描述

ABB KUC720AE01是一款高性能变频器,基于直接转矩控制(DTC)技术设计,广泛应用于工业自动化领域。以下是其核心功能与技术特点的综合解析:

一、核心技术与性能

直接转矩控制(DTC)

采用DTC技术实现电机速度与转矩的精准控制,响应时间达毫秒级,支持零转速时满转矩输出,适用于频繁启停或高动态负载场景。

宽功率覆盖与灵活性

提供广泛的功率范围,兼容多种工业应用需求,支持位势负载(如起重机、电梯)、系统传动及精密控制(如转角/位移调节)。

内置PID控制器

集成PID功能,简化控制系统设计并降低硬件成本,适用于闭环位置、速度或温度调节。

二、功能特点

智能电机管理

电机辨识功能:通过IDRUN自动识别电机参数,优化控制性能。

转矩自适应:在磁通优化模式下,自动调整电机磁通以提高效率并降低噪音,效率提升可达1%-10%。

保护与可靠性

提供过载保护、短路保护及温度保护,支持冗余通信模块以增强系统稳定性。

支持自诊断功能,通过LED指示灯实时反馈运行状态及故障信息。

扩展性与通信接口

集成以太网、Profibus、Modbus等协议,支持与PLC、SCADA等系统的无缝对接。

提供5路可编程输出控制端,灵活适配不同应用场景需求。

三、行业应用案例

钢铁冶金领域

在中间包电磁搅拌(EMS)系统中,KUC720AE01通过非接触式电磁技术实现钢水均匀化,显著提升钢质量并减少夹杂物,应用于多流连铸工艺。

电力系统

配合励磁控制模块,用于发电机励磁调节,保障电力系统稳定性并防止过载故障。

工业自动化

在包装机、机床等设备中,其快速响应能力(基于时间/事件中断)支持高效闭环控制,提升生产效率。

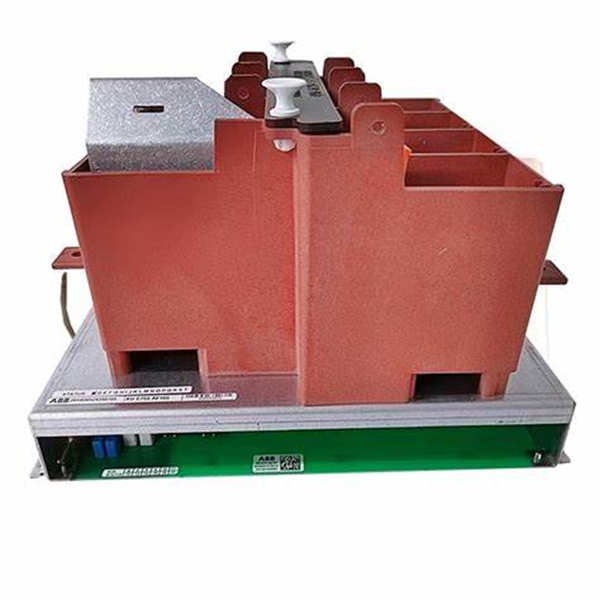

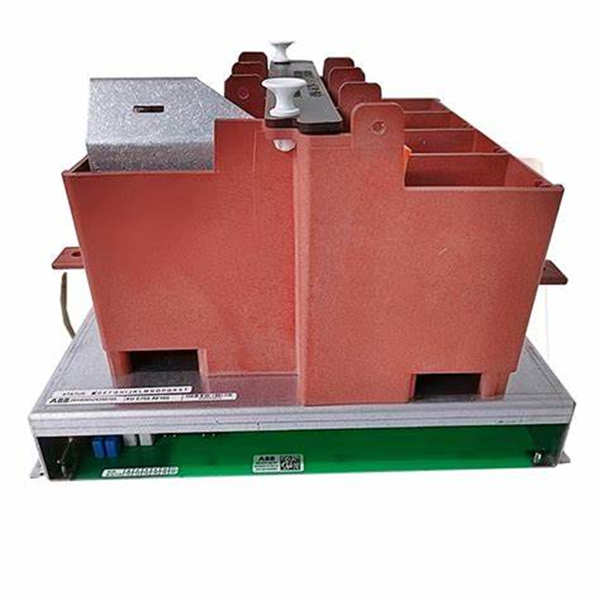

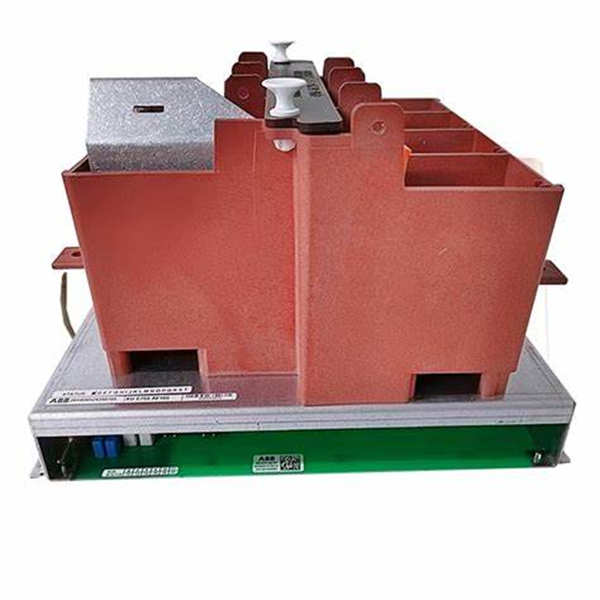

KUC755AE105 3BHB005243R0105

KUC755AE105 3BHB005243R0105

ABB KUC720AE01 is a high-performance inverter designed based on direct torque control(DTC)technology and widely used in industrial automation.The following is a comprehensive analysis of its core functions and technical features:

1.Core technology and performance

Direct torque control(DTC)

Use DTC technology to achieve precise control of motor speed and torque,with a response time of milliseconds,support full torque output at zero speed,and is suitable for frequent start-stop or high dynamic load scenarios.

Wide power coverage and flexibility

Provides a wide power range,compatible with a variety of industrial application requirements,supports potential loads(such as cranes,elevators),system transmission and precision control(such as angle/displacement adjustment).

Built-in PID controller

Integrated PID function simplifies control system design and reduces hardware costs,suitable for closed-loop position,speed or temperature regulation.

2.Functional features

Intelligent motor management

Motor identification function:Automatically identify motor parameters through IDRUN to optimize control performance.

Torque adaptation:In flux optimization mode,automatically adjust motor flux to improve efficiency and reduce noise,with efficiency improvement of up to 1%-10%.

Protection and reliability

Provides overload protection,short circuit protection and temperature protection,and supports redundant communication modules to enhance system stability.

Supports self-diagnosis function,and real-time feedback of operating status and fault information through LED indicators.

Expandability and communication interface

Integrates Ethernet,Profibus,Modbus and other protocols,and supports seamless connection with PLC,SCADA and other systems.

Provides 5 programmable output control terminals to flexibly adapt to the needs of different application scenarios.

III.Industry application cases

Steel metallurgy field

In the tundish electromagnetic stirring(EMS)system,KUC720AE01 uses non-contact electromagnetic technology to achieve homogenization of molten steel,significantly improves steel quality and reduces inclusions,and is applied to multi-stream continuous casting process.

Power system

Cooperates with the excitation control module for generator excitation regulation to ensure the stability of the power system and prevent overload faults.

Industrial automation

In packaging machines,machine tools and other equipment,its fast response capability(based on time/event interrupts)supports efficient closed-loop control and improves production efficiency.