描述

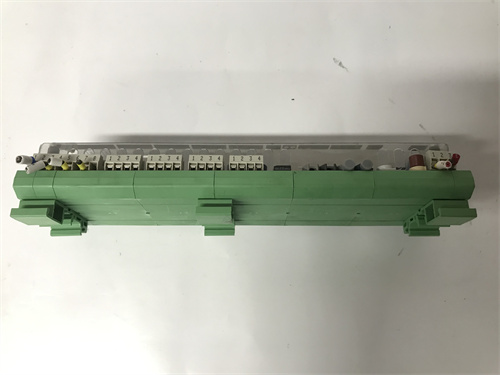

ABB NAMU-01C 64702475D产品详情

一、基本信息

品牌与型号:ABB NAMU-01C 64702475D

产品类型:控制器模块/辅助测量单元

应用场景:适用于工业自动化、电力系统监控、设备状态监测等场景,可作为变频器专用测量板或AC800M系统组件,满足高精度数据采集与控制需求。

二、技术规格

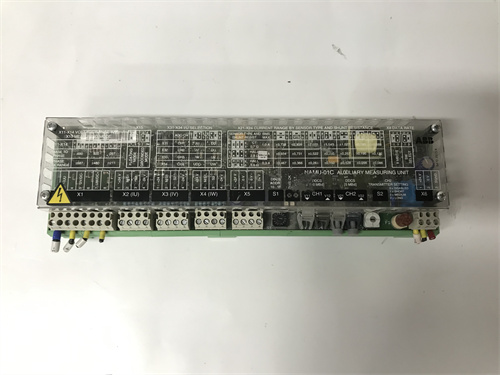

输入通道与传感器兼容性

通道配置:具备6个三线式传感器输入通道,支持100ΩPt和120ΩNi RTD、最高5kΩ电位计等多种传感器类型。

保护机制:每个通道配备240Vrms持续过载保护,符合ANSI/IEEE C37.90.1瞬态保护标准,防止接线错误导致设备损坏。

测量精度与隔离设计

精度保障:精度保证至满量程(f.s.),即小数点后第一位,支持传感器线性化处理以提升测量精度。

电气隔离:采用1500Vrms输入至总线隔离技术,增强系统抗干扰能力。

通信与扩展能力

接口支持:提供HDMI、RS485、Modbus、Profibus DP等通信接口,支持与PLC/DCS系统无缝集成。

存储与处理:内存扩展容量达128MB,支持用户脚本开发,可处理复杂控制逻辑。

三、功能特点

多通道灵活配置

支持为传感器、量程、报警限值和平均值单独配置通道,适应不同工业场景需求。

提供高、低、高-高、低-低四级报警功能,确保工艺流程安全。

抗干扰与自热优化

内置精密低幅度电流源,降低传感器自热效应,消除引线电阻误差。

每个通道可独立选择输入传感器类型和量程,支持超量程(2%)和欠量程保护。

高可靠性与环境适应性

符合重工业CE标准、UL/CUL认证及ATEX防爆标准(待定),适用于极端工业环境。

工作温度范围覆盖-40℃至100℃,防护等级达IP20,保障长期稳定运行。

四、应用场景

工业自动化控制

在制造业中用于驱动电机、监测设备状态,支持远程控制与数据采集。

适用于需要高精度模拟量输入的场景,如温度、压力、流量等参数监控。

电力系统监控

作为分布式控制系统(DCS)组件,实现发电厂、变电站的实时数据采集与故障预警。

支持多通道同步监测,提升电网运行的可靠性与效率。

设备状态监测

集成于大型机械设备的健康管理系统,通过振动、温度等参数分析预测设备故障。

支持多变量数据融合处理,为预防性维护提供决策依据。

ABB NAMU-01C 64702475D Product Details

I.Basic Information

Brand and Model:ABB NAMU-01C 64702475D

Product Type:Controller Module/Auxiliary Measurement Unit

Application Scenarios:Suitable for industrial automation,power system monitoring,equipment status monitoring and other scenarios.It can be used as a dedicated measurement board for inverters or AC800M system components to meet high-precision data acquisition and control requirements.

II.Technical Specifications

Input Channel and Sensor Compatibility

Channel Configuration:It has 6 three-wire sensor input channels,supporting a variety of sensor types such as 100ΩPt and 120ΩNi RTD,and up to 5kΩpotentiometers.

Protection Mechanism:Each channel is equipped with 240Vrms continuous overload protection,which complies with the ANSI/IEEE C37.90.1 transient protection standard to prevent equipment damage caused by wiring errors.

Measurement Accuracy and Isolation Design

Accuracy Guarantee:Accuracy is guaranteed to the full scale(f.s.),that is,the first decimal place,and supports sensor linearization processing to improve measurement accuracy.

Electrical isolation:1500Vrms input to bus isolation technology is used to enhance the system’s anti-interference ability.

Communication and expansion capabilities

Interface support:Provides communication interfaces such as HDMI,RS485,Modbus,Profibus DP,etc.,and supports seamless integration with PLC/DCS systems.

Storage and processing:The memory expansion capacity reaches 128MB,supports user script development,and can handle complex control logic.

III.Functional features

Multi-channel flexible configuration

Supports separate channel configuration for sensors,ranges,alarm limits and average valuesto meet the needs of different industrial scenarios.

Provides high,low,high-high,low-low four-level alarm functions to ensure process safety.

Anti-interference and self-heating optimization

Built-in precision low-amplitude current source to reduce sensor self-heating effect and eliminate lead resistance error.

Each channel can independently select input sensor type and range,and supports over-range(2%)and under-range protection.

High reliability and environmental adaptability

Complies with heavy industry CE standards,UL/CUL certification and ATEX explosion-proof standards(pending),suitable for extreme industrial environments.

The operating temperature range covers-40℃to 100℃,and the protection level reaches IP20,ensuring long-term stable operation.

IV.Application scenarios

Industrial automation control

In the manufacturing industry,it is used to drive motors,monitor equipment status,and support remote control and data acquisition.

Applicable to scenarios that require high-precision analog input,such as temperature,pressure,flow and other parameter monitoring.

Power system monitoring

As a distributed control system(DCS)component,it realizes real-time data acquisition and fault warning of power plants and substations.

Supports multi-channel synchronous monitoring to improve the reliability and efficiency of power grid operation.

Equipment status monitoring

Integrated in the health management system of large mechanical equipment,it predicts equipment failures through parameter analysis such as vibration and temperature.

Supports multi-variable data fusion processing to provide decision-making basis for preventive maintenance.