描述

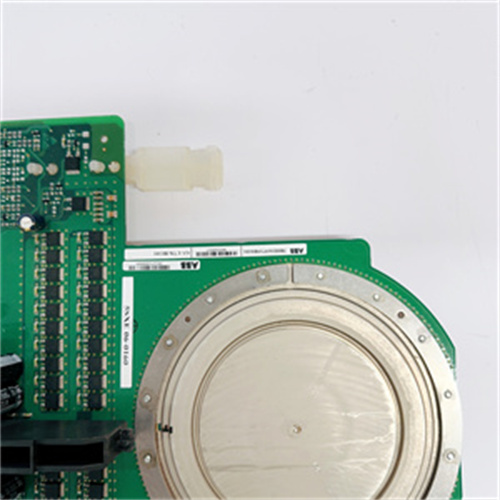

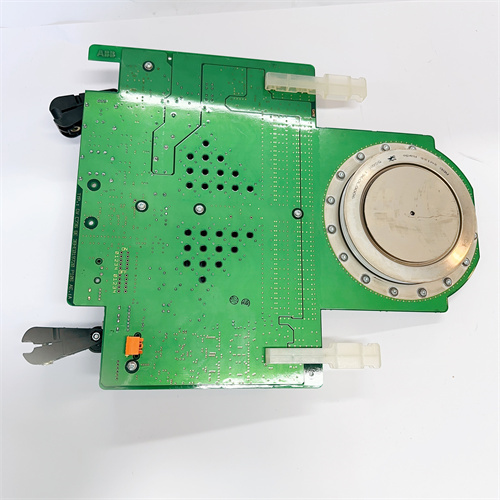

ABB 3BHE024577R0101 PPC907BE模块(以下简称PPC907BE模块)是ABB公司推出的一款高性能工业自动化控制模块,广泛应用于工业控制、过程自动化、能源管理等领域。以下是其核心功能与技术特点的综合解析:

一、核心功能

扩展通信与I/O能力

模拟量/数字量扩展:支持增加模拟量输入/输出(AI/AO)和数字量输入/输出(DI/DO)通道,满足复杂控制场景对信号采集与输出的需求。

通信接口:集成以太网、串口(RS-485/RS-232)、Modbus、PROFINET等协议接口,支持与PLC、DCS系统及上位机无缝通信。

处理器与计算能力

高性能处理器:采用多核架构嵌入式处理器,具备强大的实时计算与并行处理能力,可高效执行复杂控制算法与数据处理任务。

存储与数据管理:内置大容量存储器,支持用户程序、历史数据及配置信息的存储,部分型号支持非易失性存储(如Flash)。

运动与逻辑控制

运动控制:支持位置、速度、力控制等运动模式,适用于机器人、数控机床等精密设备。

逻辑控制:通过可编程逻辑(PLC技术)实现复杂逻辑运算与决策,兼容IEC 61131-3标准编程语言(梯形图、结构化文本等)。

二、技术参数与可靠性

环境适应性

工作温度:-20°C至60°C,防护等级IP67(部分型号),适用于恶劣工业环境。

安装方式:DIN导轨安装,支持热插拔,方便维护与扩展。

电源与保护

宽电压输入:支持24V DC宽电压供电,内置过压、过流保护功能,增强系统稳定性。

冗余设计:部分型号支持冗余电源与通信接口,减少单点故障影响。

尺寸与扩展性

模块尺寸:90 mm×30 mm×25 mm,轻量化设计(0.2 kg),适配紧凑型控制系统。

模块化扩展:可通过扩展槽位连接其他功能模块(如高压板、I/O扩展模块),灵活满足不同规模需求。

三、应用领域

工业自动化:电机驱动控制(如ACS800变频器)、机器人轨迹规划、生产线监控。

能源与电力:变电站自动化、新能源设备数据采集与管理。

基础设施:建筑暖通空调(BACnet协议)、船舶自动化系统。

科研与医疗:精密实验设备控制、医疗机器人定位。

ABB 3BHE024577R0101 PPC907BE module(hereinafter referred to as PPC907BE module)is a high-performance industrial automation control module launched by ABB,which is widely used in industrial control,process automation,energy management and other fields.The following is a comprehensive analysis of its core functions and technical features:

1.Core functions

Extended communication and I/O capabilities

Analog/digital expansion:supports adding analog input/output(AI/AO)and digital input/output(DI/DO)channels to meet the needs of complex control scenarios for signal acquisition and output.

Communication interface:integrated Ethernet,serial port(RS-485/RS-232),Modbus,PROFINET and other protocol interfaces,supporting seamless communication with PLC,DCS system and host computer.

Processor and computing power

High-performance processor:adopts multi-core architecture embedded processor,with powerful real-time computing and parallel processing capabilities,and can efficiently execute complex control algorithms and data processing tasks.

Storage and data management:Built-in large-capacity memory supports storage of user programs,historical data and configuration information.Some models support non-volatile storage(such as Flash).

Motion and logic control

Motion control:Supports motion modes such as position,speed,and force control,suitable for precision equipment such as robots and CNC machine tools.

Logic control:Realize complex logical operations and decisions through programmable logic(PLC technology),compatible with IEC 61131-3 standard programming language(ladder diagram,structured text,etc.).

2.Technical parameters and reliability

Environmental adaptability

Working temperature:-20°C to 60°C,protection level IP67(some models),suitable for harsh industrial environments.

Installation method:DIN rail installation,hot plug support,convenient maintenance and expansion.

Power supply and protection

Wide voltage input:Support 24V DC wide voltage power supply,built-in overvoltage and overcurrent protection functions,enhance system stability.

Redundant design:Some models support redundant power supply and communication interface to reduce the impact of single point failure.

Size and scalability

Module size:90 mm×30 mm×25 mm,lightweight design(0.2 kg),suitable for compact control systems.

Modular expansion:other functional modules(such as high-voltage boards,I/O expansion modules)can be connected through expansion slots to flexibly meet different scale requirements.

III.Application areas

Industrial automation:motor drive control(such as ACS800 inverter),robot trajectory planning,production line monitoring.

Energy and power:substation automation,new energy equipment data collection and management.

Infrastructure:building HVAC(BACnet protocol),ship automation system.

Scientific research and medical:precision laboratory equipment control,medical robot positioning.