描述

产品简要说明

MAGNETEK GEMCO 1980-103-R-DP-TD2是一款面向泵、风机及传送带系统的工业级变频驱动器,核心特性包括:

智能电机控制:支持矢量控制与V/F控制模式,转矩响应时间≤15ms

多协议兼容:集成Modbus RTU、Profinet DP通信,支持工业4.0集成

宽电压输入:三相200-480V AC,适应复杂电网环境

产品详细说明

1.技术架构与核心功能

智能控制算法:

矢量控制:通过磁场定向控制(FOC)实现高动态响应,转速精度±0.3%

自适应负载补偿:动态调整输出电流,降低机械振动与噪声

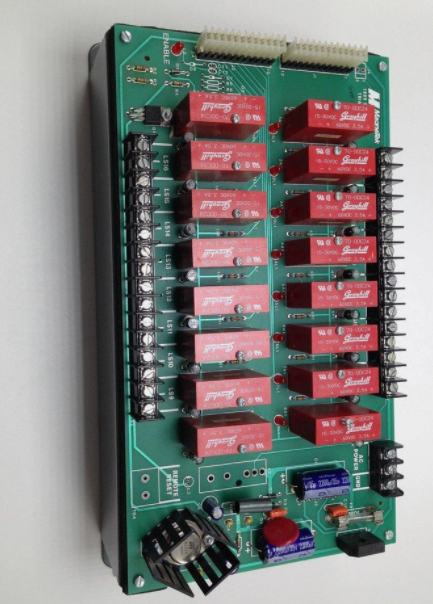

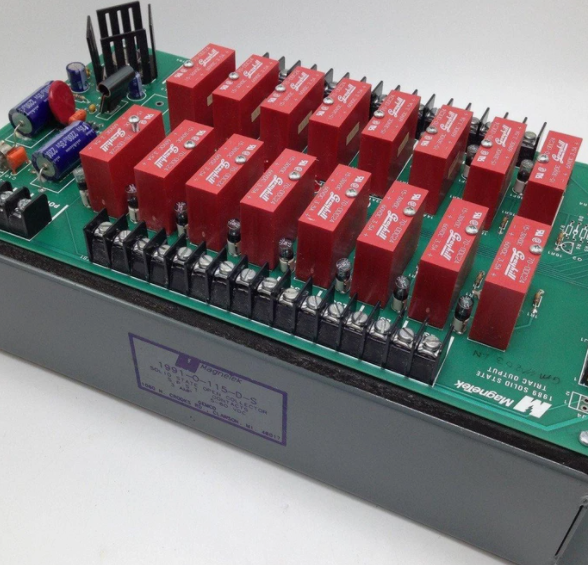

硬件设计:

模块化结构:支持电源、控制板与I/O接口独立更换,维护成本降低40%

抗干扰设计:通过EMC等级Class B认证,适应强电磁环境

2.工业场景适配

泵类应用:

内置防气蚀算法,延长叶轮寿命30%

支持压力闭环控制,流量稳定性±2%

传送带系统:

动态负载补偿功能,减少皮带打滑风险

软启软停时间可调(0.5-60s),降低机械冲击

技术规格:MAGNETEK GEMCO 1980-103-R-DP-TD2

参数项规格描述

输出功率15kW(额定值)

通信接口1×Modbus RTU(RS-485)、1×Profinet DP

控制输入4个数字输入(DC 24V)、2个模拟输入(0-10V/4-20mA)

输出接口2个继电器输出、1个故障报警输出

防护等级IP55(标准)

核心价值与性能亮点

1.高效节能

案例:在某水处理厂中,通过变频调速技术,年节电率达28%。

2.智能运维

功能:

故障诊断系统:支持150+种故障代码定位,提供维修建议

远程监控:通过Profinet DP实现参数读写与运行状态监控

3.行业适配性

优势:

化工领域:耐腐蚀涂层设计,适应酸碱环境

食品加工:IP65防护等级,符合HACCP卫生标准

Product brief description

MAGNETEK GEMCO 1980-103-R-DP-TD2 is an industrial-grade variable frequency driver for pumps,fans and conveyor belt systems.The core features include:

Smart motor control:supports vector control and V/F control mode,torque response time≤15ms

Multi-protocol compatibility:Integrate Modbus RTU,Profinet DP communication,supports Industry 4.0 integration

Wide voltage input:three-phase 200-480V AC,adapted to complex grid environments

Product details

1.Technical architecture and core functions

Intelligent control algorithm:

Vector control:High dynamic response through magnetic field orientation control(FOC),speed accuracy±0.3%

Adaptive load compensation:dynamically adjust the output current to reduce mechanical vibration and noise

Hardware design:

Modular structure:supports independent replacement of power,control board and I/O interface,reducing maintenance costs by 40%.

Anti-interference design:Passed EMC-level Class B certification,adapted to strong electromagnetic environment

2.Adaptation of industrial scenarios

Pump applications:

Built-in anti-cavitation algorithm to extend impeller life by 30%

Supports pressure closed-loop control,flow stability±2%

Conveyor Belt System:

Dynamic load compensation function to reduce the risk of belt slip

Soft start and soft stop time can be adjusted(0.5-60s),reducing mechanical impact

Technical Specifications:MAGNETEK GEMCO 1980-103-R-DP-TD2

Parameters Specification Description

Output power 15kW(rated value)

Communication interface 1×Modbus RTU(RS-485),1×Profinet DP

Control inputs 4 digital inputs(DC 24V),2 analog inputs(0-10V/4-20mA)

Output interface 2 relay outputs,1 fault alarm output

Protection level IP55(standard)

Core Valuesand Performance Highlights

1.High efficiency and energy saving

Case:In a water treatment plant,the annual power saving rate reaches 28%through frequency conversion speed regulation technology.

2.Intelligent operation and maintenance

Function:

Fault diagnosis system:supports 150+types of fault code positioning,providing repair suggestions

Remote monitoring:Use Profinet DP to realize parameter read and write and run status monitoring

3.Industry adaptability

Advantages:

Chemical industry:corrosion-resistant coating design,adapting to acid and alkali environment

Food processing:IP65 protection level,complies with HACCP hygiene standards