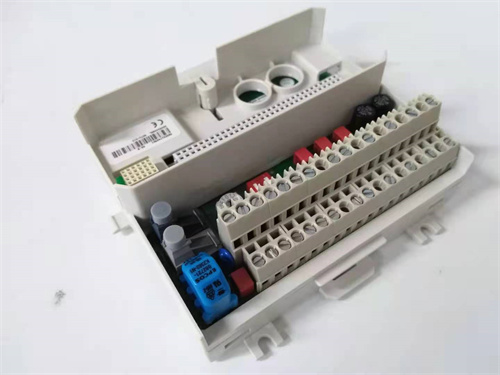

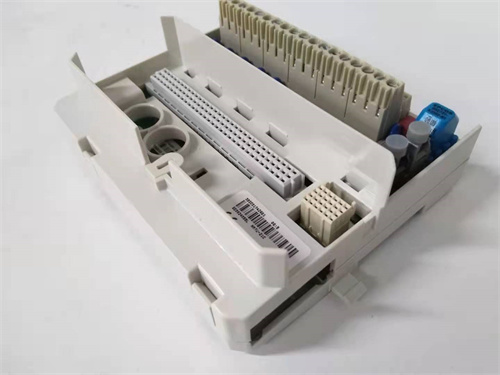

描述

ABB 3BSE017429R1 NMTU-21C是一款专为工业自动化和过程控制设计的热阻功率模块,具有高精度、高可靠性和广泛的兼容性。以下是其核心功能与技术特点的综合概述:

一、核心功能与技术参数

热阻功率测量与监测

用于测量和监控热电阻(如Pt100、Pt50等)的功率和温度,支持高精度数据采集,测量误差范围±0.1%FS(全量程),确保工业过程的稳定性和准确性。

模块化设计

支持多通道输入输出,可灵活扩展以满足不同规模的控制系统需求,适用于分布式控制系统(DCS)和可编程逻辑控制器(PLC)的集成。

通信与协议兼容性

支持Modbus、Profibus等工业通信协议,可无缝对接主流自动化系统。

兼容多种PLC品牌(如西门子、施耐德、通用电气等),方便现有系统的升级与整合。

二、应用场景

工业加热系统

用于监测和控制工业加热炉、热处理设备的温度,优化能源利用并确保工艺参数稳定性。

温度控制领域

在化工、制药、食品加工等行业中,实现对反应釜、干燥设备等的精准温度调控。

电力系统

监测电力设备(如变压器、电机)的运行温度,预防过热故障并延长设备寿命。

环境监测与科学实验

适用于实验室设备温度控制及环境温度实时监测系统。

三、安装与配置

接口类型:支持标准模拟量输入(电压/电流信号)及数字通信接口,方便与传感器和控制器连接。

安装方式:兼容DIN导轨或机架式安装,适应不同工业现场布局需求。

配置工具:提供图形化配置软件,支持参数快速设置及故障诊断功能。

四、优势与特点

高可靠性

工业级防护设计,宽温工作范围(-40°C至85°C),抗电磁干扰能力强,MTBF(平均无故障时间)超过5万小时。

智能扩展性

支持定制化功能开发,可根据需求增加数据存储、远程监控等附加模块。

维护便捷性

提供详细的安装手册及远程技术支持,降低用户维护成本。

五、典型应用案例

化工反应器温度控制:实时监测反应釜内温度,通过PID算法自动调节加热功率,确保化学反应精度。

食品加工生产线:控制烘焙、杀菌设备的温度曲线,保障食品质量一致性。

ABB 3BSE017429R1 NMTU-21C is a thermal resistor power module designed for industrial automation and process control,with high precision,high reliability and wide compatibility.The following is a comprehensive overview of its core functions and technical features:

I.Core functions and technical parameters

Thermal resistor power measurement and monitoring

Used to measure and monitor the power and temperature of thermal resistors(such as Pt100,Pt50,etc.),support high-precision data acquisition,measurement error range±0.1%FS(full scale),to ensure the stability and accuracy of industrial processes.

Modular design

Supports multi-channel input and output,can be flexibly expanded to meet the needs of control systems of different scales,suitable for the integration of distributed control systems(DCS)and programmable logic controllers(PLC).

Communication and protocol compatibility

Supports industrial communication protocols such as Modbus and Profibus,and can seamlessly connect to mainstream automation systems.

Compatible with a variety of PLC brands(such as Siemens,Schneider,General Electric,etc.),convenient for upgrading and integration of existing systems.

2.Application scenarios

Industrial heating system

Used to monitor and control the temperature of industrial heating furnaces and heat treatment equipment,optimize energy utilization and ensure the stability of process parameters.

Temperature control field

In the chemical,pharmaceutical,food processing and other industries,realize accurate temperature control of reactors,drying equipment,etc.

Power system

Monitor the operating temperature of power equipment(such as transformers and motors)to prevent overheating failures and extend equipment life.

Environmental monitoring and scientific experiments

Applicable to laboratory equipment temperature control and environmental temperature real-time monitoring system.

3.Installation and configuration

Interface type:Support standard analog input(voltage/current signal)and digital communication interface,convenient for connection with sensors and controllers.

Installation method:Compatible with DIN rail or rack installation,adapt to different industrial site layout requirements.

Configuration tool:Provide graphical configuration software,support parameter quick setting and fault diagnosis function.

4.Advantages and features

High reliability

Industrial-grade protection design,wide temperature operating range(-40°C to 85°C),strong anti-electromagnetic interference ability,MTBF(mean time between failures)exceeds 50,000 hours.

Intelligent scalability

Supports customized function development,and can add additional modules such as data storage and remote monitoring according to needs.

Easy maintenance

Provide detailed installation manuals and remote technical support to reduce user maintenance costs.

V.Typical application cases

Chemical reactor temperature control:Real-time monitoring of the temperature in the reactor,automatic adjustment of heating power through PID algorithm to ensure chemical reaction accuracy.

Food processing production line:Control the temperature curve of baking and sterilization equipment to ensure food quality consistency.