描述

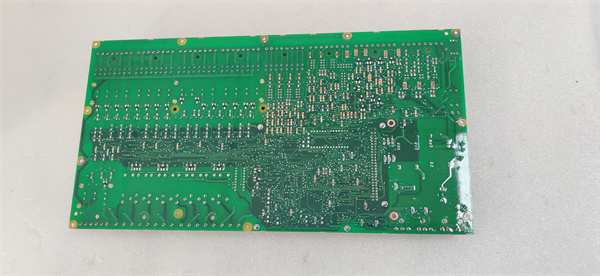

ABB 3ASC25H219B DATX133是一款多功能工业自动化组件,兼具转子反馈与可编程控制功能,广泛应用于工业领域的精密控制场景。以下是其核心功能与技术特点的综合解析:

一、产品定位与核心功能

转子反馈板

-作为转子位置检测与速度反馈模块,专为ABB变频器设计,接收并处理转子信号,实现电机控制系统的高精度闭环反馈。

-高精度传感器技术:快速、准确测量转子位置,支持电力、化工、石油、冶金等行业的电动机控制系统。

可编程控制系统组件

-兼容可编程逻辑控制(PLC),支持逻辑控制、运动控制及温度控制等多场景需求。

-模块化设计:可通过扩展实现小型至大型项目的灵活配置,与ABB其他产品无缝集成。

二、技术特性

高可靠性与稳定性

-采用高质量电子元件,具备抗干扰能力及宽温工作范围(-40°C至+85°C),适用于严苛工业环境。

-支持故障自诊断,快速定位潜在问题。

通信与编程能力

-数字通信协议:支持以太网、Profibus等协议,实现与上层系统或设备的数据交互。

-可编程性:用户可通过编程语言(如梯形图、结构化文本)自定义控制逻辑。

物理与安装特性

-轻量化设计:净重约1.03公斤,结构紧凑,易于集成到现有设备中。

-安装灵活性:支持导轨或固定安装,适应不同工业布局。

三、应用场景

制造业:电机控制系统、自动化生产线的运动控制。

能源行业:发电机组、变频调速系统的转子位置监测。

化工与石油:旋转机械(如压缩机、泵)的振动与转速监控。

过程控制:温度、压力等参数的闭环调节。

四、设计优势

兼容性:可与ABB及其他制造商设备集成,形成统一自动化平台。

扩展性:通过模块化接口支持功能扩展(如增加I/O通道或通信模块)。

维护便捷性:提供直观的用户界面与诊断工具,降低运维成本。

CB801 3BSE042245R1

CB801 3BSE042245R1

ABB 3ASC25H219B DATX133 is a multifunctional industrial automation component with both rotor feedback and programmable control functions,which is widely used in precision control scenarios in the industrial field.The following is a comprehensive analysis of its core functions and technical features:

I.Product positioning and core functions

Rotor feedback board

-As a rotor position detection and speed feedback module,it is designed for ABB inverters to receive and process rotor signals to achieve high-precision closed-loop feedback of motor control systems.

-High-precision sensor technology:quickly and accurately measure rotor position,and support motor control systems in power,chemical,petroleum,metallurgy and other industries.

Programmable control system components

-Compatible with programmable logic control(PLC),supporting multiple scenarios such as logic control,motion control and temperature control.

-Modular design:It can be expanded to achieve flexible configuration of small to large projects and seamlessly integrate with other ABB products.

II.Technical features

High reliability and stability

-Adopt high-quality electronic components,with anti-interference ability and wide temperature operating range(-40°C to+85°C),suitable for harsh industrial environments.

-Support fault self-diagnosis and quickly locate potential problems.

Communication and programming capabilities

-Digital communication protocols:support Ethernet,Profibus and other protocols to achieve data interaction with upper-level systems or devices.

-Programmability:users can customize control logic through programming languages(such as ladder diagrams,structured text).

Physical and installation characteristics

-Lightweight design:net weight is about 1.03 kg,compact structure,easy to integrate into existing equipment.

-Installation flexibility:support rail or fixed installation,adapt to different industrial layouts.

III.Application scenarios

Manufacturing:motion control of motor control systems and automated production lines.

Energy industry:rotor position monitoring of generator sets and variable frequency speed regulation systems.

Chemical and petroleum:vibration and speed monitoring of rotating machinery(such as compressors and pumps).

Process control:closed-loop regulation of parameters such as temperature and pressure.

IV.Design advantages

Compatibility:can be integrated with ABB and other manufacturers’equipment to form a unified automation platform.

Scalability:support functional expansion(such as adding I/O channels or communication modules)through modular interfaces.

Easy maintenance:Provides an intuitive user interface and diagnostic tools to reduce operation and maintenance costs.