描述

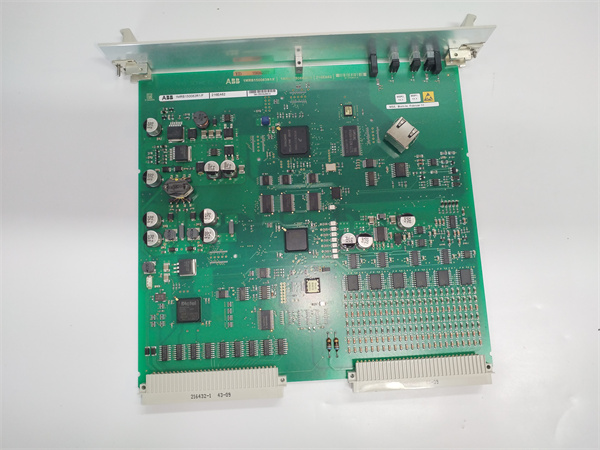

ABB CI627A 3BSE017457R1是一款高性能工业自动化控制模块,集数据采集、通信与处理于一体,广泛应用于制造业、能源、医疗等多个领域。以下是其核心功能与技术特点的综合解析:

一、核心功能

数据采集与处理

支持实时数据采集,兼容Modbus、PROFIBUS-DP、EtherNet/IP等多种协议,可与传感器、PLC等设备无缝连接。

提供2048个I/O端口(可扩展至4096),支持模拟信号(电压/电流)及数字信号(开关量、计数器)的高效处理,适用于复杂工业场景。

通信与接口能力

集成网络接口,支持EtherNet/IP、PROFINET、Modbus TCP/IP等协议,便于系统集成与远程控制。

兼容总线协议(如AF 100、PROFIBUS),可作为独立总线管理员,实现冗余双绞线连接与媒体传播管理。

高级功能

报表生成:自动保存并生成70多个唯一报表,支持数据跟踪与分析。

监测与诊断:实时监控系统状态,检测故障并触发报警,提供诊断信息以优化维护流程。

运动控制:可扩展运动控制功能,适配直流、无刷电机及步进电机,支持嵌入式运动算法与分布式智能分配。

二、技术参数

处理能力:200 MHz主频,1 MB RAM,支持复杂算法与高速响应。

尺寸与安装:DIN导轨式安装,体积紧凑(部分型号如SFS流量模块仅50×40×20 mm)。

环境适应性:宽温设计(-40℃至70℃),抗电磁干扰,符合工业级防护标准。

电源:支持24 V DC供电,冗余电源选项提升可靠性。

三、应用场景

工业自动化:制造业生产线、电力系统监控、建筑自动化等。

医疗设备:集成于医疗气体流量监测系统,响应时间≤20 ms,精度高达2%FS。

环境技术:连续排放监测(CEM)、气体分析仪器等。

能源管理:钢铁轧管、发电厂电气系统远程监控与故障预警。

四、技术优势

高可靠性:故障自恢复机制、冗余设计(如双绞线冗余接口),MTBF超50,000小时。

灵活性:模块化架构支持功能扩展,兼容S800 I/O系统及FOUNDATION Fieldbus。

易用性:无需额外软件编程,支持图形化工具(如易易运动工作室)配置。

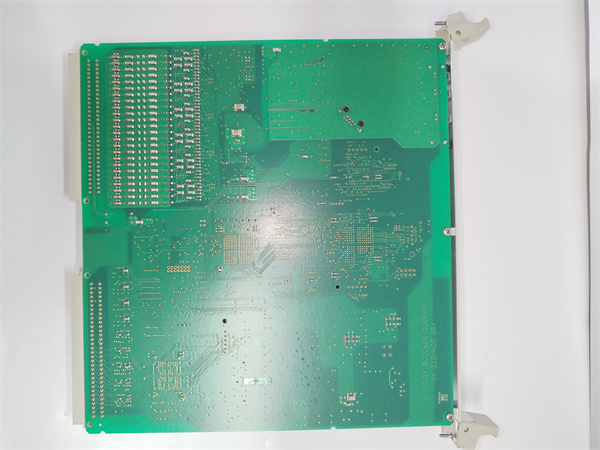

CI627

CI627

ABB CI627A 3BSE017457R1 is a high-performance industrial automation control module that integrates data acquisition,communication and processing.It is widely used in manufacturing,energy,medical and other fields.The following is a comprehensive analysis of its core functions and technical features:

1.Core functions

Data acquisition and processing

Supports real-time data acquisition,compatible with multiple protocols such as Modbus,PROFIBUS-DP,EtherNet/IP,and can be seamlessly connected with sensors,PLCs and other devices.

Provides 2048 I/O ports(expandable to 4096),supports efficient processing of analog signals(voltage/current)and digital signals(switching quantity,counter),suitable for complex industrial scenarios.

Communication and interface capabilities

Integrated network interface,supports EtherNet/IP,PROFINET,Modbus TCP/IP and other protocols,facilitating system integration and remote control.

Compatible with bus protocols(such as AF 100,PROFIBUS),can be used as an independent bus administrator to achieve redundant twisted pair connection and media communication management.

Advanced functions

Report generation:Automatically save and generate more than 70 unique reports,support data tracking and analysis.

Monitoring and diagnosis:Real-time monitoring of system status,detection of faults and triggering of alarms,and provision of diagnostic information to optimize maintenance processes.

Motion control:Expandable motion control functions,adaptable to DC,brushless motors and stepper motors,support embedded motion algorithms and distributed intelligent allocation.

II.Technical parameters

Processing power:200 MHz main frequency,1 MB RAM,support for complex algorithms and high-speed response.

Dimensions and installation:DIN rail installation,compact size(some models such as SFS flow module are only 50×40×20 mm).

Environmental adaptability:wide temperature design(-40℃to 70℃),anti-electromagnetic interference,in line with industrial protection standards.

Power supply:Supports 24 V DC power supply,redundant power supply option to improve reliability.

III.Application scenarios

Industrial automation:manufacturing production lines,power system monitoring,building automation,etc.

Medical equipment:integrated in medical gas flow monitoring system,response time≤20 ms,accuracy up to 2%FS.

Environmental technology:continuous emission monitoring(CEM),gas analysis instruments,etc.

Energy management:remote monitoring and fault warning of steel rolling pipes and power plant electrical systems.

IV.Technical advantages

High reliability:fault self-recovery mechanism,redundant design(such as twisted pair redundant interface),MTBF over 50,000 hours.

Flexibility:modular architecture supports functional expansion,compatible with S800 I/O system and FOUNDATION Fieldbus.

Ease of use:no additional software programming is required,and graphical tools(such as Easy Motion Studio)configuration is supported.