描述

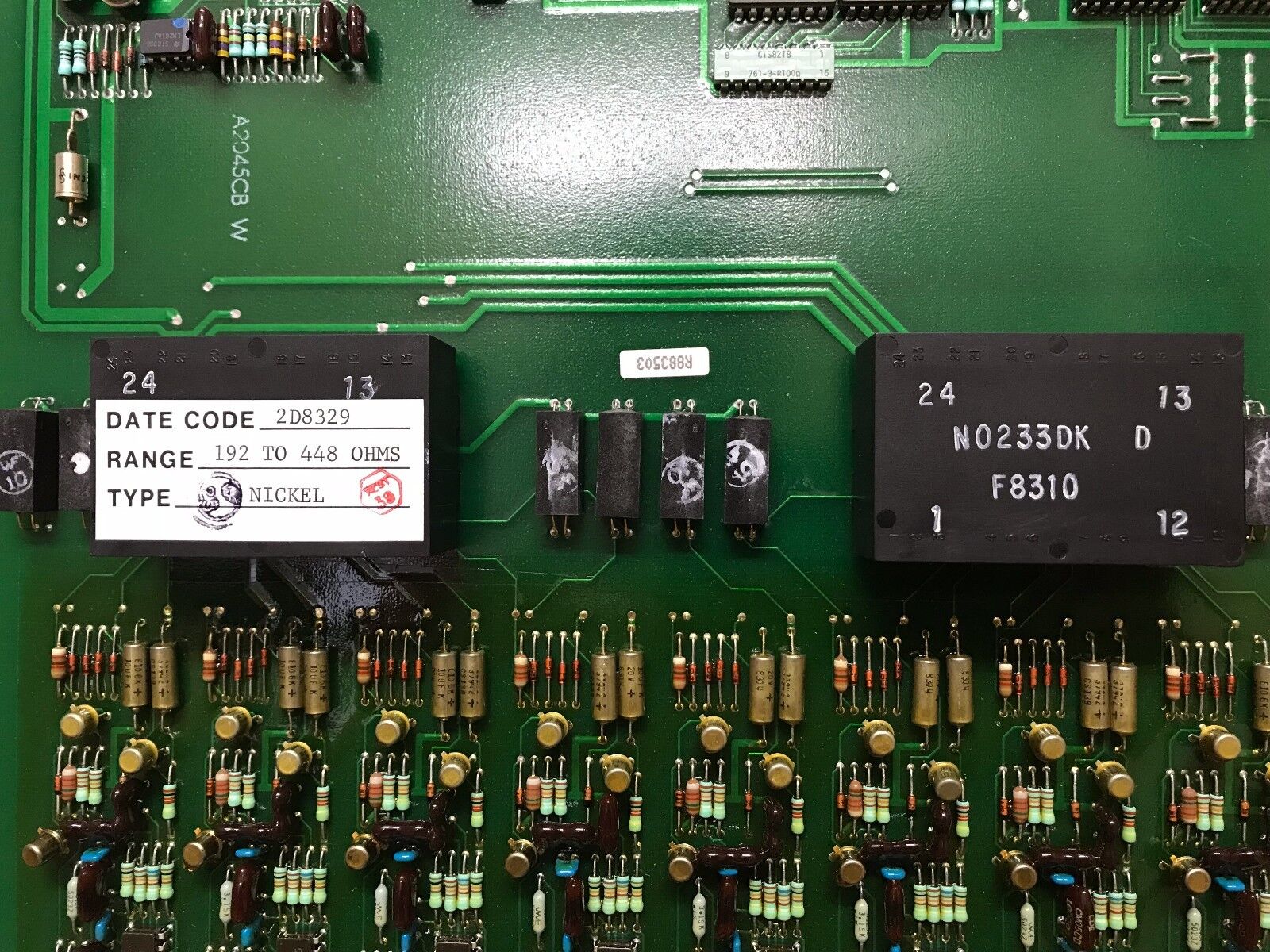

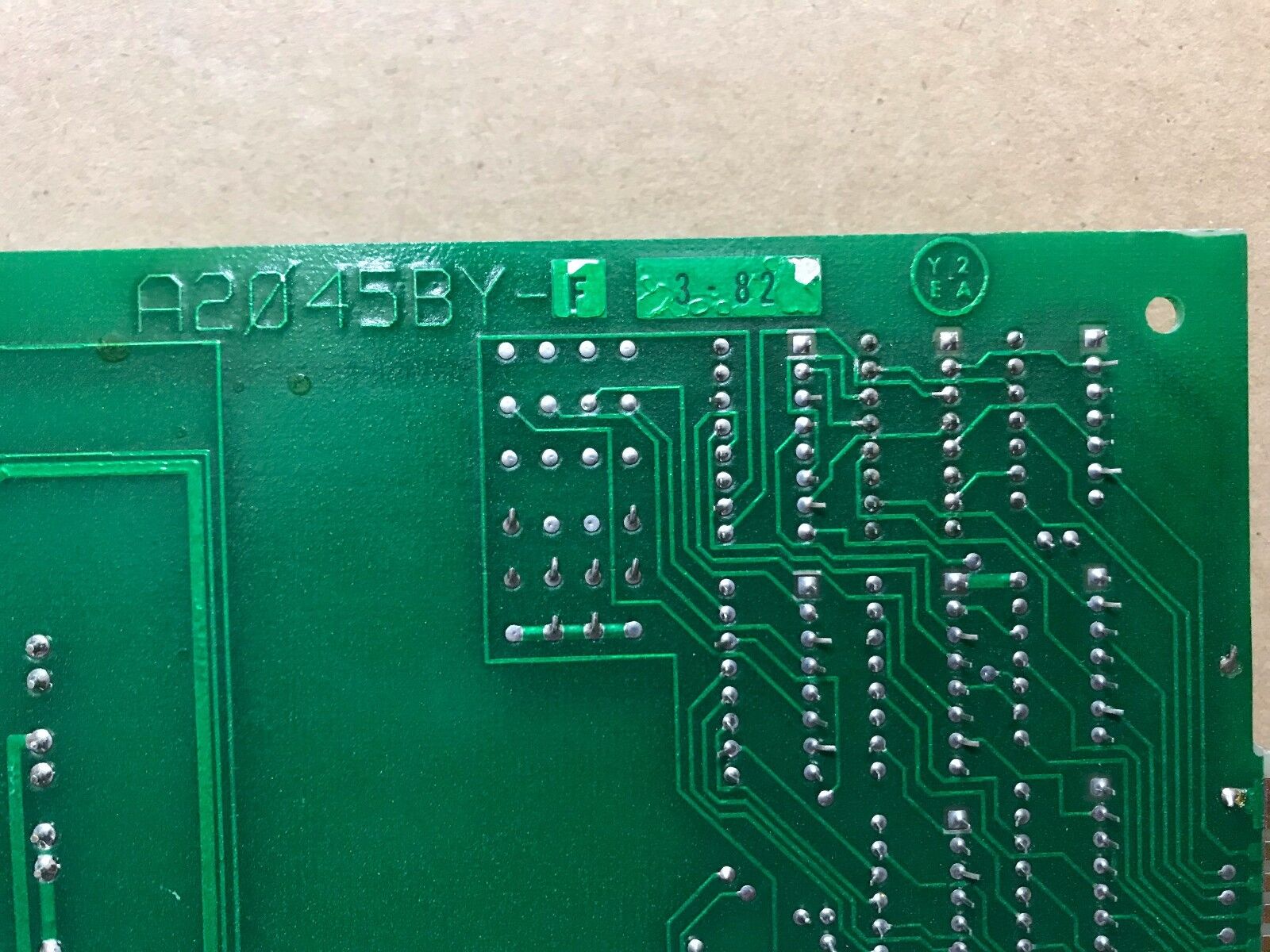

A2045CB FOXBORO

产品说明及技术文档

SEO优化标题生成

(共10个,覆盖不同关键词组合)

A2045CB FOXBORO:工业自动化控制模块,过程控制核心组件!

福克斯波罗A2045CB深度解析:高性能DCS/PLC系统集成方案!

过程控制优化:A2045CB如何提升工厂自动化效率?**

防爆认证与高精度控制:A2045CB在危险环境中的应用实践!**

兼容多协议与灵活配置:福克斯波罗A2045CB的通信与扩展能力!**

工业级可靠性:A2045CB通过哪些严苛环境测试?**

石油化工行业专用:A2045CB在温度、压力监测中的核心作用!**

系统集成与快速部署:从选型到调试的A2045CB全流程指南!**

福克斯波罗DCS系统关键模块:A2045CB与其他组件的协作优势!**

维护成本降低:A2045CB的自诊断与故障预警功能!**

产品简要说明

A2045CB FOXBORO:

核心定位:高性能工业控制模块,适用于DCS(分布式控制系统)或PLC(可编程逻辑控制器)系统。

技术特点:多协议通信、高精度信号处理、防爆设计、环境适应性强、灵活配置。

应用场景:石油化工厂过程控制、电力设备监控、制药生产自动化、环境监测系统等。

核心价值:提升系统可靠性、简化集成流程、降低维护成本、增强数据安全性。

产品详细说明

##产品概述:A2045CB FOXBORO

A2045CB是福克斯波罗(现施耐德电气旗下)推出的工业控制模块,通常作为DCS或PLC系统的关键组成部分,用于信号处理、逻辑控制和通信管理:

设计定位:支持复杂工业环境下的实时控制与数据采集,具备高可靠性和稳定性。

功能特性:可处理模拟/数字信号,支持多协议通信(如HART、Modbus、基金会现场总线等),兼容多种传感器与执行器。

环境适应性:防爆设计(可能具备ATEX、IECEx认证),适应高温、振动、腐蚀性气体等恶劣环境。

配置灵活性:通过编程或配置工具,可自定义参数、逻辑算法和报警阈值。

集成优势:与福克斯波罗其他控制系统(如I/A Series)无缝兼容,简化系统集成与维护。

##技术规格:A2045CB FOXBORO

(表格格式)

参数名称规格值备注

型号A2045CB

品牌FOXBORO(施耐德电气)

类型工业控制模块

输入类型模拟(4-20mA、热电偶、RTD)、数字(开关量)支持类型需参考具体配置

输出信号模拟/数字(继电器、晶体管)可配置

通信协议HART、Modbus、基金会现场总线、以太网根据版本可选

精度等级±0.1%量程(典型)取决于传感器与校准

环境温度-40℃至+85℃(操作),-50℃至+100℃(存储)

防护等级IP65/IP67(可选)防爆版本需确认认证

电源要求24VDC(±10%),或85-265VAC根据实际型号后缀

安装方式DIN导轨安装、面板安装

认证ATEX、IECEx、CE、FM(部分版本)依版本而定

编程环境福克斯波罗专用组态软件或第三方平台如Foxboro Control Studio

响应时间≤10ms(典型)依信号类型

冗余功能可选(热备冗余或通信冗余)定制配置

诊断功能自诊断、故障报警、历史记录

##核心价值与性能亮点

高精度与可靠性:

信号处理精度达0.1%量程,确保过程控制的准确性。

多协议兼容性:

支持HART、Modbus等主流协议,简化跨品牌系统集成。

环境适应性:

防爆认证与宽温设计,适用于石油、化工等危险场所。

灵活配置与编程:

通过组态软件自定义逻辑,快速适配不同工艺需求。

诊断与维护优化:

自诊断功能实时监测状态,提前预警故障,降低停机风险。

数据安全与冗余:

可选冗余配置,保障关键控制环节的连续性。

品牌生态整合:

与福克斯波罗DCS系统无缝集成,提升整体解决方案效率。

A2045CB FOXBORO

Product description and technical documentation

SEO Optimized Title Generation

(Total 10,covering different keyword combinations)

A2045CB FOXBORO:Industrial automation control module,process control core component!

Foxpolo A2045CB in-depth analysis:high-performance DCS/PLC system integration solution!

Process control optimization:How does A2045CB improve factory automation efficiency?**

Explosion-proof certification and high-precision control:the application practice of A2045CB in hazardous environments!**

Compatible with multi-protocol and flexible configuration:the communication and expansion capabilities of Foxpolo A2045CB!**

Industrial-grade reliability:What rigorous environmental tests have the A2045CB passed?**

Special for petrochemical industry:the core role of A2045CB in temperature and pressure monitoring!**

System integration and rapid deployment:A2045CB full process guide from selection to debugging!**

Foxpolo DCS system key module:the collaborative advantages of A2045CB with other components!**

Reduced maintenance cost:A2045CB’s self-diagnosis and fault warning functions!**

Product brief description

A2045CB FOXBORO:

Core positioning:High-performance industrial control module,suitable for DCS(distributed control system)or PLC(programmable logic controller)systems.

Technical features:multi-protocol communication,high-precision signal processing,explosion-proof design,strong environmental adaptability,flexible configuration.

Application scenarios:petrochemical plant process control,power equipment monitoring,pharmaceutical production automation,environmental monitoring systems,etc.

Core values:Improve system reliability,simplify integration processes,reduce maintenance costs,and enhance data security.

Product details

##Product Overview:A2045CB FOXBORO

The A2045CB is an industrial control module launched by Foxpolo(now under Schneider Electric)and is usually a key component of DCS or PLC systems for signal processing,logic control and communication management:

Design positioning:Supports real-time control and data acquisition in complex industrial environments,with high reliability and stability.

Functional features:can handle analog/digital signals,support multi-protocol communication(such as HART,Modbus,Foundation fieldbus,etc.),and is compatible with a variety of sensors and actuators.

Environmental adaptability:Explosion-proof design(may be ATEX,IECEx certification),adapting to harsh environments such as high temperature,vibration,corrosive gases.

Configuration flexibility:Customize parameters,logic algorithms,and alarm thresholds through programming or configuration tools.

Integration Advantages:Seamless compatibility with other Foxpolo control systems(such as I/A Series)to simplify system integration and maintenance.

##Technical Specifications:A2045CB FOXBORO

(Table format)

Parameter Name Specification Value Note

Model A2045CB

Brand FOXBORO(Schneider Electric)

Type Industrial Control Module

Input type Analog(4-20mA,thermocouple,RTD),digital(switch quantity)Support type requires specific configuration

Output signal Analog/digital(relay,transistor)Configurable

Communication protocol HART,Modbus,Foundation fieldbus,Ethernet can be selected according to the version

Accuracy level±0.1%Range(typical)Depend on sensor and calibration

Ambient temperature-40℃to+85℃(operation),-50℃to+100℃(storage)

Protection level IP65/IP67(optional)Explosion-proof version requires confirmation and certification

Power supply requirements:24VDC(±10%),or 85-265VAC suffix according to actual model

Installation method DIN rail installation,panel installation

Certification ATEX,IECEx,CE,FM(partial versions)Depend on version

Programming environment Foxboro special configuration software or third-party platform such as Foxboro Control Studio

Response time≤10ms(typical)By signal type

Redundancy function Optional(hot standby redundancy or communication redundancy)Custom configuration

Diagnostic functions:Self-diagnosis,fault alarm,historical records

##Core Values and Performance Highlights

High precision and reliability:

The signal processing accuracy reaches 0.1%range,ensuring the accuracy of process control.

Multi-protocol compatibility:

Support mainstream protocols such as HART and Modbus to simplify cross-brand system integration.

Environmental adaptability:

Explosion-proof certification and wide temperature design,suitable for dangerous places such as petroleum and chemical industry.

Flexible configuration and programming:

Custom logic through configuration software to quickly adapt to different process needs.

Diagnosis and maintenance optimization:

The self-diagnosis function monitors the status in real time,warnings for failures in advance,and reduces the risk of downtime.

Data security and redundancy:

Optional redundant configurations ensure the continuity of key control links.

Brand Ecosystem Integration:

Seamless integration with Foxpolo DCS system to improve overall solution efficiency.