描述

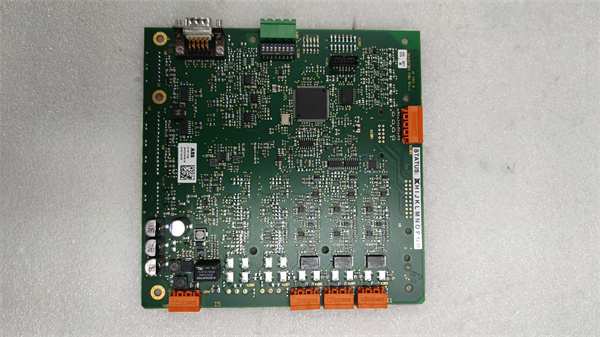

ABB 3ASC25H204是一款多用途工业自动化模块,涵盖电源、控制、通信及信号处理功能,广泛应用于工业控制、机器人系统、智能设备等领域。以下是其核心功能与技术特点的综合概述:

一、核心功能与技术特点

无线通信与物联网集成

-支持Wi-Fi连接,符合行业认证标准,兼容性与稳定性强。

-即插即用设计简化物联网设备开发,适用于智能家居、智能电网等场景。

-低功耗技术优化,延长电池供电设备的续航时间。

电源管理模块

-输入电压范围20.4-28.8V DC,输出24V DC/4A,额定功率96W,效率达90%。

-集成过压、欠压、过流、短路及热保护功能,工作温度-20℃至60℃。

-尺寸紧凑(125×45×110mm),适用于工业控制系统、楼宇自动化等场景。

输入/输出控制模块

-用于ABB机器人及工业自动化系统的信号控制,支持RS-485/RS-422接口,终端电阻120Ω配置。

-多种输入输出选项,兼容数字量与模拟量信号,适用于制造业、化工、能源等领域。

-高可靠性设计,确保机器人运动控制的精准度与稳定性。

数字流量计数模块

-支持脉冲信号或计数器输入,可同时监测多个流量计,实时显示计数结果及速率。

-集成数据接口(如以太网、RS-232/485),兼容PLC系统,适用于生产线计数、物流管理等场景。

-高精度(0.1-0.5%)与防护等级(IP67/68),适应复杂工业环境。

二、应用场景

工业自动化

-机器人系统控制、传感器数据传输、设备状态监测。

-集成到DCS或PLC系统,实现分布式控制与数据采集。

智能电网

-电力设备远程监控、能耗管理、故障诊断。

-低功耗特性符合绿色能源要求。

智能制造

-生产线计数、质量检测、设备维护预测。

-与MES系统集成,优化生产流程。

智能家居

-智能灯控、安防联动、环境监测。

-Wi-Fi即插即用简化设备部署。

SCYC51010 58052515G

SCYC51010 58052515G

ABB 3ASC25H204 is a multi-purpose industrial automation module that covers power,control,communication and signal processing functions.It is widely used in industrial control,robotic systems,smart devices and other fields.The following is a comprehensive overview of its core functions and technical features:

I.Core functions and technical features

Wireless communication and IoT integration

-Support Wi-Fi connection,meet industry certification standards,and have strong compatibility and stability.

-Plug-and-play design simplifies IoT device development and is suitable for scenarios such as smart homes and smart grids.

-Low-power technology optimization extends the battery life of battery-powered devices.

Power management module

-Input voltage range 20.4-28.8V DC,output 24V DC/4A,rated power 96W,efficiency 90%.

-Integrated overvoltage,undervoltage,overcurrent,short circuit and thermal protection functions,operating temperature-20℃to 60℃.

-Compact size(125×45×110mm),suitable for scenarios such as industrial control systems and building automation.

Input/output control module

-Used for signal control of ABB robots and industrial automation systems,supports RS-485/RS-422 interface,terminal resistance 120Ωconfiguration.

-Multiple input and output options,compatible with digital and analog signals,suitable for manufacturing,chemical,energy and other fields.

-High reliability design to ensure the accuracy and stability of robot motion control.

Digital flow counting module

-Supports pulse signal or counter input,can monitor multiple flow meters at the same time,and display counting results and rates in real time.

-Integrated data interface(such as Ethernet,RS-232/485),compatible with PLC system,suitable for production line counting,logistics management and other scenarios.

-High accuracy(0.1-0.5%)and protection level(IP67/68),adaptable to complex industrial environments.

II.Application scenarios

Industrial automation

-Robot system control,sensor data transmission,equipment status monitoring.

-Integrate into DCS or PLC system to realize distributed control and data acquisition.

Smart grid

-Remote monitoring of power equipment,energy consumption management,fault diagnosis.

-Low power consumption meets green energy requirements.

Smart Manufacturing

-Production line counting,quality inspection,equipment maintenance prediction.

-Integration with MES system to optimize production process.

Smart Home

-Smart lighting control,security linkage,environmental monitoring.

-Wi-Fi plug-and-play simplifies device deployment.