描述

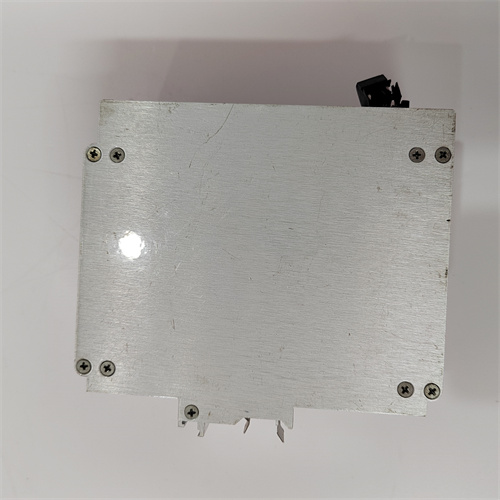

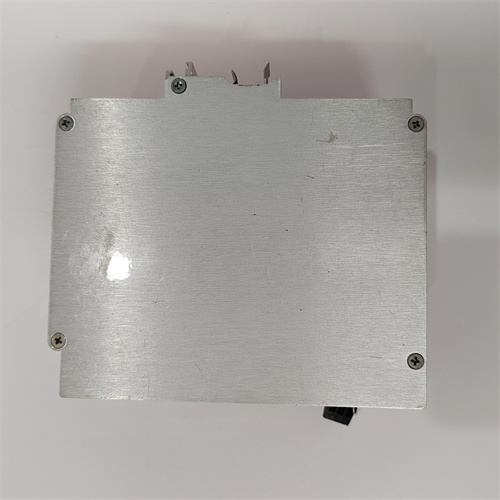

202-DFNT-MCM4是Prosoft Technology生产的一款工业通信模块,专为工业自动化和控制系统设计,以下是其产品详情:

一、核心功能

多协议支持与转换:

支持多种工业通信协议的转换,包括但不限于Modbus、EtherNet/IP、DF1、DeviceNet、Profibus等,能够在不同的设备和控制系统之间进行数据传输。

实现不同网络之间的数据桥接,使得不兼容的网络能够相互通信,提高系统的集成性和互操作性。

高性能数据处理:

提供快速的数据传输速率,确保在复杂的工业环境中能够高效地处理大量数据。

配备以太网接口,用于连接到EtherNet/IP网络,实现与其他以太网设备的通信。

实时监控与诊断:

支持实时监控网络状态和通信流量,帮助用户及时发现和解决问题。

内置诊断工具,可以快速识别和解决通信问题,提升系统的维护效率。

二、技术特性

接口与配置:

提供多种通信接口选项,如RS-232、RS-485、Ethernet等,支持广泛的设备连接。

支持灵活的接口配置,以满足不同的通信需求和网络环境。用户可以根据需要调整适配器的工作参数和通信设置。

可靠性与耐用性:

设计坚固,采用工业级材料和设计,能够在恶劣的工业环境中稳定运行,适合24/7不间断的工业应用。

具备良好的抗干扰能力,确保通信的稳定性和可靠性。

模块化与可扩展性:

模块化设计,支持在不同的应用场景中灵活配置和扩展。

紧凑的模块尺寸适合各种机柜安装,便于系统集成和维护。

三、应用领域

工厂自动化:

用于在不同品牌的PLC(可编程逻辑控制器)之间传输数据,实现跨平台的设备通信。

支持罗克韦尔自动化的CLX、SLC、PLC、CPLX等多种PLC设备,为Modbus设备提供广泛的接口支持。

过程控制:

适用于石油、化工、水处理等行业中的过程控制系统,用于连接和集成不同的控制设备。

支持多种Modbus功能码,如读取输出状态、读取输入状态、读取多个数据寄存器等,满足不同的通信需求。

电力和能源:

在电力分配和管理系统中,用于不同设备间的数据交换和监控。

支持冗余保护功能,提高系统的可靠性和容错能力。

物联网(IoT):

可作为工业物联网系统的一部分,用于数据采集和远程监控。

支持远程监控和管理功能,方便对设备和生产过程进行实时监测和控制。

202-DFNT-MCM4 is an industrial communication module produced by Prosoft Technology,designed for industrial automation and control systems.The following are its product details:

1.Core functions

Multi-protocol support and conversion:

Supports the conversion of multiple industrial communication protocols,including but not limited to Modbus,EtherNet/IP,DF1,DeviceNet,Profibus,etc.,and can transmit data between different devices and control systems.

Realize data bridging between different networks,so that incompatible networks can communicate with each other,improving the integration and interoperability of the system.

High-performance data processing:

Provides fast data transmission rate to ensure that large amounts of data can be processed efficiently in complex industrial environments.

Equipped with Ethernet interface for connecting to EtherNet/IP network to achieve communication with other Ethernet devices.

Real-time monitoring and diagnosis:

Supports real-time monitoring of network status and communication traffic to help users discover and solve problems in a timely manner.

Built-in diagnostic tools can quickly identify and solve communication problems and improve system maintenance efficiency.

2.Technical Features

Interface and Configuration:

Provide a variety of communication interface options,such as RS-232,RS-485,Ethernet,etc.,to support a wide range of device connections.

Support flexible interface configuration to meet different communication needs and network environments.Users can adjust the working parameters and communication settings of the adapter as needed.

Reliability and Durability:

The design is sturdy,using industrial-grade materials and design,and can operate stably in harsh industrial environments,suitable for 24/7 uninterrupted industrial applications.

Possess good anti-interference ability to ensure the stability and reliability of communication.

Modularity and Scalability:

Modular design supports flexible configuration and expansion in different application scenarios.

The compact module size is suitable for various cabinet installations,which facilitates system integration and maintenance.

3.Application Fields

Factory Automation:

Used to transmit data between PLCs(Programmable Logic Controllers)of different brands to achieve cross-platform device communication.

Supports a variety of PLC devices such as CLX,SLC,PLC,CPLX of Rockwell Automation,and provides a wide range of interface support for Modbus devices.

Process control:

Applicable to process control systems in industries such as petroleum,chemical,and water treatment,used to connect and integrate different control devices.

Supports a variety of Modbus function codes,such as reading output status,reading input status,reading multiple data registers,etc.,to meet different communication needs.

Power and energy:

In power distribution and management systems,it is used for data exchange and monitoring between different devices.

Supports redundant protection functions to improve system reliability and fault tolerance.

Internet of Things(IoT):

Can be used as part of the industrial Internet of Things system for data acquisition and remote monitoring.

Supports remote monitoring and management functions to facilitate real-time monitoring and control of equipment and production processes.