描述

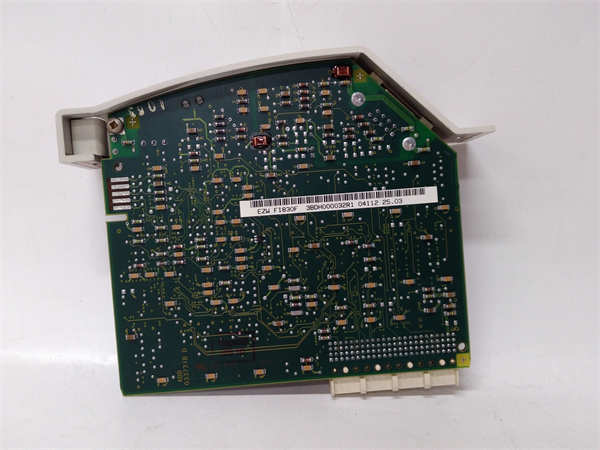

ABB FI830F是一款高性能的现场总线通信模块,广泛应用于工业自动化控制系统中,支持Profibus DP协议,可实现高效的数据传输与设备集成。以下是其核心功能与技术特点的综合解析:

一、核心功能与技术参数

通信协议与接口

Profibus DP接口:符合DIN 19245标准,支持Profibus DP V1协议,传输速率最高可达12 Mbps,适用于高速工业通信场景。

RS485电气隔离接口:提供电气隔离保护,增强抗干扰能力,确保通信稳定性。

网络拓扑与扩展性

支持126个从站:单个模块最多可连接126台Profibus从站设备(如传感器、执行器),满足大型系统扩展需求。

冗余配置:通过冗余AC 800F控制器或外部冗余模块(RLM 01)实现通信链路冗余,提升系统可靠性。

内存与功耗

板载共享内存:提供128 KB共享内存,减少主控制器内存占用。

低功耗设计:典型功耗为2.4 W-2.8 W(取决于通信扫描周期),符合工业节能标准。

诊断与维护

状态指示灯:实时显示模块工作状态(如通信状态、故障报警),简化故障排查。

热插拔支持:无需停机即可更换或维护模块,提升系统可用性。

二、应用场景

工业自动化系统

过程控制:连接HART仪表、变频器、阀门等设备,实现数据采集与控制。

运动控制:支持伺服驱动器通信,实现高精度定位与速度调节。

远程I/O:扩展控制器输入/输出能力,适用于分布式控制系统(DCS)。

行业覆盖

电力与能源:用于发电厂、变电站自动化监控。

石油化工:支持化工生产过程中的仪表组态与数据管理。

制造业:应用于数控机床、机器人控制系统等。

FI830F 3BDH000032R1

FI830F 3BDH000032R1

ABB FI830F is a high-performance fieldbus communication module,widely used in industrial automation control systems,supporting Profibus DP protocol,and can achieve efficient data transmission and device integration.The following is a comprehensive analysis of its core functions and technical features:

I.Core functions and technical parameters

Communication protocol and interface

Profibus DP interface:complies with DIN 19245 standard,supports Profibus DP V1 protocol,and has a transmission rate of up to 12 Mbps,which is suitable for high-speed industrial communication scenarios.

RS485 electrical isolation interface:provides electrical isolation protection,enhances anti-interference ability,and ensures communication stability.

Network topology and scalability

Supports 126 slave stations:A single module can connect up to 126 Profibus slave devices(such as sensors,actuators)to meet the expansion needs of large systems.

Redundant configuration:Communication link redundancy is achieved through redundant AC 800F controllers or external redundancy modules(RLM 01)to improve system reliability.

Memory and power consumption

Onboard shared memory:Provides 128 KB shared memory to reduce the memory usage of the main controller.

Low power design:Typical power consumption is 2.4 W-2.8 W(depending on the communication scan cycle),which meets industrial energy-saving standards.

Diagnosis and maintenance

Status indicator:Real-time display of module working status(such as communication status,fault alarm),simplifying troubleshooting.

Hot-swap support:Modules can be replaced or maintained without downtime,improving system availability.

II.Application scenarios

Industrial automation system

Process control:Connect HART instruments,inverters,valves and other equipment to achieve data acquisition and control.

Motion control:Support servo drive communication to achieve high-precision positioning and speed regulation.

Remote I/O:Expand the controller input/output capabilities,suitable for distributed control systems(DCS).

Industry coverage

Power and energy:Used for power plants and substation automation monitoring.

Petrochemical:Support instrument configuration and data management in chemical production processes.

Manufacturing:Applied to CNC machine tools,robot control systems,etc.