描述

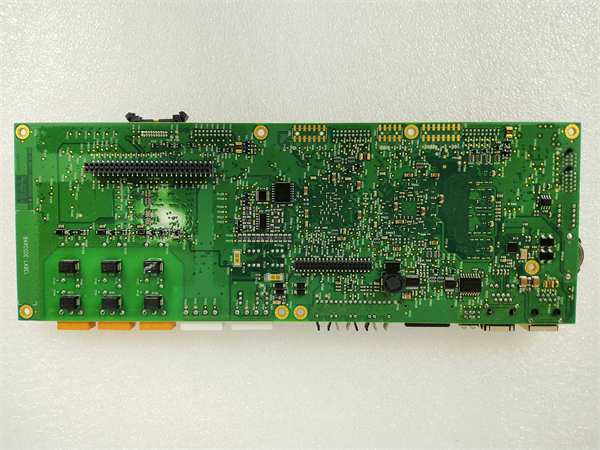

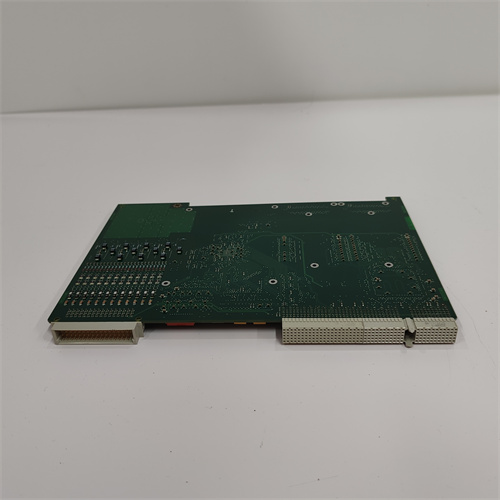

1MRK002133-ABr02是ABB公司的一款电线端接模块,具备以下产品详情:

一、核心功能

程序状态监控与版本管理:

状态监控:能够显示所有机器编程的当前正确状态,方便用户实时了解设备运行情况。

版本管理:记录所有更改的版本历史记录,并通过表格和图形报告详细展示程序差异,便于用户追踪和管理程序变更。

自动备份与恢复:

自动备份:支持自动程序备份功能,只需单击几下即可恢复以前的版本,节省时间并避免产品错误。

灵活备份:自动备份适用于单个设备或整个工厂,即使面对由数百甚至数千个设备和传感器以及硬件和软件组件组成的复杂系统,也能轻松实现数据备份。

可靠的电线端接:

端接方案:为螺钉和推入式端子提供可靠的电线端接解决方案,确保电气连接的稳定性和安全性。

配套零件:提供适当额定的零件和相关工具,方便安装人员和技术人员进行连接操作。

二、技术特性

混合集成平台:

集成组件:汇集了一套全面的集成组件,这些组件经过设计和优化后可协同工作,提升系统整体性能。

部署环境:部署在Red Hat OpenShift上,支持灵活的部署和扩展。

特征与编码识别:

模式匹配:软件采用模式匹配的方式进行特征和编码识别,提高识别准确性和效率。

识别功能:包括特征识别和编码识别,能够识别工件的特征信息(如类型、位置坐标和R偏角)以及工件上的喷码信息,实现自动分拣下料。

安全保护与报警:

传感器检测:夹具上的传感器可以实现工件有无的检测,通过PLC实现对工件掉落、吸附失败等情况的判断及报警。

安全保护:对机械手抓取过程中下降高度进行安全保护,通过调节传感器判定距离,实现机械手下降高度超出安全高度时的防护及停机。

1MRK002133-ABr02 is a wire termination module from ABB,with the following product details:

I.Core functions

Program status monitoring and version management:

Status monitoring:It can display the current correct status of all machine programming,so that users can understand the operation of the equipment in real time.

Version management:It records the version history of all changes and displays the program differences in detail through tables and graphical reports,so that users can track and manage program changes.

Automatic backup and recovery:

Automatic backup:It supports automatic program backup function,and can restore previous versions with just a few clicks,saving time and avoiding product errors.

Flexible backup:Automatic backup is suitable for single equipment or entire factories,and data backup can be easily achieved even in the face of complex systems consisting of hundreds or even thousands of devices and sensors as well as hardware and software components.

Reliable wire termination:

Termination scheme:It provides reliable wire termination solutions for screws and push-in terminals to ensure the stability and safety of electrical connections.

Matching parts:It provides appropriately rated parts and related tools to facilitate installation personnel and technicians to perform connection operations.

2.Technical Features

Hybrid integration platform:

Integrated components:It brings together a comprehensive set of integrated components that are designed and optimized to work together to improve the overall performance of the system.

Deployment environment:It is deployed on Red Hat OpenShift,which supports flexible deployment and expansion.

Feature and code recognition:

Pattern matching:The software uses pattern matching to perform feature and code recognition to improve recognition accuracy and efficiency.

Recognition function:It includes feature recognition and code recognition,which can recognize the feature information of the workpiece(such as type,position coordinates and R deflection angle)and the inkjet information on the workpiece to realize automatic sorting and unloading.

Safety protection and alarm:

Sensor detection:The sensor on the fixture can detect the presence of the workpiece,and the PLC can be used to judge and alarm the situation of workpiece falling,adsorption failure,etc.

Safety protection:Safety protection is provided for the descending height of the manipulator during the grasping process.By adjusting the sensor to determine the distance,the manipulator can be protected and shut down when the descending height exceeds the safe height.