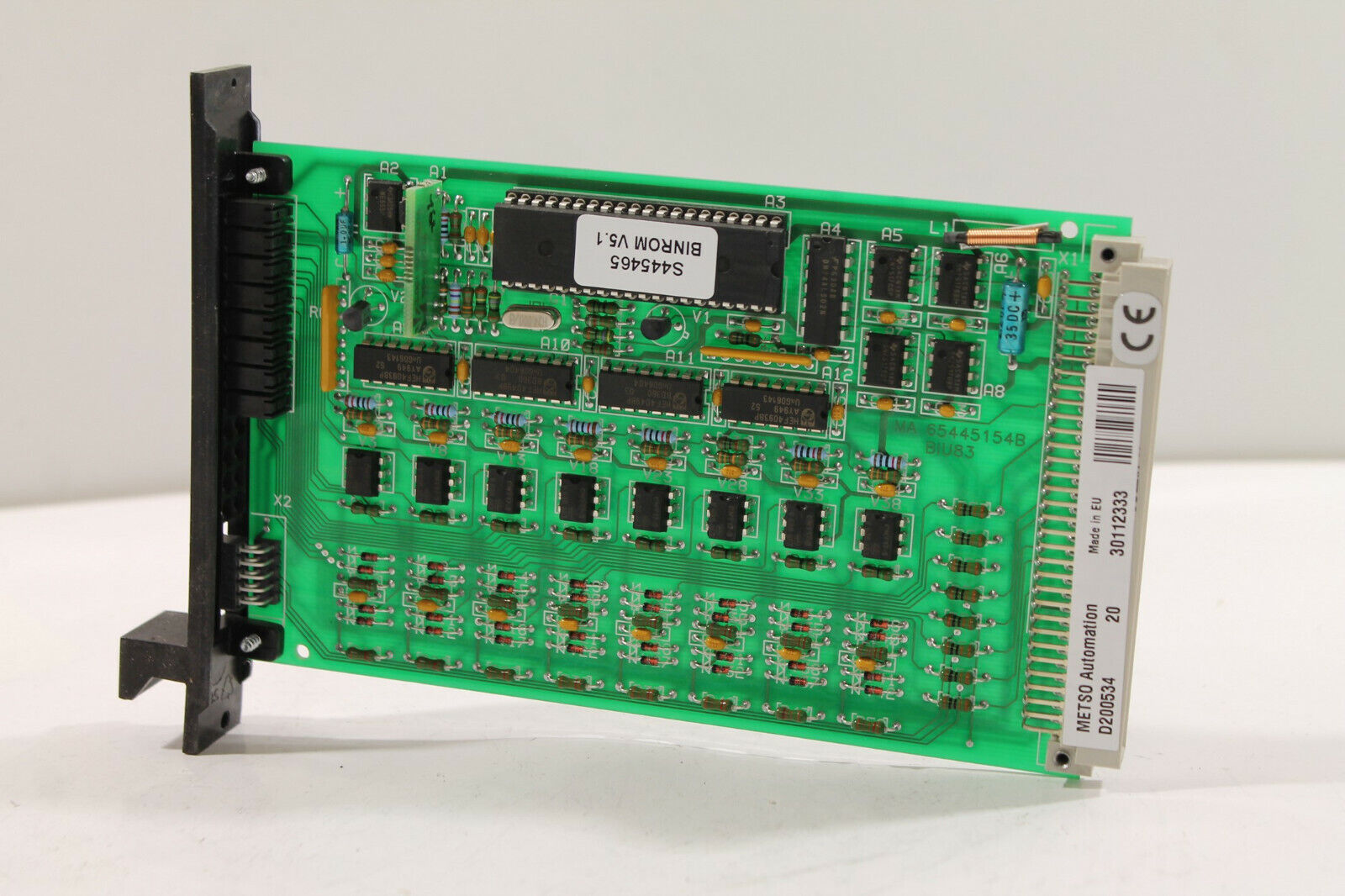

技术规格:Metso D200534

参数项规格描述

处理器NXP i.MX 8X Ultra(四核Cortex-A53,主频2GHz)

存储配置4GB DDR4+32GB eMMC(支持NVMe SSD扩展)

通信接口4×Gigabit Ethernet(支持PoE++)、2×4G LTE、1×RS485

防护等级IP68(防尘防水)

工作温度-50℃至70℃

电源输入24V DC(冗余双路供电,支持宽电压18-36V)

I/O点数16×DI+8×DO(可扩展至1024点)

核心价值与性能亮点

1.高可靠性控制

技术突破:某石油平台部署D200534后,设备控制故障率降低50%(因冗余设计避免单点故障)

2.复杂系统集成

场景适配:在化工厂中,同时连接DCS系统与现场传感器,协议转换延迟≤1ms

应对挑战,创造价值

1.严苛环境可靠性

技术突破:某极地科考站使用D200534后,设备在-50°C环境中连续运行3个月无故障

2.多协议系统整合

场景案例:港口自动化系统通过D200534实现PLC与SCADA系统无缝对接,集成周期缩短40%

Product brief description

Metso D200534 is an industrial-grade programmable logic controller(PLC),with core functions including:

Multi-protocol compatibility:supports industrial communication protocols such as Modbus,EtherCAT,Profinet

Edge computing capability:built-in real-time data processing engine,supporting localized logic control

Industrial protection:IP68 protection rating,withstand extreme temperatures-50°C to 70°C

Redundant design:dual power input+dual CPU redundancy,fault self-recovery time≤200ms

Product details

1.Technical architecture and core functions

Protocol Compatibility:

Protocol stack integration:Supports Modbus RTU/TCP,EtherCAT,Profinet,OPC UA UA and other protocols

Protocol conversion:cross-protocol data mapping(such as converting EtherCAT signals to Modbus instructions)

Communication optimization:adopts optical fiber communication technology,with a transmission distance of up to 500 meters(supports single-mode optical fiber)

Control architecture:

Dual CPU redundancy:Master and slave CPU work together,and the slave CPU seamlessly connects to the slave CPU when the master CPU fails(switching time≤20ms)

Real-time control:Supports 2ms scanning cycle,maximum I/O points 1024 points

Data storage:4GB DDR4 memory+32GB eMMC storage,support industrial-grade data logs

2.Industrial environment adaptability

Extreme temperature management:

Heat dissipation of phase change materials:Paraffin-based phase change materials are used,and the temperature rise is≤10°C under 70°C environment

Low temperature start:built-in electric heating film,start time≤45 seconds under-50°C environment

Corrosion-resistant design:

Housing material:316L stainless steel housing,acid and alkali corrosion resistant(compliant with ASTM A240 standard)

Sealing technology:O-ring double seal,waterproof grade IP68(water depth 3 meters,24 hours)

Technical Specifications:Metso D200534

Parameters Specification Description

Processor NXP i.MX 8X Ultra(quad-core Cortex-A53,main frequency 2GHz)

Storage configuration 4GB DDR4+32GB eMMC(supports NVMe SSD extension)

Communication interface 4×Gigabit Ethernet(supports PoE++),2×4G LTE,1×RS485

Protection level IP68(dust-proof and waterproof)

Operating temperature-50℃to 70℃

Power input 24V DC(redundant dual power supply,support wide voltage 18-36V)

I/O points 16×DI+8×DO(scalable to 1024 points)

Core Valuesand Performance Highlights

1.High reliability control

Technical breakthrough:After a certain oil platform deploys D200534,the equipment control failure rate is reduced by 50%(single-point failure is avoided due to redundant design)

2.Complex system integration

Scenario adaptation:In a chemical factory,the DCS system and the on-site sensor are connected at the same time,and the protocol conversion delay is≤1ms

Respond to challenges and create value

1.Strict environmental reliability

Technical breakthrough:After a polar scientific research station uses D200534,the equipment operates continuously in-50°C environment for 3 months without any troubles

2.Multi-protocol system integration

Scenario case:The port automation system achieves seamless connection between PLC and SCADA system through D200534,and the integration cycle is shortened by 40%.