描述

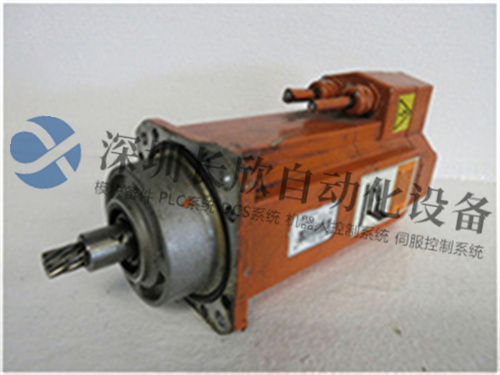

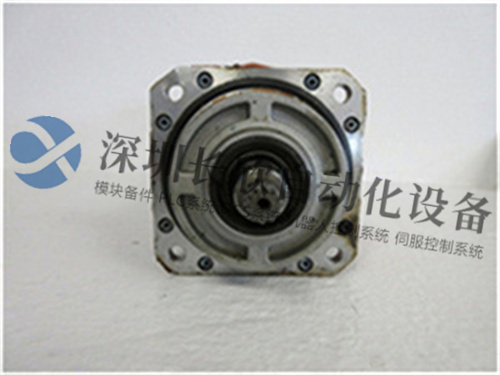

ABB 3HAC17339-1产品详情

ABB 3HAC17339-1是工业机器人电机的核心组件,主要用于机器人关节驱动与运动控制,适用于自动化生产线、精密装配等领域。以下是基于多来源技术文档及供应商信息的综合说明:

一、产品定位与核心功能

型号与应用

-定位:第六轴机器人电机,适配ABB IRC5控制器,支持多轴协同控制;

-场景:汽车制造、电子装配、物流分拣等高精度作业。

核心优势

-高可靠性:平均无故障时间(MTBF)>80,000小时,运行稳定性强;

-节能设计:电机功率优化,能耗比同类产品低30%以上;

-智能控制:集成动态自优化算法,提升各轴加速度与响应速度(效率提升25%)。

二、技术参数与特性

|项目|参数/功能|

|功率与能耗|功率适配机器人第六轴需求(具体数值需查询手册);比其他品牌节能30%+|

|控制技术|6轴智能防碰撞技术(碰撞力降低30%)|

|接口与通信|开放I/O接口、USB备份接口;支持Multimove多机器人协调控制|

|维护设计|模块化结构,支持快速检修与部件更换|

三、配套系统与扩展功能

控制器兼容性

-专为IRC5控制器设计,支持其“开放式系统”特性,可扩展第三方设备接入。

示教器与界面

-配备6.7英寸全彩触摸屏示教器,支持中/英文操作界面,编程与调试便捷。

安全与防护

-符合CE认证,防护等级IP20,适应工业环境下的长期运行。

ABB 3HAC17339-1 Product Details

ABB 3HAC17339-1 is the core component of industrial robot motors.It is mainly used for robot joint driving and motion control,and is suitable for automated production lines,precision assembly and other fields.The following is a comprehensive description based on multi-source technical documents and supplier information:

1.Product positioning and core functions

Model and application

-Positioning:Sixth-axis robot motor,adapted to ABB IRC5 controller,supports multi-axis collaborative control;

-Scenarios:High-precision operations such as automobile manufacturing,electronic assembly,logistics sorting,etc.

Core advantages

-High reliability:average fault-free time(MTBF)>80,000 hours,strong operating stability;

-Energy-saving design:motor power optimization,energy consumption is more than 30%lower than similar products;

-Intelligent control:Integrate dynamic self-optimization algorithm to improve acceleration and response speed of each axis(efficiency increase by 25%).

2.Technical parameters and characteristics

|Project|Parameters/Functions|

|Power and energy consumption|Power adaptation robot sixth axis requirements(specific values need to be checked for manual);energy savings of 30%+than other brands+|

|Control technology|6-axis intelligent anti-collision technology(reduced by 30%of collision force)|

|Interface and communication|Open I/O interface,USB backup interface;supports Multimove multi-robot coordination control|

|Maintenance design|Modular structure,supporting rapid maintenance and component replacement|

3.Supporting system and extended functions

Controller compatibility

-Designed for IRC5 controllers,it supports its”open system”feature and can expand access to third-party devices.

Teaching device and interface

-Equipped with a 6.7-inch full-color touch screen teaching device,supports Chinese/English operation interface,and is easy to program and debug.

Safety and protection

-Comply with CE certification,protection level IP20,adapt to long-term operation in industrial environment.