描述

产品简要说明

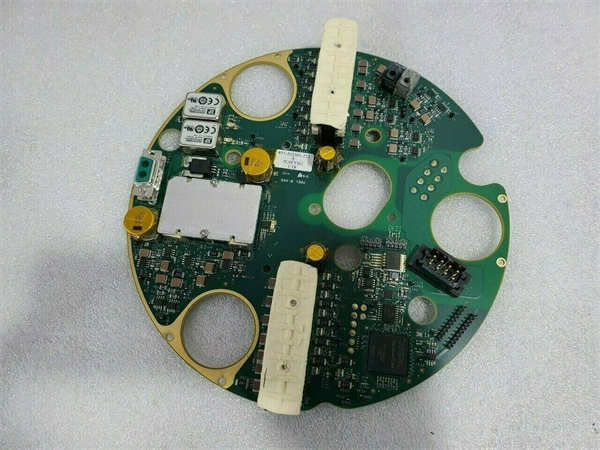

Metso IBC D201138是一款工业级智能控制器,核心功能包括:

多协议兼容:支持Modbus、CANopen、EtherCAT工业协议

电机控制:集成矢量控制算法,支持变频调速与伺服驱动

环境适应性:IP65防护等级,耐受-25°C至60°C环境

模块化扩展:支持I/O扩展卡、通信模块灵活配置

产品详细说明

1.技术架构与功能特性

硬件架构:

处理器:NXP ARM Cortex-A7(主频1GHz)

存储配置:2GB DDR3+8GB eMMC(支持MicroSD卡扩展)

扩展接口:

4×PCIe x1(支持GPU卡、FPGA卡扩展)

8×USB 3.2 Gen2(支持工业摄像头、传感器直连)

软件能力:

电机控制:内置矢量控制算法,支持永磁同步电机(PMSM)与步进电机驱动

协议转换:跨协议数据映射(如将EtherCAT信号转换为Modbus指令)

实时控制:1ms级任务调度,支持1024点I/O并发处理

2.工业环境适配性

极端温度管理:

被动散热设计:采用石墨烯复合材料散热片,60°C环境下温升≤5°C

低温启动:内置PTC加热膜,-25°C环境下启动时间≤30秒

抗振动设计:

结构加固:镁铝合金机身+橡胶减震垫,通过IEC 60068-2-64振动测试

连接器防护:M12工业连接器,抗拉力≥50N

技术规格:Metso IBC D201138

参数项规格描述

处理器NXP ARM Cortex-A7(主频1GHz)

存储配置2GB DDR3+8GB eMMC(支持MicroSD卡扩展)

通信接口4×Gigabit Ethernet(支持PoE++)、2×CAN总线、1×RS485

防护等级IP65(防尘防水)

工作温度-25℃至60℃

电源输入24V DC(冗余双路供电,支持宽电压18-36V)

I/O扩展支持8个PCIe扩展槽(最大扩展至128通道DI/DO)

核心价值与性能亮点

1.智能电机控制

技术突破:某钢铁厂部署IBC D201138后,电机能耗降低15%(基于实时负载调整算法)

2.模块化设计优势

场景适配:在水处理厂中,通过扩展水质分析模块实现pH值、浊度等参数本地化控制,响应延迟≤50ms

应对挑战,创造价值

1.复杂网络环境

技术突破:某海上风电场使用IBC D201138后,网络中断期间数据缓存能力提升至24小时(支持断点续传)

2.多协议系统整合

场景案例:汽车制造厂通过IBC D201138实现DCS系统与MES系统数据互通,集成周期缩短60%

Product brief description

Metso IBC D201138 is an industrial-grade intelligent controller with core functions including:

Multi-protocol compatibility:Supports Modbus,CANopen,and EtherCAT industrial protocols

Motor control:integrated vector control algorithm,supports frequency conversion speed regulation and servo drive

Environmental adaptability:IP65 protection rating,tolerant to-25°C to 60°C environment

Modular expansion:supports flexible configuration of I/O expansion cards and communication modules

Product details

1.Technical architecture and functional characteristics

Hardware architecture:

Processor:NXP ARM Cortex-A7(main frequency 1GHz)

Storage configuration:2GB DDR3+8GB eMMC(supports MicroSD card expansion)

Extended interface:

4×PCIe x1(supports GPU card and FPGA card expansion)

8×USB 3.2 Gen2(supports direct connection of industrial cameras and sensors)

Software capabilities:

Motor control:built-in vector control algorithm,supports permanent magnet synchronous motor(PMSM)and stepper motor drive

Protocol conversion:cross-protocol data mapping(such as converting EtherCAT signals to Modbus instructions)

Real-time control:1ms level task scheduling,supporting 1024-point I/O concurrent processing

2.Industrial environment adaptability

Extreme temperature management:

Passive heat dissipation design:Use graphene composite heat sink,temperature rise≤5°C under 60°C environment

Low temperature start:built-in PTC heating film,start time≤30 seconds under-25°C environment

Vibration-resistant design:

Structural reinforcement:magnesium-aluminum alloy body+rubber shock absorbing pad,passed IEC 60068-2-64 vibration test

Connector protection:M12 industrial connector,tensile resistance≥50N

Technical Specifications:Metso IBC D201138

Parameters Specification Description

Processor NXP ARM Cortex-A7(main frequency 1GHz)

Storage configuration 2GB DDR3+8GB eMMC(supports MicroSD card expansion)

Communication interface 4×Gigabit Ethernet(supports PoE++),2×CAN bus,1×RS485

Protection level IP65(dust-proof and waterproof)

Operating temperature-25℃to 60℃

Power input 24V DC(redundant dual power supply,support wide voltage 18-36V)

I/O expansion supports 8 PCIe expansion slots(maximum expansion to 128 channels DI/DO)

Core Valuesand Performance Highlights

1.Smart motor control

Technical breakthrough:After a steel plant deployed IBC D201138,the motor energy consumption was reduced by 15%(based on real-time load adjustment algorithm)

2.Advantages of modular design

Scenario adaptation:In the water treatment plant,localized control of pH value,turbidity and other parameters through the extended water quality analysis module,with a response delay of≤50ms

Respond to challenges and create value

1.Complex network environment

Technical breakthrough:After an offshore wind farm uses IBC D201138,the data cache capacity has been improved to 24 hours during network interruption(supports breakpoint continuous transmission)

2.Multi-protocol system integration

Scenario case:Automobile manufacturing plants realize data interoperability between DCS system and MES system through IBC D201138,and the integration cycle is shortened by 60%.