描述

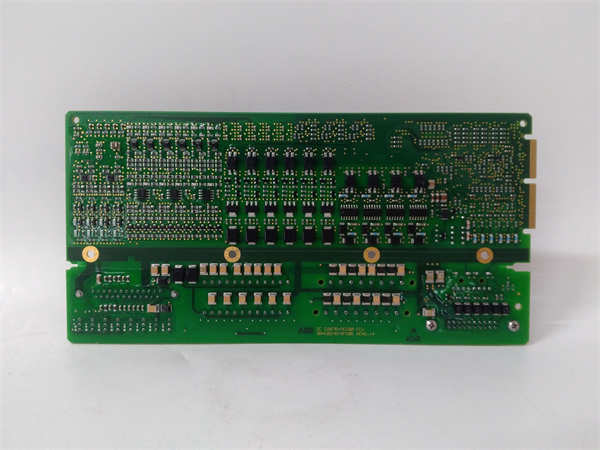

ABB GCC960C103是一款多功能工业模块,广泛应用于自动化控制、电力系统、通信网络等多个领域,其核心功能与技术特点如下:

一、核心功能与技术特点

工业通信与网络支持

-以太网APL模块:作为过程工业的通信核心,支持以太网高级物理层(APL)标准,适用于危险区域的端到端数字通信。

-协议兼容性:内置PROFINET协议栈,支持HART和Modbus设备的无缝迁移,无需代码编写即可实现行为配置。

电力质量控制

-CPU整流器:采用PWM与DSP技术,将交流电转换为可控直流电,适用于钢铁、石化等行业的精密电力控制,具备高效、低占地、长寿命等特点。

端子与人机交互

-端子夹紧模块:提供稳定可靠的电气连接,适用于严苛工业环境。

-触摸屏集成:兼容Panel 800系列HMI,支持TFT/LED显示与多协议通信,适用于复杂流程监控。

二、应用场景

工业自动化

-伺服控制系统(机床、包装设备)、机器人关节控制、半导体制造中的精密定位。

电力系统

-高压变频器、UPS电源、新能源并网设备的电力调节。

通信网络

-工业物联网(IIoT)数据采集、远程设备管理、危险区域传感器通信。

人机界面

-工厂车间操作终端、智能仪表盘、设备运维监控平台。

三、技术优势

高可靠性:通过EMC及环境测试,支持ATEX/IECEx认证,适用于极端工况。

开放性与扩展性:支持Modbus、PROFINET等协议,可与主流PLC及DCS系统集成。

智能化设计:预装应用软件与数据模型,简化配置流程。

四、与其他型号的差异

通信模块:侧重工业网络协议与危险区域适配,对标同类模块性能更优。

电力模块:相比传统整流器,效率提升15%以上,体积缩小30%。

端子模块:采用压铸铝外壳,防护等级IP65,抗振性能更强。

GCD207B101 3BHE024642R0101

IS215WETAH1BB

ABB GCC960C103 is a multifunctional industrial module,widely used in automation control,power system,communication network and other fields.Its core functions and technical features are as follows:

I.Core functions and technical features

Industrial communication and network support

-Ethernet APL module:As the communication core of process industry,it supports Ethernet Advanced Physical Layer(APL)standard and is suitable for end-to-end digital communication in hazardous areas.

-Protocol compatibility:Built-in PROFINET protocol stack,supports seamless migration of HART and Modbus devices,and can realize behavior configuration without code writing.

Power quality control

-CPU rectifier:Using PWM and DSP technology to convert AC power into controllable DC power,it is suitable for precision power control in steel,petrochemical and other industries,with high efficiency,low footprint and long life.

Terminal and human-machine interaction

-Terminal clamping module:Provides stable and reliable electrical connection,suitable for harsh industrial environments.

-Touch screen integration:Compatible with Panel 800 series HMI,supports TFT/LED display and multi-protocol communication,suitable for complex process monitoring.

2.Application scenarios

Industrial automation

-Servo control systems(machine tools,packaging equipment),robot joint control,precision positioning in semiconductor manufacturing.

Power system

-High-voltage inverters,UPS power supplies,power regulation of new energy grid-connected equipment.

Communication network

-Industrial Internet of Things(IIoT)data acquisition,remote equipment management,hazardous area sensor communication.

Human-machine interface

-Factory workshop operation terminal,smart dashboard,equipment operation and maintenance monitoring platform.

3.Technical advantages

High reliability:Passed EMC and environmental tests,supports ATEX/IECEx certification,suitable for extreme working conditions.

Openness and scalability:Supports Modbus,PROFINET and other protocols,and can be integrated with mainstream PLC and DCS systems.

Intelligent design:pre-installed application software and data models to simplify the configuration process.

4.Differences from other models

Communication module:Focuses on industrial network protocols and hazardous area adaptation,and has better performance than similar modules.

Power module:Compared with traditional rectifiers,the efficiency is increased by more than 15%and the volume is reduced by 30%.

Terminal module:Die-cast aluminum housing,protection grade IP65,and stronger vibration resistance.