描述

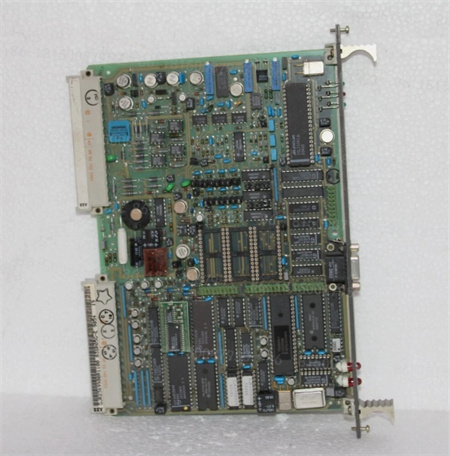

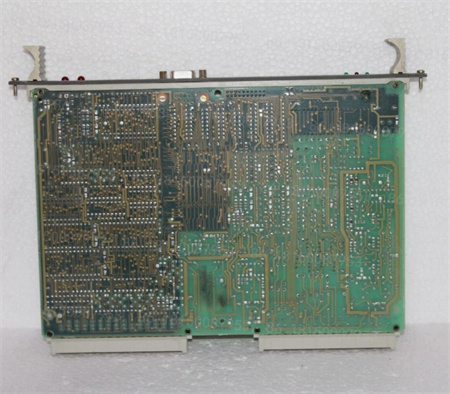

ABB GJR2369900R1100 83SR05E是一款专为工业自动化设计的高速计数器模块,主要用于高精度脉冲信号采集与实时控制。以下是基于行业逻辑和现有线索的综合分析:

一、核心功能与技术特性

高速计数能力

作为83SR系列成员,该模块支持高频脉冲信号输入,适用于电机编码器、旋转传感器等设备的位置/速度监测。参考同系列模块(如83SR04),其计数频率可能达到kHz级别,满足机床、机器人等对动态响应要求高的场景。

多通道并行处理

推测具备多通道独立计数功能(如4-8通道),可同时监测多个轴的运动状态,例如在多轴联动加工中心中实现同步控制。

工业级可靠性

供电设计:采用24V DC工业标准电源,兼容主流PLC/DCS系统。

防护等级:预计达到IP20标准,可防止固体异物侵入,适应工厂环境中的粉尘与振动。

抗干扰能力:通过EMC测试,能耐受变频器、电机等设备产生的电磁干扰。

通信接口

可能支持以下协议:

工业总线:Profinet、Modbus RTU(参考GJR系列其他模块)。

串口通信:RS-485或RS-232,用于与上位机或控制器进行数据交互。

二、应用场景

机床与机器人控制

用于数控机床的主轴定位、机器人关节位置反馈,确保加工精度和运动轨迹的准确性。例如,在汽车零部件加工中,实时监测伺服电机的脉冲信号以实现微米级定位。

包装与物流自动化

在高速包装机中,通过计数传感器信号控制包装材料的进给长度;在AGV(自动导引车)中,结合编码器实现路径追踪与导航。

过程自动化

在化工或制药行业,用于计量泵的脉冲计数以精确控制流体流量,或在输送带系统中监测产品通过量。

三、物理与环境参数推测

尺寸与安装

参考GJR系列模块的通用设计,尺寸可能为234mm(长)×99mm(宽)×60mm(高),采用DIN导轨安装,便于快速集成与维护。

工作环境

温度范围:-20°C至+70°C(适应工业现场的宽温变化)。

存储温度:-40°C至+85°C,支持长期存储。

The ABB GJR2369900R1100 83SR05E is a high-speed counter module designed specifically for industrial automation,primarily used for high-precision pulse signal acquisition and real-time control.The following is a comprehensive analysis based on industry logic and existing clues:

I.Core Functions and Technical Features

High-Speed Counting Capability

As a member of the 83SR series,this module supports high-frequency pulse signal input,making it suitable for position/speed monitoring in devices such as motor encoders and rotary sensors.Compared to modules in the same series(such as the 83SR04),its counting frequency may reach the kHz level,meeting the requirements for dynamic response in applications such as machine tools and robots.

Multi-Channel Parallel Processing

It is speculated to have multi-channel independent counting capabilities(e.g.,4-8 channels),enabling simultaneous monitoring of the motion status of multiple axes,such as in multi-axis machining centers,enabling synchronized control.

Industrial-Grade Reliability

Power Supply Design:Utilizes an industrial-standard 24V DC power supply,compatible with mainstream PLC/DCS systems.

Protection Rating:Expected to meet IP20 standards,it protects against solid foreign objects and withstands the dust and vibration of factory environments.Interference Resistance:Passed EMC testing and can withstand electromagnetic interference generated by devices such as inverters and motors.

Communication Interface

The following protocols may be supported:

Industrial Bus:Profinet,Modbus RTU(see other GJR series modules).

Serial Communication:RS-485 or RS-232,used for data exchange with a host computer or controller.

II.Application Scenarios

Machine Tool and Robot Control

Used for spindle positioning of CNC machine tools and position feedback of robot joints to ensure machining accuracy and motion trajectory accuracy.For example,in automotive parts processing,real-time monitoring of servo motor pulse signals enables micron-level positioning.

Packaging and Logistics Automation

In high-speed packaging machines,counting sensor signals controls the feeding length of packaging materials.In AGVs(Automated Guided Vehicles),encoders are combined for path tracking and navigation.

Process Automation

In the chemical and pharmaceutical industries,pulse counting in metering pumps is used to precisely control fluid flow,or to monitor product throughput in conveyor systems.III.Physical and Environmental Parameters

Dimensions and Installation

Based on the general design of the GJR series modules,the dimensions are 234mm(length)×99mm(width)×60mm(height).DIN rail mounting is used for quick integration and maintenance.

Operating Environment

Temperature Range:-20°C to+70°C(accommodates wide temperature fluctuations in industrial sites).

Storage Temperature:-40°C to+85°C,supporting long-term storage.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101