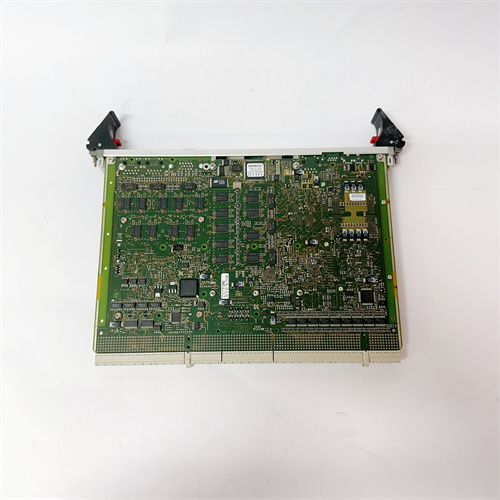

描述

ABB INSUMMCU2 MCU2A02V24是一款专为小型交流电机设计的智能电机控制单元(IMC),集成了高精度控制与全面保护功能,适用于工业自动化、HVAC系统、电动车辆等场景。以下是其核心功能与技术特点的综合解析:

一、核心功能与技术参数

电机控制与保护

-控制模式:支持开环与闭环控制,可调节速度、转矩及响应时间,满足不同工况需求。

-保护机制:内置过载、过压、欠压和短路保护,确保电机安全运行;软启动/软停车功能可减少机械冲击。

电气规格

-电压范围:208-240 VAC

-额定电流:10 A

-通信接口:RS-485与Modbus RTU协议,便于与上位机系统集成。

设计优势

-紧凑性:体积小巧,适配空间受限的设备(如家用电器、工业机械)。

-可靠性:采用ABB工业级设计,防护等级未明确标注(需结合具体型号)。

二、技术架构与工作原理

模块化结构

-控制板:由主控芯片(DSP或FPGA)、CAN网络、采样电路、旋变电路及电源电路组成,负责算法处理与逻辑判断。

-驱动板:集成逆变器与IGBT模块,将直流电转换为三相交流电,驱动电机运行。

逆变器与IGBT协同工作

-逆变器通过控制IGBT的开关状态实现直流到交流的转换,电机控制器根据车辆指令(如油门、刹车)调节电流,控制电机转速与扭矩。

-在电动汽车中,可实现能量回收(将制动能量存储至电池)。

三、应用场景

工业自动化

-适用于风扇、泵、传送机等设备的控制,优化能源效率与系统稳定性。

-兼容HVAC系统(如空调风机),支持远程监控与故障诊断。

电动车辆

-控制电机方向、速度及响应时间,支持档位切换与能量回收功能。

-适配电动自行车、低速电动车等轻型交通工具。

家用与商业设备

-用于厨房设备、家用电器的电机驱动,提升产品性能与用户体验。

ABB INSUMMCU2 MCU2A02V24 is an intelligent motor control unit(IMC)designed for small AC motors.It integrates high-precision control and comprehensive protection functions and is suitable for industrial automation,HVAC systems,electric vehicles and other scenarios.The following is a comprehensive analysis of its core functions and technical features:

I.Core functions and technical parameters

Motor control and protection

-Control mode:supports open-loop and closed-loop control,and can adjust speed,torque and response time to meet different working conditions.

-Protection mechanism:built-in overload,overvoltage,undervoltage and short-circuit protection to ensure safe operation of the motor;soft start/soft stop function can reduce mechanical shock.

Electrical specifications

-Voltage range:208-240 VAC

-Rated current:10 A

-Communication interface:RS-485 and Modbus RTU protocol,easy to integrate with the host system.

Design advantages

-Compactness:small size,suitable for space-constrained equipment(such as household appliances,industrial machinery).

-Reliability:ABB industrial-grade design is adopted,and the protection level is not clearly marked(need to be combined with the specific model).

2.Technical architecture and working principle

Modular structure

-Control board:It is composed of the main control chip(DSP or FPGA),CAN network,sampling circuit,resolver circuit and power supply circuit,responsible for algorithm processing and logical judgment.

-Driver board:Integrates inverter and IGBT module to convert DC power into three-phase AC power to drive the motor to run.

Inverter and IGBT work together

-The inverter realizes the conversion from DC to AC by controlling the switching state of IGBT.The motor controller adjusts the current according to the vehicle command(such as throttle,brake)to control the motor speed and torque.

-In electric vehicles,energy recovery can be achieved(storing braking energy in the battery).

3.Application scenarios

Industrial automation

-Suitable for the control of equipment such as fans,pumps,conveyors,etc.,to optimize energy efficiency and system stability.

-Compatible with HVAC systems(such as air conditioning fans),supporting remote monitoring and fault diagnosis.

Electric vehicles

-Control motor direction,speed and response time,support gear switching and energy recovery functions.

-Suitable for light vehicles such as electric bicycles and low-speed electric vehicles.

Household and commercial equipment

-Used for motor drive of kitchen equipment and household appliances to improve product performance and user experience.