描述

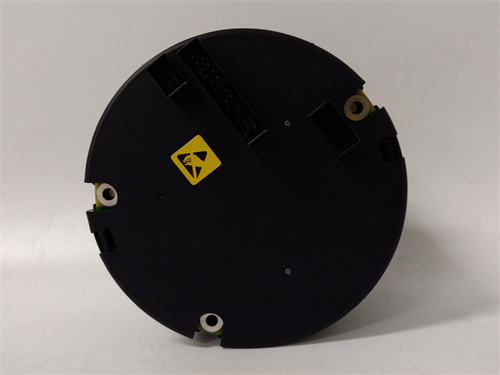

ABB D674A906U01是ABB公司推出的一款高性能工业自动化模块,兼具模拟量输入、处理器及流量测量功能,广泛应用于工业控制、能源管理、智能制造等领域。以下是其核心参数、技术特点及应用场景的综合分析:

1.核心参数与技术规格

输入电源:支持24V DC±20%宽电压输入,适应工业现场电源波动。

I/O点数:提供16通道模拟量输入,支持差分与单端模式,兼容高精度信号采集(如温度、压力、流量)。

通信接口:支持以太网、Modbus TCP/IP等协议,兼容Profibus DP等现场总线,便于系统集成。

处理器性能:计算能力达425%,可运行复杂逻辑控制算法,适配变电站自动化、分布式控制系统等场景。

防护设计:工业级IP防护等级,耐受高温(-30℃至+70℃)、高湿(95%RH)及强电磁干扰环境。

2.核心功能与技术特点

高精度测量:

作为流量计发射器模块时,采用先进传感器技术(如电磁、超声波),支持温度与压力补偿,实现流速数据的高精度实时传输。

灵活编程:

支持IEC 61131-3标准语言(梯形图、结构化文本等),可自定义控制逻辑,满足复杂场景需求。

远程维护:

集成远程诊断功能,支持故障预警与参数配置,降低运维成本。

模块化扩展:

可与ABB其他模块无缝对接,构建分布式控制系统,适应不同规模的工业应用。

3.典型应用场景

工业自动化:

用于PLC系统中,采集传感器信号并执行过程控制,如化工、制药行业的流量监测与工艺优化。

能源管理:

在变电站、发电设备中监测电网参数,支持继电保护与能源调度。

智能制造:

集成于生产线控制系统,提升设备协同效率,例如机器人运动控制或生产数据采集。

基础设施:

应用于水处理、油气输送等领域,确保关键参数(如流量、压力)的精准控制与传输。

4.兼容性与扩展性

协议支持:

支持HART、Profibus、CANopen等工业通信协议,可连接多品牌设备,构建开放的自动化系统。

处理器扩展:

作为变电站自动化系统的处理器模块,可管理局间总线(IBB)通信,处理保护功能及逻辑配置。

传感器适配:

兼容多种传感器类型(如压力、温度、流量传感器),扩展性强。

ABB D674A906U01 is a high-performance industrial automation module launched by ABB.It has analog input,processor and flow measurement functions and is widely used in industrial control,energy management,intelligent manufacturing and other fields.The following is a comprehensive analysis of its core parameters,technical features and application scenarios:

1.Core parameters and technical specifications

Input power supply:supports 24V DC±20%wide voltage input to adapt to power supply fluctuations in industrial sites.

I/O points:provides 16-channel analog input,supports differential and single-ended modes,and is compatible with high-precision signal acquisition(such as temperature,pressure,and flow).

Communication interface:supports Ethernet,Modbus TCP/IP and other protocols,and is compatible with field buses such as Profibus DP,which is convenient for system integration.

Processor performance:The computing power reaches 425%,and it can run complex logic control algorithms,adapting to scenarios such as substation automation and distributed control systems.

Protection design:Industrial-grade IP protection level,resistant to high temperature(-30℃to+70℃),high humidity(95%RH)and strong electromagnetic interference environment.

2.Core functions and technical features

High-precision measurement:

When used as a flowmeter transmitter module,it adopts advanced sensor technology(such as electromagnetic and ultrasonic),supports temperature and pressure compensation,and realizes high-precision real-time transmission of flow rate data.

Flexible programming:

Supports IEC 61131-3 standard language(ladder diagram,structured text,etc.),and can customize control logic to meet the needs of complex scenarios.

Remote maintenance:

Integrated remote diagnosis function,support fault warning and parameter configuration,and reduce operation and maintenance costs.

Modular expansion:

Can be seamlessly connected with other ABB modules to build distributed control systems to adapt to industrial applications of different scales.

3.Typical application scenarios

Industrial automation:

Used in PLC systems to collect sensor signals and perform process control,such as flow monitoring and process optimization in the chemical and pharmaceutical industries.

Energy management:

Monitor grid parameters in substations and power generation equipment,support relay protection and energy scheduling.

Smart manufacturing:

Integrated in production line control systems to improve equipment coordination efficiency,such as robot motion control or production data acquisition.

Infrastructure:

Applied in water treatment,oil and gas transportation and other fields to ensure accurate control and transmission of key parameters(such as flow and pressure).

4.Compatibility and scalability

Protocol support:

Supports industrial communication protocols such as HART,Profibus,CANopen,etc.,can connect multi-brand equipment,and build an open automation system.

Processor expansion:

As a processor module of the substation automation system,it can manage inter-bus(IBB)communication,process protection functions and logic configuration.

Sensor adaptation:

Compatible with various sensor types(such as pressure,temperature,flow sensors),with strong scalability.