描述

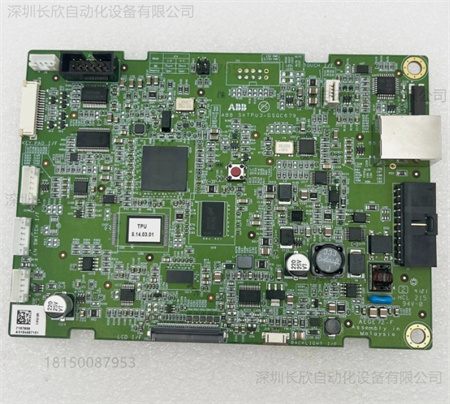

ABB IRC5 3HAC025338-006-09B的详细产品解析,结合ABB机器人控制器命名规则、技术规格及典型应用场景进行专业分析:

一、产品概述

品牌与系列

ABB:全球工业机器人及自动化解决方案领导者,产品覆盖焊接、搬运、涂装、装配等全场景。

IRC5系列:ABB第四代机器人控制器,2004年推出,以高可靠性、强扩展性、易用性为核心设计目标,支持ABB全系列工业机器人(如IRB 2400、IRB 6600、IRB 7600等)。

型号解析:

3HAC025338-006:ABB内部物料编码,唯一标识该控制器硬件版本及配置。

-09B:可能表示软件版本(如09B为功能增强版)或硬件修订号(如改进散热设计或接口兼容性)。

定位与用途

IRC5 3HAC025338-006-09B是ABB IRC5系列的标准型控制器,适用于:

中大型机器人系统:如汽车车身点焊、弧焊、搬运(负载≤800kg)。

多机器人协同控制:支持最多4台机器人同步作业(需选配MultiMove功能包)。

复杂工艺集成:结合ABB Process Control功能,实现焊接参数实时调整、涂胶轨迹优化等。

二、核心硬件规格

处理器与性能

主控单元:

采用Intel Core i7双核处理器(主频≥2.5GHz),支持多任务并行处理(如运动控制、I/O通信、视觉处理)。

实时操作系统(RTOS):基于VxWorks,确保控制周期≤1ms(抖动≤50μs),满足高速运动需求。

运动控制单元:

专用DSP(数字信号处理器)阵列,负责机器人逆运动学计算、轨迹插补及动力学补偿,单轴控制精度≤±0.01mm。

内存与存储

RAM:≥4GB DDR3,支持大型程序运行(如复杂焊接路径、多机器人协同逻辑)。

存储:

系统盘:128GB SSD(预装RobotStudio软件及系统镜像)。

用户盘:1TB HDD(存储程序、工艺参数、历史数据)。

扩展存储:支持USB 3.0接口(最大2TB)及SD卡插槽(最大64GB),用于快速程序备份或数据导出。

接口与扩展性

以太网接口:

2×1000Mbps端口,支持链路聚合(Link Aggregation)及冗余(如HSR/PRP),确保通信可靠性。

协议支持:Modbus TCP、OPC UA(Server/Client)、PROFINET IO Controller/Device、EtherNet/IP。

现场总线接口:

DeviceNet主站:支持最多64个从站设备(如I/O模块、传感器),通信速率≤500kbps。

PROFIBUS-DP主站:支持最多124个从站,通信速率≤12Mbps(适用于旧式设备集成)。

专用接口:

机器人接口:6×高速同步接口(SSI),支持ABB SafeMove2安全功能(如碰撞检测、速度监控)。

视觉接口:1×GigE Vision接口(兼容Basler、Cognex等工业相机),支持实时图像处理(如工件定位、缺陷检测)。

I/O扩展:

本地I/O:32×DI(24V DC)、32×DO(24V DC)、8×AI(4-20mA/0-10V)、4×AO(4-20mA/0-10V)。

分布式I/O:通过EtherCAT或PROFINET连接远程I/O站(如Beckhoff EK1100系列),支持千点级I/O管理。

A detailed product analysis of the ABB IRC5 3HAC025338-006-09B,combining ABB robot controller naming conventions,technical specifications,and typical application scenarios:

I.Product Overview

Brand and Series

ABB:A global leader in industrial robotics and automation solutions,with products covering welding,handling,painting,assembly,and other applications.

IRC5 Series:ABB’s fourth-generation robot controller,launched in 2004.Designed with high reliability,strong scalability,and ease of use as core goals,it supports the full range of ABB industrial robots(such as the IRB 2400,IRB 6600,and IRB 7600).

Model Explanation:

3HAC025338-006:ABB internal material code,uniquely identifying the controller’s hardware version and configuration.

-09B:May indicate a software version(e.g.,09B indicates a feature enhancement)or a hardware revision number(e.g.,improved thermal design or interface compatibility).Positioning and Application

The IRC5 3HAC025338-006-09B is a standard controller in the ABB IRC5 series,suitable for:

Medium-to-large robot systems:such as automotive body spot welding,arc welding,and handling(loads≤800 kg).

Multi-robot collaborative control:Supports simultaneous operation of up to four robots(requires the optional MultiMove function package).

Complex process integration:Combined with ABB Process Control functions,it enables real-time adjustment of welding parameters,glue application trajectory optimization,and more.

II.Core Hardware Specifications

Processor and Performance

Main Control Unit:

Equipped with an Intel Core i7 dual-core processor(clocked at≥2.5 GHz),it supports multi-tasking parallel processing(such as motion control,I/O communication,and vision processing).

Real-time Operating System(RTOS):Based on VxWorks,it ensures a control cycle of≤1 ms(jitter≤50μs),meeting high-speed motion requirements.

Motion Control Unit:

A dedicated DSP(digital signal processor)array is responsible for robot inverse kinematics calculations,trajectory interpolation,and dynamic compensation,achieving single-axis control accuracy of≤±0.01 mm.Memory and Storage

RAM:≥4GB DDR3,supporting large programs(such as complex welding paths and multi-robot collaborative logic).

Storage:

System Disk:128GB SSD(pre-installed with RobotStudio software and system image).

User Disk:1TB HDD(storing programs,process parameters,and historical data).

Expanded Storage:Supports USB 3.0 port(up to 2TB)and SD card slot(up to 64GB)for fast program backup or data export.

Interfaces and Expandability

Ethernet Interface:

2 x 1000Mbps ports,supporting link aggregation and redundancy(such as HSR/PRP)to ensure communication reliability.

Protocol Support:Modbus TCP,OPC UA(Server/Client),PROFINET IO Controller/Device,EtherNet/IP.

Fieldbus Interface:

DeviceNet Master:Supports up to 64 slave devices(such as I/O modules and sensors),with a communication rate of≤500kbps.PROFIBUS-DP Master:Supports up to 124 slaves,with a communication rate of≤12 Mbps(suitable for integration with legacy devices).

Dedicated Interfaces:

Robot Interface:6 high-speed synchronous interfaces(SSI),supporting ABB SafeMove2 safety functions(such as collision detection and speed monitoring).

Vision Interface:1 GigE Vision interface(compatible with industrial cameras from Basler and Cognex),supporting real-time image processing(such as workpiece positioning and defect detection).

I/O Expansion:

Local I/O:32 DI(24V DC),32 DO(24V DC),8 AI(4-20mA/0-10V),4 AO(4-20mA/0-10V).

Distributed I/O:Connects to remote I/O stations(such as the Beckhoff EK1100 series)via EtherCAT or PROFINET,supporting 1,000-point I/O management.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101