描述

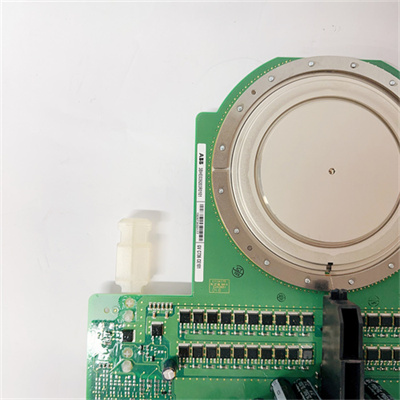

ABB GVC736CE101产品详情

一、基本信息

品牌:ABB(全球电气与自动化技术领导厂商,专注于工业自动化、能源管理、机器人等领域)

型号:GVC736CE101

类型:AC500系列PLC(可编程逻辑控制器)扩展I/O模块——数字量输入模块

用途:作为ABB AC500系列PLC的扩展组件,用于采集工业现场的数字量信号(如按钮、限位开关、传感器触点状态),广泛应用于水处理、楼宇自动化、轨道交通、食品饮料等高可靠性工业场景。

二、技术规格

1.核心功能

输入通道与信号类型:

通道数:16通道数字量输入(单端输入,支持干接点或湿接点信号)。

输入信号:

电压范围:24VDC(兼容NPN/PNP传感器,通过模块配置选择信号类型)。

输入阻抗:≥3kΩ(干接点模式),避免对外部电路造成负载。

滤波时间:可配置(0.5ms/1ms/2ms/4ms),消除信号抖动或噪声干扰。

隔离与防护:

通道隔离:光电隔离,隔离电压≥500V(通道间/通道对地),防止信号干扰或接地回路问题。

过压保护:每通道内置TVS二极管,承受瞬态过压≥100V(1ms脉冲),保护模块免受雷击或浪涌损害。

2.硬件参数

接口与连接:

接线端子:采用可拆卸弹簧端子(支持带电插拔),兼容0.2-2.5mm²线径,接线方便且牢固。

通信接口:通过AC500背板总线与PLC主控单元连接,支持热插拔(需系统配置),模块故障时可在线更换。

电源要求:24VDC(±10%),功耗<2.5W(满载时),支持冗余电源输入(需选配AC500冗余电源模块)。

防护等级与可靠性:

防护等级:IP20(控制柜内安装),外壳材质为阻燃塑料(UL94 V-0),抗电磁干扰(EMC)符合IEC 61131-2标准。

环境适应性:

工作温度:-20℃至+60℃(标准版),-40℃至+70℃(宽温版可选)。

抗振动:符合IEC 60068-2-6标准(10-500Hz,5G),适用于车载或移动设备。

3.性能指标

响应时间与精度:

信号采样时间:≤1ms(典型值),满足高速控制需求(如包装机、分拣线)。

输入延迟:<0.1ms(固定值),确保实时性。

诊断与自检:

内置自诊断功能,可检测通道故障(开路、短路、过压)、电源异常,并通过LED指示灯或PLC报警。

支持通道状态监控(通过ABB Automation Builder软件),实时查看输入信号状态与历史记录。

三、应用领域

水处理与环保

泵站自动化:采集水泵运行状态、液位信号,实现远程启停与故障诊断。

污水处理:连接流量计、浊度计的数字输出信号,触发报警或联锁控制。

楼宇自动化

空调系统控制:采集温湿度传感器、风阀状态信号,优化能耗管理。

安防监控:连接门禁开关、红外传感器,实现入侵检测与报警。

轨道交通

列车控制:采集车门状态、紧急制动按钮信号,实现列车安全联锁。

信号系统:连接轨道电路、信号机触点,确保列车运行安全。

ABB GVC736CE101 Product Details

I.Basic Information

Brand:ABB(a global leader in electrical and automation technology,focusing on industrial automation,energy management,robotics and other fields)

Model:GVC736CE101

Type:AC500 series PLC(programmable logic controller)expansion I/O module-digital input module

Purpose:As an expansion component of ABB AC500 series PLC,it is used to collect digital signals(such as buttons,limit switches,sensor contact status)at industrial sites,and is widely used in high-reliability industrial scenarios such as water treatment,building automation,rail transit,food and beverage.

II.Technical Specifications

1.Core Functions

Input Channels and Signal Types:

Number of Channels:16-channel digital input(single-ended input,supporting dry contact or wet contact signals).

Input Signal:

Voltage Range:24VDC(compatible with NPN/PNP sensors,select signal type through module configuration).

Input Impedance:≥3kΩ(dry contact mode),to avoid loading external circuits.

Filter time:configurable(0.5ms/1ms/2ms/4ms),eliminating signal jitter or noise interference.

Isolation and protection:

Channel isolation:optoelectronic isolation,isolation voltage≥500V(between channels/channel to ground),preventing signal interference or ground loop problems.

Overvoltage protection:Each channel has a built-in TVS diode,which can withstand transient overvoltage≥100V(1ms pulse)to protect the module from lightning or surge damage.

2.Hardware parameters

Interface and connection:

Terminal block:removable spring terminal(supports live plugging and unplugging),compatible with 0.2-2.5mm²wire diameter,convenient and firm wiring.

Communication interface:connected to the PLC main control unit through the AC500 backplane bus,supports hot plugging(system configuration required),and can be replaced online when the module fails.

Power supply requirements:24VDC(±10%),power consumption<2.5W(at full load),supports redundant power input(AC500 redundant power supply module required).

Protection level and reliability:

Protection level:IP20(installed in the control cabinet),the shell material is flame-retardant plastic(UL94 V-0),and the electromagnetic interference(EMC)resistance complies with the IEC 61131-2 standard.

Environmental adaptability:

Operating temperature:-20℃to+60℃(standard version),-40℃to+70℃(wide temperature version optional).

Vibration resistance:complies with the IEC 60068-2-6 standard(10-500Hz,5G),suitable for vehicle-mounted or mobile devices.

3.Performance indicators

Response time and accuracy:

Signal sampling time:≤1ms(typical value),meeting high-speed control requirements(such as packaging machines,sorting lines).

Input delay:<0.1ms(fixed value),ensuring real-time performance.

Diagnosis and self-test:

Built-in self-diagnosis function can detect channel faults(open circuit,short circuit,overvoltage),power supply abnormalities,and alarm through LED indicators or PLC.

Support channel status monitoring(through ABB Automation Builder software),real-time viewing of input signal status and history.

3.Application fields

Water treatment and environmental protection

Pump station automation:collect water pump operation status and liquid level signals to achieve remote start and stop and fault diagnosis.

Sewage treatment:connect the digital output signals of flow meter and turbidity meter to trigger alarm or interlock control.

Building automation

Air conditioning system control:collect temperature and humidity sensors,air valve status signals to optimize energy consumption management.

Security monitoring:connect access control switches and infrared sensors to achieve intrusion detection and alarm.

Rail transportation

Train control:collect door status and emergency brake button signals to achieve train safety interlocking.

Signal system:connect track circuits and signal machine contacts to ensure safe train operation.