描述

ABB CI627是一款高性能的工业自动化模块,广泛应用于工厂自动化、过程控制、电力系统等场景,其核心功能与技术特点如下:

一、产品概述

CI627是ABB公司推出的模块化输入输出(I/O)及通信接口模块,支持数据采集、处理与控制逻辑执行。它具备高精度、高可靠性及灵活扩展性,适用于复杂工业环境。

二、核心功能

数据采集与处理

-支持模拟量(电压、电流)和数字量(开关状态、计数器)输入,可处理复杂信号并生成实时数据。

-集成滤波、标定等算法,提升数据准确性。

通信与接口

-支持EtherNet/IP、Modbus TCP/IP、PROFINET等协议,兼容以太网、RS232/485等接口,实现设备间协同控制与数据共享。

-可配置冗余通信链路,确保高可用性。

控制逻辑与算法

-支持PID控制、定时逻辑等高级控制算法,适用于温度调节、流程优化等场景。

-提供可编程接口,允许用户自定义控制逻辑。

冗余与容错

-模块支持热插拔及冗余配置,主备模块自动切换,避免单点故障影响系统运行。

三、技术参数

I/O能力

-标准型号提供2048个I/O端口,可扩展至4096个,满足大规模系统需求。

处理性能

-处理速度达200 MHz,内置1 MB RAM,支持实时数据处理与高速响应。

环境适应性

-工作温度范围-30℃至+70℃,防护等级IP55,抗电磁干扰能力强。

四、应用场景

工厂自动化:连接传感器与执行器,实现生产线监测与控制。

过程控制:化工、石油行业流程变量(温度、压力)监控与调节。

电力系统:变电站设备状态监测及配电系统控制。

建筑自动化:照明、空调等系统的能源管理与优化。

物流仓储:自动化仓库分拣与输送线控制。

五、优势特点

高可靠性:抗干扰设计及故障自恢复机制,确保长期稳定运行。

灵活扩展:模块化结构支持按需添加I/O或通信模块。

开放性:基于.NET架构,兼容多品牌控制器与系统集成。

诊断能力:实时监测系统状态,生成故障报告与报警信息。

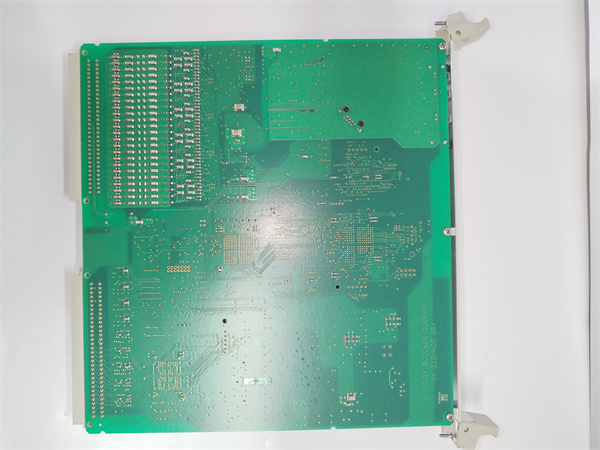

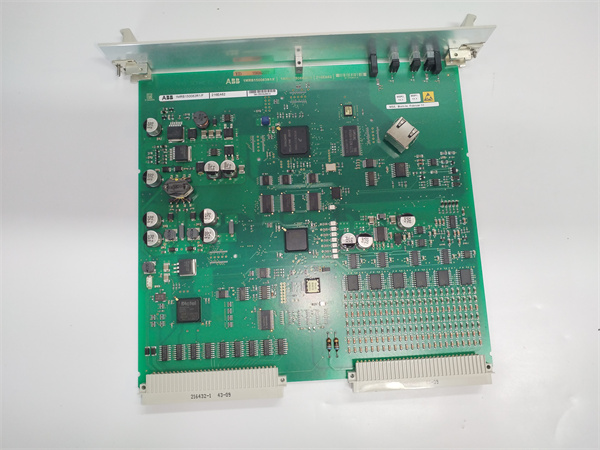

CI627

CI627

ABB CI627 is a high-performance industrial automation module,widely used in factory automation,process control,power system and other scenarios.Its core functions and technical features are as follows:

I.Product Overview

CI627 is a modular input and output(I/O)and communication interface module launched by ABB,which supports data acquisition,processing and control logic execution.It has high precision,high reliability and flexible scalability,suitable for complex industrial environments.

II.Core Functions

Data Acquisition and Processing

-Supports analog(voltage,current)and digital(switch status,counter)inputs,can process complex signals and generate real-time data.

-Integrated filtering,calibration and other algorithms to improve data accuracy.

Communication and Interface

-Supports EtherNet/IP,Modbus TCP/IP,PROFINET and other protocols,compatible with Ethernet,RS232/485 and other interfaces,to achieve collaborative control and data sharing between devices.

-Configurable redundant communication links to ensure high availability.

Control Logic and Algorithms

-Supports advanced control algorithms such as PID control and timing logic,suitable for scenarios such as temperature regulation and process optimization.

-Provides a programmable interface to allow users to customize control logic.

Redundancy and Fault Tolerance

-The module supports hot-swap and redundant configuration,and the main and standby modules automatically switch to avoid single point failures affecting system operation.

III.Technical Parameters

I/O Capacity

-The standard model provides 2048 I/O ports,which can be expanded to 4096 to meet the needs of large-scale systems.

Processing Performance

-The processing speed reaches 200 MHz,with built-in 1 MB RAM,supporting real-time data processing and high-speed response.

Environmental Adaptability

-The operating temperature range is-30℃to+70℃,the protection level is IP55,and it has strong anti-electromagnetic interference ability.

IV.Application Scenarios

Factory Automation:Connect sensors and actuators to realize production line monitoring and control.

Process Control:Monitoring and adjustment of process variables(temperature,pressure)in the chemical and petroleum industries.

Power system:substation equipment status monitoring and distribution system control.

Building automation:energy management and optimization of lighting,air conditioning and other systems.

Logistics warehousing:automated warehouse sorting and conveyor line control.

V.Advantages and features

High reliability:anti-interference design and fault self-recovery mechanism to ensure long-term stable operation.

Flexible expansion:modular structure supports adding I/O or communication modules on demand.

Openness:based on.NET architecture,compatible with multi-brand controllers and system integration.

Diagnostic capabilities:real-time monitoring of system status,generation of fault reports and alarm information.