描述

一、产品定位与核心功能

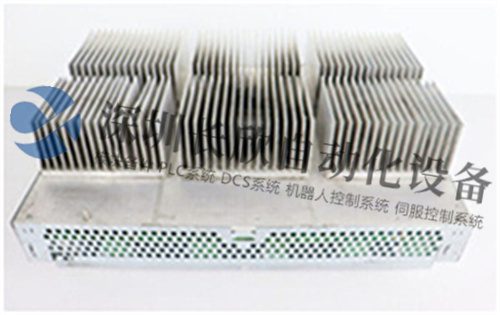

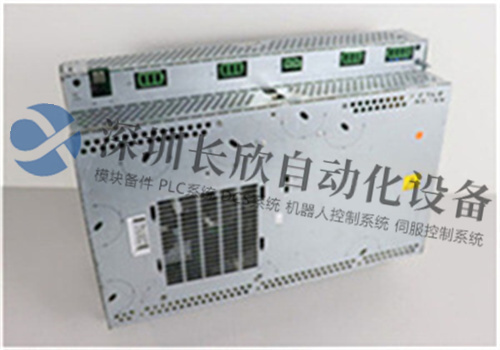

模块类型

-驱动控制器:管理机器人关节电机的电流与扭矩控制,支持多轴协同运动;

-集成通信:兼容EtherCAT、DeviceNet协议,实现高速数据交互。

核心特性

-高精度控制:信号精度±0.1%,支持±10V模拟量输入;

-过载保护:内置温度传感器与短路防护,防止电机烧毁;

-模块化设计:DIN导轨安装,支持热插拔维护。

二、技术参数

|项目|参数/功能|

|电源需求|24V DC(允许波动±15%)|

|输出类型|模拟电压/电流(0–10V/4–20mA)|

|工作温度|-20°C至+60°C(IP20防护)|

|通信接口|以太网、RS-485(支持Modbus/TCP)|

三、应用场景

工业机器人控制

-IRB 120/1terior系列的关节驱动(如焊接、喷涂);

-多轴联动系统的同步控制(如装配、检测)。

自动化产线集成

-与DSQC 652 I/O模块配合,实现产线设备协同;

-恶劣环境下的稳定运行(如化工厂防爆场景)。

1.Product positioning and core functions

Module Type

-Drive controller:manages the current and torque control of the robot joint motor,and supports multi-axis coordinated movement;

-Integrated communication:compatible with EtherCAT and DeviceNet protocols to realize high-speed data interaction.

Core features

-High-precision control:signal accuracy±0.1%,supports±10V analog input;

-Overload protection:built-in temperature sensor and short-circuit protection to prevent the motor from burning;

-Modular design:DIN rail installation,support hot-swap maintenance.

2.Technical parameters

|Project|Parameters/Functions|

|Power requirements|24V DC(permitted fluctuation±15%)|

|Output Type|Analog Voltage/Current(0–10V/4–20mA)|

|Operating temperature|-20°C to+60°C(IP20 protection)|

|Communication interface|Ethernet,RS-485(supports Modbus/TCP)|

III.Application scenarios

Industrial robot control

-joint drives(such as welding,spraying)of the IRB 120/1tier series;

-Synchronous control(such as assembly and detection)of multi-axis linkage system.

Automated production line integration

-Cooperate with DSQC 652 I/O module to achieve production line equipment coordination;

-Stable operation in harsh environments(such as chemical factory explosion-proof scenarios).