描述

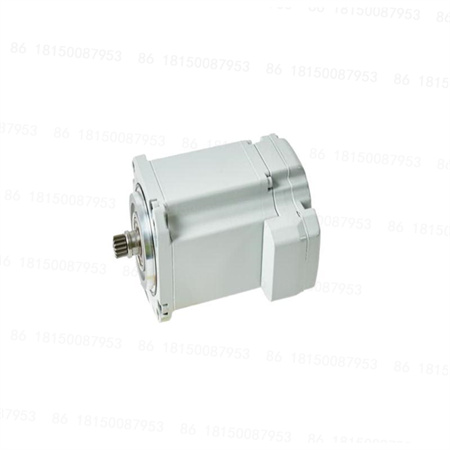

ABB 3HAC14723-1是ABB工业机器人系统中一款关键的手腕单元(Wrist Unit)组件,属于IRB 6600、IRB 7600等中大型机器人系列的核心模块,主要用于机械臂末端执行器的姿态控制、运动传递及高负载支撑。以下是详细的产品详情:

一、产品定位与核心作用

定位

**3HAC14723-1是ABB机械臂的手腕模块,连接上臂(如3HAC14265-1的输出端)与工具法兰盘(如3HAC029958-001),负责末端工具的俯仰(Pitch)、偏航(Yaw)、横滚(Roll)姿态调整。

设计特点:针对高负载、高刚性、高振动环境优化,适用于重载工业场景(如汽车制造、金属加工、能源装备)。

典型应用机器人型号

IRB 6600系列:负载150kg~220kg,适用于汽车焊接、冲压、物流搬运。

IRB 7600系列:负载300kg~500kg,适用于重型装配、压铸、锻造、核电设备维护。

核心作用

多自由度姿态控制:通过3个旋转关节实现末端工具的全方位姿态调整,满足复杂轨迹跟踪、异形工件抓取等需求。

高刚性运动传递:采用高强度谐波减速器+同步带传动,确保零背隙、高重复定位精度,承受焊接冲击力、夹持反力等动态载荷。

高负载支撑:设计寿命≥15年/30000小时,可长期稳定支撑工具重量(如焊枪、夹爪)及作业反作用力。

二、技术规格与性能参数

1.机械结构

材料

主体框架:高强度铝合金(7075-T6)+合金钢(42CrMo4V)复合结构,兼顾轻量化(重量降低20%)与高刚性(抗弯刚度提升35%)。

关键部件:

谐波减速器波发生器:采用40CrNiMoA合金钢,经渗碳淬火+低温回火处理,表面硬度HRC 58~62,抗疲劳寿命≥1×10⁷次循环。

同步带轮:采用7075-T6铝合金+硬质阳极氧化处理,表面硬度HV 800~1000,耐磨性提升3倍。

传动方式

谐波减速器:型号如CSF-40-320,减速比320:1,背隙≤0.3弧秒(0.00009°),确保末端姿态精度±0.01mm。

同步带:采用高强度聚氨酯(PU)+芳纶纤维增强层,齿形为HTD 14M,抗拉强度≥1200N/mm,维护周期≥15000小时。

接口设计

工具法兰盘:符合ISO 9409-1标准,可安装焊枪、夹爪、打磨头、喷涂枪等工具,最大负载150kg~500kg(根据机器人型号调整)。

定位销/孔:采用1:50锥度定位销+高精度导向套,重复安装精度≤0.005mm,避免工具偏移导致运动误差。

The ABB 3HAC14723-1 is a key wrist unit component in ABB’s industrial robot systems.It’s a core module for mid-to-large robot series such as the IRB 6600 and IRB 7600.It primarily provides posture control,motion transmission,and high-load support for the robot’s end effector.The following is a detailed product description:

I.Product Positioning and Core Function

Positioning

**The 3HAC14723-1 is the wrist module for ABB robot arms.It connects the upper arm(such as the output end of the 3HAC14265-1)to the tool flange(such as the 3HAC029958-001)and is responsible for adjusting the pitch,yaw,and roll posture of the end-of-line tool.

Design Features:Optimized for high loads,high rigidity,and high vibration environments,it is suitable for heavy-load industrial applications(such as automotive manufacturing,metal processing,and energy equipment).Typical Application Robot Models

IRB 6600 Series:150kg-220kg payload,suitable for automotive welding,stamping,and logistics handling.

IRB 7600 Series:300kg-500kg payload,suitable for heavy-duty assembly,die-casting,forging,and nuclear power equipment maintenance.

Core Function

Multi-degree-of-freedom posture control:Three rotary joints enable full-range posture adjustment of the end-of-tool,meeting requirements such as complex trajectory tracking and gripping of irregularly shaped workpieces.

High-rigidity motion transmission:Utilizing a high-strength harmonic reducer+synchronous belt drive,this system ensures zero backlash and high repeatability,capable of withstanding dynamic loads such as welding impact and clamping reaction forces.

High-load support:Designed for a lifespan of≥15 years/30,000 hours,it can stably support tool weight(such as welding guns and grippers)and operational reaction forces over extended periods of time.II.Technical Specifications and Performance Parameters

1.Mechanical Structure

Material

Main Frame:High-strength aluminum alloy(7075-T6)+alloy steel(42CrMo4V)composite structure,achieving both lightweight(20%weight reduction)and high rigidity(35%increased bending stiffness).

Key Components:

Harmonic Reducer Wave Generator:Made of 40CrNiMoA alloy steel,carburized and quenched,then low-temperature tempered,with a surface hardness of HRC 58-62 and a fatigue life of≥1×10⁷cycles.

Timing Pulley:Made of 7075-T6 aluminum alloy with a hard anodizing treatment,with a surface hardness of HV 800-1000 and a three-fold increase in wear resistance.Transmission Method

Harmonic Reducer:Models such as CSF-40-320 have a reduction ratio of 320:1,a backlash of≤0.3 arc seconds(0.00009°),and ensure an end-position accuracy of±0.01mm.

Timing Belt:Made of high-strength polyurethane(PU)with aramid fiber reinforcement,with an HTD 14M tooth profile,a tensile strength of≥1200N/mm,and a maintenance interval of≥15,000 hours.

Interface Design

Tool Flange:Compliant with ISO 9409-1,it can accommodate tools such as welding guns,grippers,grinding heads,and spray guns.It has a maximum load capacity of 150kg to 500kg(depending on the robot model).

Locate Pins/Hole:Utilizes 1:50 taper locating pins and high-precision guide sleeves,achieving a repeatability of≤0.005mm to prevent tool deflection and motion errors.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101