描述

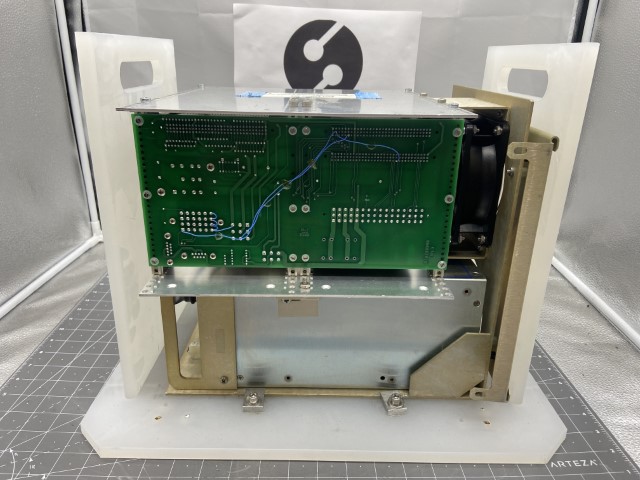

产品简要说明

ASML 879-8234-007是一款专为浸润式光刻机设计的光学系统核心组件,核心功能包括:

高精度滤波调控:支持光学透镜组波前畸变补偿精度≤0.05λ( 633nm),光谱滤波带宽稳定性达±0.2nm。

多光谱兼容性:集成紫外(UV)、深紫外(DUV)及极紫外(EUV)三波段滤波模块,光谱响应范围193nm-13.5nm。

抗污染设计:通过ASML洁净度认证(Class 0),表面颗粒物控制≤10^9 atoms/cm²。

产品详细说明

1.技术架构与创新

模块化光学设计:

复合滤波结构:采用熔融石英基底+多层膜堆叠技术,透光率≥98%( 193nm)。

动态补偿机制:内置压电陶瓷驱动器(分辨率0.1nm),波前畸变补偿响应时间<100μs。

通信协议栈:

EtherCAT从站:支持ASML工艺参数库实时加载(兼容800+光刻工艺包)。

ASML私有协议:实现滤波参数与光刻机曝光剂量的动态同步。

2.核心功能模块

多光谱滤波:

波长选择性:支持EUV(13.5nm)、ArF(193nm)、KrF(248nm)三波段切换,切换时间<50ms。

光谱稳定性:通过激光外差干涉仪监测,带宽漂移≤0.05nm/小时。

环境自适应:

温度补偿:集成热敏电阻阵列,环境温度波动补偿精度达±0.01℃。

真空兼容性:支持10^-6 Torr真空环境运行,机械变形量≤0.1nm。

3.行业应用适配性

浸润式光刻机:

光学路径优化:实现浸润液(如水)折射率匹配误差≤0.001,曝光均匀性提升15%。

高能光束管理:支持EUV光刻机250W激光功率传输,能量损耗≤0.5%。

精密光学系统:

多光束干涉:兼容激光干涉仪校准,相位噪声控制≤10^-3 rad。

抗激光损伤:通过ASML激光损伤阈值测试(LIDT≥5J/cm² 13.5nm)。

技术规格:ASML 879-8234-007

参数项规格描述

光谱范围13.5nm(EUV)/193nm(ArF)/248nm(KrF)

透光率≥98%( 193nm),≥95%( 13.5nm)

波前畸变≤0.05λ(RMS)

工作温度20℃±0.1℃(恒温控制模式)

功耗≤30W(连续运行)

Product brief description

ASML 879-8234-007 is an optical system core component designed for immersive lithography machines.The core functions include:

High-precision filtering regulation:supports wavefront distortion compensation accuracy of optical lens group≤0.05λ( 633nm),and the spectral filter bandwidth stability reaches±0.2nm.

Multi-spectral compatibility:Integrated ultraviolet(UV),deep ultraviolet(DUV)and extreme ultraviolet(EUV)three-band filter modules,with a spectral response range of 193nm-13.5nm.

Anti-pollution design:Passed ASML cleanliness certification(Class 0),surface particulate matter control≤10^9 atoms/cm².

Product details

1.Technical Architecture and Innovation

Modular optical design:

Composite filter structure:adopts fused quartz substrate+multi-layer film stacking technology,with a light transmittance of≥98%( 193nm).

Dynamic compensation mechanism:built-in piezoelectric ceramic driver(resolution 0.1nm),wavefront distortion compensation response time<100μs.

Communication protocol stack:

EtherCAT slave:supports real-time loading of ASML process parameter library(compatible with 800+lithography process packages).

ASML private protocol:realizes dynamic synchronization of filter parameters and exposure dose of lithography machine.

2.Core functional modules

Multispectral filtering:

Wavelength selectivity:Supports three-band switching between EUV(13.5nm),ArF(193nm),and KrF(248nm),with a switching time<50ms.

Spectral stability:Monitored by laser heterodyne interferometer,bandwidth drift≤0.05nm/hour.

Environmental adaptation:

Temperature compensation:Integrated thermistor array,the ambient temperature fluctuation compensation accuracy reaches±0.01℃.

Vacuum compatibility:Supports operation in 10^-6 Torr vacuum environment,mechanical deformation amount≤0.1nm.

3.Industry application adaptability

Immersive lithography machine:

Optical path optimization:Achieves the refractive index matching error of the wetted liquid(such as water)with an≤0.001,and an exposure uniformity is improved by 15%.

High-energy beam management:supports 250W laser power transmission of EUV lithography machine,energy loss is≤0.5%.

Precision optical system:

Multi-beam interference:compatible with laser interferometer calibration,phase noise control≤10^-3 rad.

Anti-laser damage:Passed the ASML laser damage threshold test(LIDT≥5J/cm² 13.5nm).

Technical Specifications:ASML 879-8234-007

Parameters Specification Description

Spectral range 13.5nm(EUV)/193nm(ArF)/248nm(KrF)

Light transmittance≥98%( 193nm),≥95%( 13.5nm)

Wavefront distortion≤0.05λ(RMS)

Operating temperature:20℃±0.1℃(constant temperature control mode)

Power consumption≤30W(continuous operation)