描述

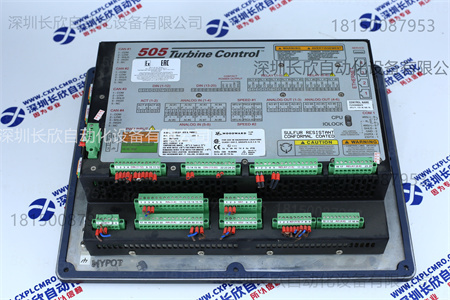

伍德沃德8200-1302是一款高性能的伺服位置控制器,同时也是伍德沃德505D系列涡轮控制产品,主要用于控制蒸汽轮机、发电机和其他旋转设备的转速。以下是其详细产品详情:

基本信息

型号:8200-1302

系列:伍德沃德505D系列

产地:美国

尺寸:170mm×105mm×32mm

输入电压范围:通常为18-36VDC

电源电压:24VDC

功能特点

精确控制:采用高性能微处理器和先进的控制算法,提供快速的控制响应和精确的控制性能,速度精度可达±0.05%,确保设备在所需的速度范围内稳定运行。

多种输入输出:具有两个冗余速度输入,可接受磁性拾取单元、涡流探头或电涡流探头;8个模拟输入,可配置为多种功能;20个触点输入,其中前四个默认为关断提高速度设定点、复位和降低速度设定点,其他的可以根据需要进行配置。此外,还有两个4-20mA控制输出和八个Form-C继电器触点输出。

丰富的报警功能:具备10个外部报警输入和10个外部DI跳闸输入,提供丰富的故障检测和报警功能。同时,跳闸和报警事件有跳闸指示以及相关的RTC时间戳,有助于用户快速定位和分析故障。

多种运行模式:提供三种正常运行模式,包括配置模式、操作模式和校准模式。配置模式用于设备的初始配置和参数设置;操作模式允许从启动到关闭的正常操作;校准模式允许在设备关闭或正常运行期间进行校准和调整。

通信功能:支持Modbus RTU、RS485、CANbus等协议,可与其他设备和系统进行通信和集成。

应用场景

发电领域:用于控制发电机组的转速,确保电力系统的稳定运行。

石油和天然气领域:控制油气设备的转速,如泵、压缩机等。

船舶领域:控制船舶动力系统的转速,适应不同航行条件。

The Woodward 8200-1302 is a high-performance servo position controller and part of the Woodward 505D series turbine control product,primarily used for speed control of steam turbines,generators,and other rotating equipment.The following are product details:

Basic Information

Model:8200-1302

Series:Woodward 505D Series

Origin:USA

Dimensions:170mm×105mm×32mm

Input Voltage Range:Typically 18-36VDC

Power Supply Voltage:24VDC

Features

Precise Control:Utilizing a high-performance microprocessor and advanced control algorithms,it provides fast control response and precise control performance,with speed accuracy reaching±0.05%,ensuring stable operation within the required speed range.

Multiple Inputs and Outputs:Features two redundant speed inputs that accept magnetic pickup units,eddy current probes,or eddy current probes;eight analog inputs configurable for various functions;and 20 contact inputs.The first four default to shutting down the speed setpoint(increase,reset,and decrease),while the others can be configured as needed.In addition,there are two 4-20mA control outputs and eight Form-C relay contact outputs.

Extensive Alarm Functionality:10 external alarm inputs and 10 external DI trip inputs provide extensive fault detection and alarm capabilities.Trip and alarm events are accompanied by trip indications and associated RTC timestamps,helping users quickly locate and analyze faults.

Multiple Operating Modes:Three normal operating modes are provided:Configuration Mode,Operation Mode,and Calibration Mode.Configuration Mode is used for initial device configuration and parameter setting;Operation Mode allows normal operation from startup to shutdown;and Calibration Mode allows calibration and adjustments during shutdown or normal operation.

Communication Functionality:Supports Modbus RTU,RS485,CANbus,and other protocols,enabling communication and integration with other devices and systems.

Application Scenarios

Power Generation:Used to control the speed of generator sets to ensure stable power system operation.

Oil and Gas:Controls the speed of oil and gas equipment,such as pumps and compressors.

Marine:Controls the speed of ship propulsion systems to adapt to varying sailing conditions.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101