描述

产品简要说明

ALSTOM MV3000是一款中高压交流数字变频驱动器,专为重工业场景设计,核心功能包括:

高效能控制:基于PWM技术实现精准的转速与扭矩调节

智能通信:支持CAN-BUS、RS485等多协议通信,兼容工业自动化系统

宽范围适用性:覆盖0.25kW至100MW功率需求,适配冷轧、电力、船舶等复杂场景

产品详细说明

1.硬件架构与核心控制技术

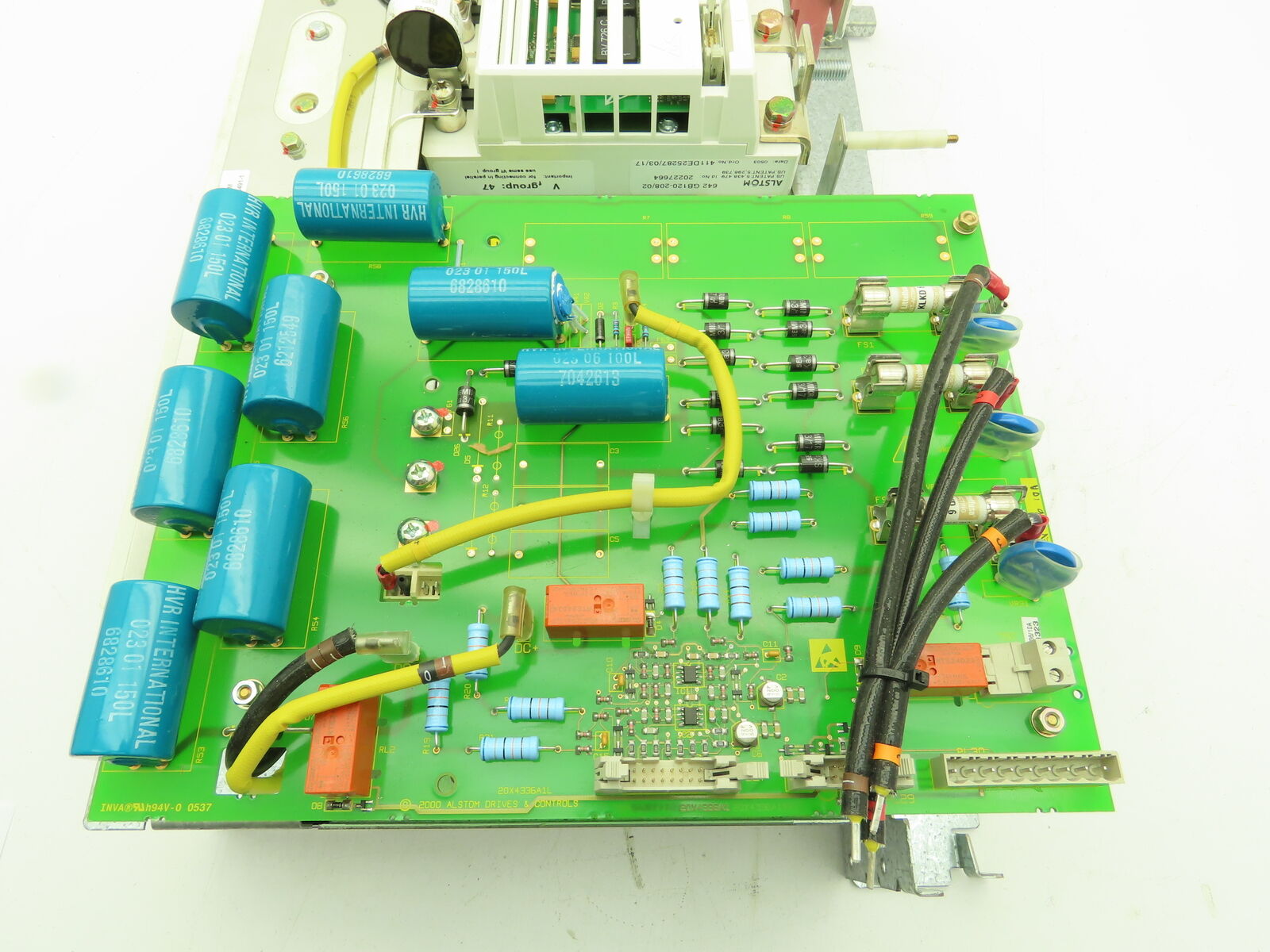

电力电子设计:

采用IGBT全控开关器件,逆变效率达95%以上

无控整流桥输入设计,适应宽电压波动环境

控制算法:

矢量控制:通过速度传感器反馈实现异步电机高精度调速(误差≤0.1%)

自适应算法:动态调整参数以应对负载突变(如冷轧生产线张力控制)

保护机制:

实时监测过压、过流、过温等20+类故障,支持中断保护与故障代码显示

2.通信与集成能力

协议支持:

工业标准协议:Modbus RTU/TCP、CAN-BUS、Profibus

上位机接口:支持RS485/RS232串口及以太网通信

调试工具:

Drive Coach 5.4软件:支持参数配置、故障诊断与远程升级,兼容Windows 7/10系统

3.行业定制化设计

冷轧生产线应用:

集成HPC PID调节器,实现8组”S”辊张力平衡控制

在镀锌线中完成77套传动装置调试,首次热负荷生产即达质量标准

船舶与能源领域:

适配中压大功率需求(如MV4000/MV6000系列扩展),支持海上平台长期稳定运行

技术规格:ALSTOM MV3000

参数项规格描述

输入电压范围380V-1140V AC(中压版)/220V-480V AC(低压版)

输出功率0.25kW至100MW(模块化扩展)

防护等级IP54(标准版)/IP65(特殊定制)

通信接口2×RS485+1×CAN-BUS+1×以太网(1000Mbps)

工作温度-20℃至50℃(扩展至-40℃需定制)

核心价值与性能亮点

1.高精度工业控制

案例应用:在冷轧镀锌线中,通过矢量控制实现8组”S”辊张力恒定,产品合格率提升至99.5%

2.智能诊断与维护

技术突破:Drive Coach 5.4软件可自动生成故障波形分析报告,缩短80%调试时间

应对挑战,创造价值

1.复杂负载波动

技术突破:在钢铁厂高动态负载场景中,通过自适应算法将转速控制响应时间缩短至5ms

2.多协议兼容需求

场景案例:港口自动化码头中,同时支持Modbus与CAN-BUS协议,实现与PLC、SCADA系统无缝对接

Product brief description

ALSTOM MV3000 is a medium and high voltage AC digital frequency converter designed for heavy industry scenarios,with core functions including:

High-performance control:Accurate speed and torque adjustment based on PWM technology

Intelligent communication:Supports multi-protocol communication such as CAN-BUS,RS485,etc.,and is compatible with industrial automation systems

Wide range applicability:Covering power requirements of 0.25kW to 100MW,adapting to complex scenarios such as cold rolling,power,and ships.

Product details

1.Hardware architecture and core control technology

Power Electronics Design:

Adopt IGBT full control switching device,inverter efficiency reaches more than 95%

Uncontrolled rectifier bridge input design,adapt to wide voltage fluctuation environment

Control algorithm:

Vector control:high-precision speed regulation of asynchronous motor through speed sensor feedback(Error≤0.1%)

Adaptive algorithm:dynamically adjust parameters to deal with load sudden changes(such as cold rolling production line tension control)

Protection mechanism:

Real-time monitoring of 20+types of faults such as overvoltage,overcurrent,and overtemperature,supporting interrupt protection and fault code display

2.Communication and integration capabilities

Protocol support:

Industry standard protocol:Modbus RTU/TCP,CAN-BUS,Profibus

Upper computer interface:Support RS485/RS232 serial port and Ethernet communication

Debugging tools:

Drive Coach 5.4 software:supports parameter configuration,troubleshooting and remote upgrade,compatible with Windows 7/10 system

3.Customized design in the industry

Cold rolling production line application:

Integrated HPC PID regulator to achieve 8 sets of”S”roller tension balance control

77 sets of transmission devices were debugged in the galvanized line,and the quality standards were met for the first heat load production

Shipping and Energy:

Adapt to medium voltage high power requirements(such as MV4000/MV6000 series expansion),and supports long-term and stable operation of offshore platforms

Technical Specifications:ALSTOM MV3000

Parameters Specification Description

Input voltage range 380V-1140V AC(medium voltage version)/220V-480V AC(low voltage version)

Output power 0.25kW to 100MW(modular expansion)

Protection level IP54(standard version)/IP65(specially customized)

Communication interface 2×RS485+1×CAN-BUS+1×Ethernet(1000Mbps)

Operating temperature-20℃to 50℃(extended to-40℃requires customization)

Core Valuesand Performance Highlights

1.High-precision industrial control

Case application:In cold-rolled galvanized lines,the tension of 8 sets of”S”rolls is achieved through vector control,and the product pass rate is increased to 99.5%.

2.Intelligent diagnosis and maintenance

Technical breakthrough:Drive Coach 5.4 software can automatically generate fault waveform analysis reports,shortening debugging time by 80%

Respond to challenges and create value

1.Complex load fluctuations

Technical breakthrough:In the high dynamic load scenario of steel plants,the speed control response time is shortened to 5ms through adaptive algorithms

2.Multi-protocol compatibility requirements

Scenario case:In the port automation terminal,it supports Modbus and CAN-BUS protocols to achieve seamless connection with PLC and SCADA systems.